Exploring the Latest Trends and Pricing for GI Coupling Solutions in the Market Today

Understanding the Price Dynamics of GI Couplings

GI couplings, or Graphite Iron couplings, are critical components commonly used in various mechanical systems. They play a significant role in transmitting torque between shafts and accommodating misalignment in industrial applications. This article explores the factors influencing the price of GI couplings, market trends, and the implications for consumers and manufacturers.

Overview of GI Couplings

GI couplings are typically made from high-strength gray iron, known for its excellent vibration-damping properties, corrosion resistance, and overall durability. These features make GI couplings suitable for a wide range of applications, from automotive to manufacturing and beyond. The demand for these couplings has steadily increased due to their reliability and efficiency, which are paramount in high-performance environments.

Factors Influencing Price

1. Material Costs One of the primary factors affecting the price of GI couplings is the cost of materials. The price of graphite iron can fluctuate based on market dynamics, including raw material availability and global demand. Increases in the costs of raw materials due to supply chain disruptions or increased production costs can lead to higher prices for finished products.

2. Manufacturing Techniques The technology and processes used in the manufacturing of GI couplings also play a significant role in pricing. Advanced manufacturing techniques that enhance product quality or reduce waste can lead to higher initial investments but may lower operational costs over time. Companies that adopt innovative manufacturing processes may offer products at a premium, reflecting the added value.

3. Market Demand and Supply Dynamics The interaction between supply and demand is crucial for setting prices in any market, including that for GI couplings. An increase in infrastructure projects or machinery manufacturing can spur demand, driving prices higher. Conversely, if manufacturers overproduce or if there is a sudden drop in demand, prices may decrease.

gi coupling price

4. Competition The competitive landscape also affects pricing strategies for GI couplings. Companies may engage in price wars to capture market share, leading to lower prices. However, too much competition can also result in compromises on quality, which can have long-term effects on brand reputation and customer satisfaction.

5. Geographic Factors The location of manufacturers and their proximity to key markets can influence shipping costs, labor expenses, and overall pricing. Companies based in regions with lower production costs may offer more competitive pricing compared to those in high-cost areas.

Market Trends

As industries continue to evolve, several trends are shaping the pricing of GI couplings. The shift towards automation and increased reliance on advanced machinery in manufacturing is driving demand for high-quality components like GI couplings. Furthermore, the push for energy efficiency and sustainable practices is leading manufacturers to innovate, potentially affecting pricing structures.

Another trend worth noting is the growth of e-commerce, which facilitates easier access to a wider variety of suppliers. This expanded market access can lead to more competitive pricing as buyers can shop around, leading to more transparency in pricing for consumers.

Conclusion

The price of GI couplings is influenced by a myriad of factors, from raw material costs and manufacturing processes to market supply and demand dynamics. As industries continue to evolve and adapt to new technologies and market conditions, understanding these pricing factors becomes crucial for both manufacturers and consumers. Staying informed about market trends can help stakeholders make more strategic decisions, ultimately leading to improved operational efficiencies and cost savings. In a competitive landscape, the ability to navigate these pricing dynamics effectively can be a key differentiator for success.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

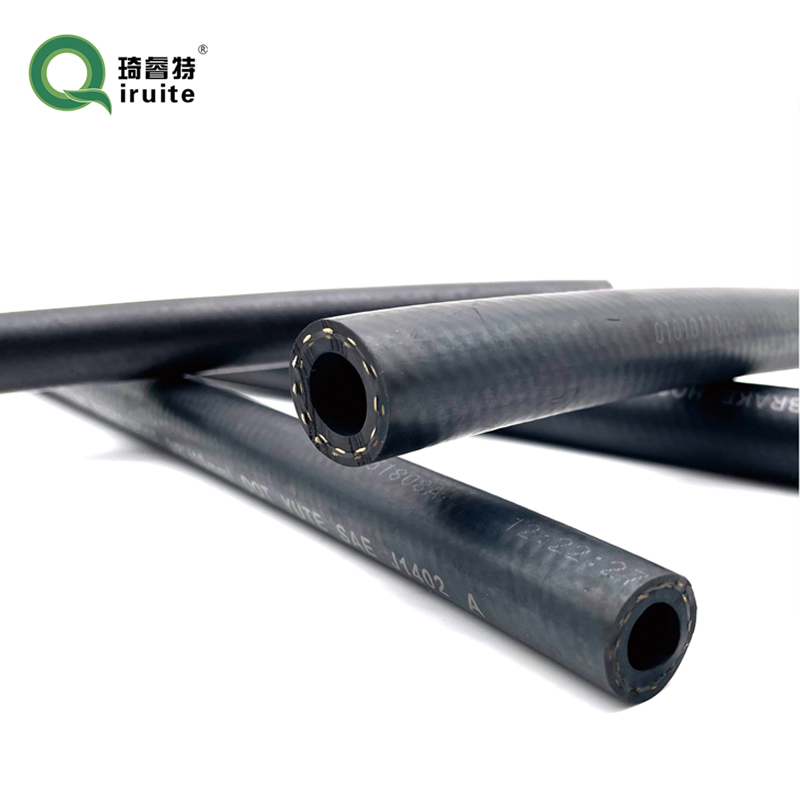

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025