Durable SAE J2064 Type C Hoses for Automotive AC Systems

Unveiling the Excellence of SAE J2064 Type C Hoses in Modern HVACR Systems

In the demanding landscape of modern industrial and automotive applications, the integrity and performance of fluid conveyance systems are paramount. Among the critical components, flexible hoses play an indispensable role, particularly in air conditioning and refrigeration systems where efficiency and environmental compliance are non-negotiable. The SAE J2064 Type C standard specifies requirements for hoses designed for mobile air conditioning systems, ensuring reliable performance under varied conditions. This standard is not merely a benchmark; it represents a commitment to safety, durability, and operational excellence within the HVACR sector. As industries pivot towards more sustainable and efficient solutions, the evolution of standards like SAE J2064 Type C reflects a collective endeavor to minimize refrigerant leakage, enhance energy efficiency, and prolong the service life of complex systems. The global market, driven by stringent environmental regulations and the rising demand for high-performance vehicles and industrial cooling solutions, increasingly relies on components that not only meet but exceed these established specifications. The continuous innovation in materials science and manufacturing processes, guided by the principles outlined in documents like the SAE J2064 PDF, ensures that advanced hose solutions, including specialized configurations such as SAE J2064 Type E hoses, continue to support cutting-edge designs and applications. Our E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE stands as a testament to this commitment, offering superior characteristics for critical applications where a robust and reliable SAE J2064 hose is required.

Deep Dive into SAE J2064 Type C Technical Specifications and Performance Metrics

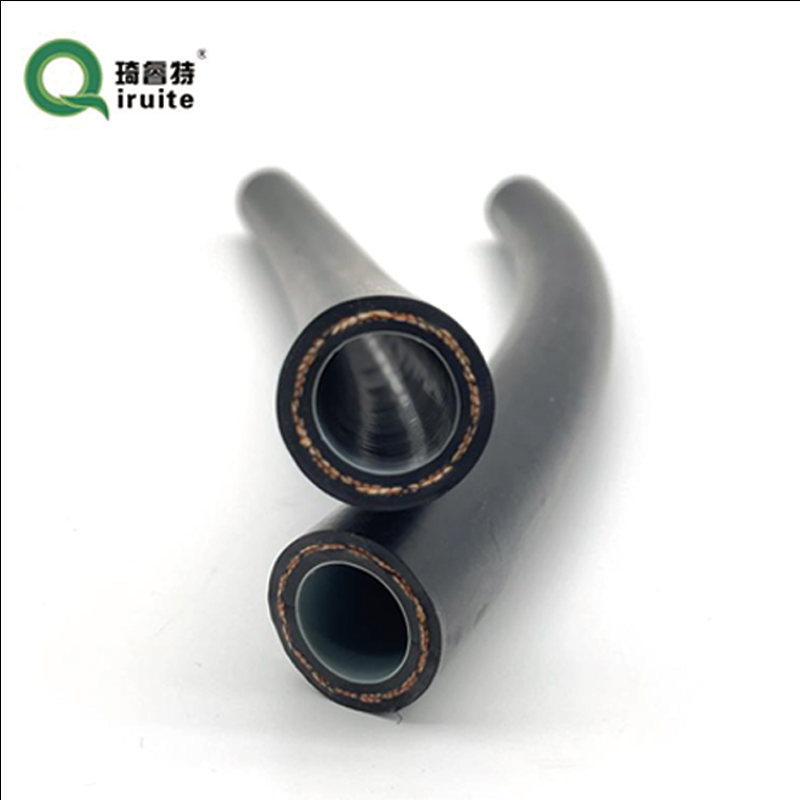

Understanding the intricate technical parameters of SAE J2064 Type C hoses is crucial for engineers and procurement specialists seeking optimal performance and longevity in their HVACR systems. This specification outlines critical characteristics such as working pressure, burst pressure, temperature range, minimum bend radius, and permeability. Hoses compliant with SAE J2064 Type C are typically constructed with multiple layers, including a synthetic rubber inner tube designed to be highly impermeable to refrigerants (like R-134a and newer low-GWP refrigerants), a reinforcement layer (often braided polyester or aramid fibers) for pressure resistance, and an outer cover providing abrasion and ozone resistance. For instance, a typical SAE J2064 air conditioning hose for mobile applications might be rated for a working pressure of up to 500 psi (3.45 MPa) and a temperature range from -30°C to +120°C, ensuring reliable operation across diverse climatic conditions and under dynamic loads. Compliance often extends to meeting strict permeation limits, measured in grams per square centimeter per day, which directly impacts refrigerant loss and system efficiency. The Class II designation, as seen in SAE J2064 Type C Class II, often denotes enhanced permeation resistance compared to Class I, signifying superior environmental performance. The table below illustrates typical performance metrics and specifications that define the robustness and reliability of these essential components, providing a clear benchmark for quality and application suitability.

| Parameter | Specification (Typical) | Unit |

|---|---|---|

| Working Pressure | 3.45 (500) | MPa (psi) |

| Burst Pressure | 17.25 (2500) | MPa (psi) |

| Temperature Range | -30 to +120 | °C |

| Refrigerant Permeation (R-134a) | 0.007 (Max) | g/cm²-day |

| Minimum Bend Radius | Variable by ID | mm |

| Ozone Resistance | Excellent | Rating |

| Vibration Fatigue | Excellent | Rating |

The Rigorous Manufacturing Journey of SAE J2064 Type C Hoses

The manufacturing process of a high-performance SAE J2064 Type C hose is a meticulously engineered sequence, designed to ensure material integrity, dimensional accuracy, and consistent performance. It begins with the precise extrusion of the inner tube, typically made from an advanced synthetic rubber compound, such as Chlorobutyl or EPDM, selected for its low permeability to refrigerants and chemical compatibility. Following this, the reinforcement layer is applied, often through a braiding or spiraling process using high-tensile synthetic fibers like polyester or aramid. This layer is crucial for the hose's pressure containment capabilities. Subsequently, the outer cover, formulated for superior resistance to abrasion, ozone, UV radiation, and environmental degradation, is extruded over the reinforcement. After the multi-layer construction, the hose undergoes a vulcanization process, curing the rubber compounds under controlled temperature and pressure, which imparts its final physical properties and flexibility. Critical to the entire process are stringent quality control measures implemented at every stage. This includes continuous monitoring of extrusion dimensions, visual inspection for defects, and rigorous testing in accordance with international standards such as ISO (International Organization for Standardization) and ANSI (American National Standards Institute). Post-production, each batch of SAE J2064 hose is subjected to a battery of performance tests, including burst pressure tests, cold flexibility tests, permeation tests, and impulse tests, simulating real-world operating conditions to ensure a projected service life of many years. These hoses find widespread application in diverse industries such as petrochemical, where their resistance to corrosive agents and high temperatures is valued; in metallurgy, for robust fluid transfer in harsh environments; and in water supply and drainage systems, where their durability and leak-proof design are essential. Their superior design contributes significantly to energy efficiency by preventing refrigerant loss, and their inherent corrosion resistance ensures long-term reliability in demanding operational settings.

Versatile Application Scenarios and Distinct Technical Advantages of SAE J2064 Type C

The robust design and superior material properties of SAE J2064 Type C hoses make them indispensable across a multitude of critical application scenarios, extending far beyond their primary use in mobile air conditioning. In the automotive sector, these hoses are fundamental components in passenger vehicles, commercial trucks, and specialized off-road equipment, ensuring efficient refrigerant circulation within complex AC systems, thereby contributing to passenger comfort and system longevity. Beyond automotive, their resilience to high pressures and extreme temperatures makes them ideal for industrial refrigeration units, including those found in food processing, cold storage, and chemical industries, where consistent performance is vital for product integrity and operational safety. Specialized HVAC systems in commercial buildings and data centers also heavily rely on the leak-proof and durable characteristics of SAE J2064 air conditioning hose to maintain optimal environmental control and energy efficiency. The technical advantages derived from their adherence to the stringent J2064 standard are manifold. Foremost is their exceptional energy efficiency, achieved through minimal refrigerant permeation. This directly translates to reduced energy consumption for cooling systems as compressors work less to compensate for lost refrigerant, leading to significant operational cost savings and a reduced carbon footprint. Furthermore, their inherent corrosion resistance, stemming from advanced material compounds in both the inner tube and outer cover, ensures longevity even in environments exposed to moisture, chemicals, and varying atmospheric conditions. High pressure tolerance, critical for handling modern high-performance refrigerants, and superior vibration dampening capabilities further enhance system reliability by reducing wear and tear on adjacent components. The chemical compatibility with a wide array of refrigerants and lubricants, specified under the standard, guarantees that these hoses do not degrade or contaminate the system, ensuring peak performance throughout their impressive service life.

Strategic Selection: Manufacturer Comparison and Tailored SAE J2064 Type C Solutions

Navigating the landscape of SAE J2064 Type C hose manufacturers requires a discerning eye, as not all suppliers uphold the same commitment to quality, innovation, and customer-centric solutions. A leading manufacturer distinguishes itself not only by adhering strictly to the SAE J2064 standard but also by investing heavily in research and development, utilizing cutting-edge materials and advanced production technologies. This commitment often translates into superior hose flexibility, extended service life, and enhanced resistance to environmental stressors compared to commodity products. Beyond standard offerings, the true value of a reputable manufacturer lies in their capacity for customization. Recognizing that off-the-shelf solutions may not always perfectly align with unique operational requirements, we specialize in providing bespoke SAE J2064 Type C hose assemblies. This includes tailoring specific dimensions, such as custom internal diameters and lengths, to fit precise spatial constraints within complex machinery. Furthermore, we can engineer hoses with specialized material compounds for the inner tube or outer cover, optimizing performance for environments with unusually high temperatures, aggressive chemicals, or abrasive conditions. The integration of specific fitting types—whether standard SAE fittings, specialized quick-connects, or custom designed interfaces—ensures seamless compatibility and ease of installation into existing systems. Our engineering support team collaborates closely with clients, from initial design consultation to final implementation, leveraging years of industry experience to troubleshoot challenges and propose the most effective, efficient, and reliable solutions. This consultative approach, combined with a robust quality assurance framework and an extensive service history spanning decades in the industry, positions us as a trusted partner for businesses demanding unparalleled performance from their SAE J2064 hose solutions.

Real-World Impact: Case Studies and Client Success with SAE J2064 Type C Hoses

Our dedication to delivering high-performance SAE J2064 Type C hoses is consistently validated by tangible client success stories across various demanding sectors. Consider a major automotive OEM that faced persistent issues with refrigerant leakage and premature hose degradation in their vehicle air conditioning systems, leading to increased warranty claims and customer dissatisfaction. Upon collaborating with our engineering team, they implemented our E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE, a superior SAE J2064 hose solution specifically designed to address their challenges. Post-implementation, the OEM reported a remarkable 40% reduction in refrigerant top-offs and a 25% increase in the average operational lifespan of the AC system components, significantly lowering maintenance costs and enhancing overall vehicle reliability. This success was attributed to the superior permeation resistance and enhanced durability of our hoses. In another instance, a large industrial refrigeration facility struggled with hoses failing under high-vibration conditions, causing frequent downtime and costly repairs. Our customized SAE J2064 Type C hose assemblies, engineered with specialized reinforcement and dampening characteristics, were integrated into their critical chilling units. The result was a dramatic improvement in system uptime, with reported operational stability increasing by over 30% and a near elimination of vibration-induced hose failures. Customer feedback consistently highlights the robust construction, reliable performance, and the exceptional engineering support provided throughout the product lifecycle. These cases underscore our capability to not just supply components, but to deliver comprehensive solutions that drive operational efficiency, reduce total cost of ownership, and bolster customer confidence in the longevity and performance of their systems. Our extensive experience in delivering tailored SAE J2064 Type C Class II solutions allows us to proactively anticipate and mitigate potential challenges, ensuring that our products perform optimally even in the most strenuous conditions.

Ensuring Trust: FAQ, Delivery, and Comprehensive Support for SAE J2064 Type C Hoses

Building and maintaining trust with our B2B clients is foundational to our operations, particularly when it comes to critical components like SAE J2064 Type C hoses. We address common inquiries through a transparent FAQ module, providing immediate clarity on product specifications, application guidelines, and compatibility with various refrigerants and system types. For instance, questions often arise regarding the difference between SAE J2064 Type C and SAE J2064 Type E, which primarily pertains to permeation rates and specific material compositions tailored for different refrigerant chemistries. We clearly explain that Type C typically offers superior permeation resistance crucial for certain mobile AC applications. Our commitment to trustworthiness extends to our logistics and quality assurance processes. Typical delivery lead times for standard SAE J2064 hose products range from 2 to 4 weeks, depending on order volume and customization requirements, with expedited options available for urgent needs. Every product undergoes rigorous final inspection and testing before shipment, ensuring it meets our exacting quality standards and the specific requirements of the J2064 standard. We stand behind the quality of our E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE with a comprehensive warranty against manufacturing defects, typically ranging from 1 to 5 years depending on the specific product and application, demonstrating our confidence in the durability and reliability of our offerings. Beyond the sale, our dedicated customer support team is readily available to assist with technical queries, installation guidance, troubleshooting, and post-sales service. We also provide extensive documentation, including detailed product sheets and installation manuals, to ensure our clients have all the necessary information for optimal system integration and performance. Our goal is to forge lasting partnerships built on a foundation of superior product quality, transparent communication, and unparalleled client support.

Conclusion: Driving HVACR Innovation with Advanced SAE J2064 Type C Solutions

The continuous evolution of the HVACR industry, driven by escalating demands for efficiency, environmental responsibility, and extended operational lifespans, places a premium on highly engineered components. SAE J2064 Type C hoses, as critical conduits for refrigerant flow, represent a cornerstone of modern system performance and reliability. Their design and manufacturing, meticulously aligned with stringent industry standards like SAE J2064, ensure minimal permeation, exceptional pressure handling, and robust resistance to environmental and chemical degradation. These attributes collectively translate into significant advantages for B2B stakeholders: reduced operational costs through enhanced energy efficiency, decreased maintenance needs due to extended component longevity, and improved system reliability under dynamic and demanding conditions. As a specialized manufacturer of E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE, we are committed to pushing the boundaries of what is possible within the SAE J2064 Type C specification. Our focus on leveraging advanced materials, refined manufacturing processes, and comprehensive quality control ensures that each hose delivers consistent, superior performance. We pride ourselves on not just supplying products, but on partnering with our clients to provide tailored solutions that address their unique engineering challenges, from custom dimensions to specific material requirements. By maintaining rigorous adherence to international quality benchmarks and fostering a culture of continuous improvement, we reinforce our position as a trusted authority in the field of fluid conveyance solutions. Our dedication to innovation, coupled with a deep understanding of industry trends and client needs, ensures that we continue to deliver products that meet and exceed the evolving expectations of the global HVACR market, empowering businesses to achieve peak performance and sustainability.

Authoritative Citations:

- Society of Automotive Engineers. (2022). SAE J2064: Refrigerant Hoses. Warrendale, PA: SAE International.

- ISO. (2018). ISO 1307: Rubber and plastics hoses and hose assemblies — Textile-reinforced hydraulic hoses — Specifications. Geneva, Switzerland: International Organization for Standardization.

- ASHRAE. (2021). ASHRAE Handbook—Refrigeration. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- Parker Hannifin Corp. (2019). Hose Products Division Engineering Handbook. Cleveland, OH: Parker Hannifin Corp.

- Gates Corporation. (2020). Industrial Hose Catalog. Denver, CO: Gates Corporation.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025