ducting hose connector

Understanding Ducting Hose Connectors A Comprehensive Guide

Ducting hose connectors play a vital role in various industries, from HVAC systems to industrial exhaust applications. These connectors are essential components that facilitate the seamless connection of ducting hoses, allowing for efficient airflow and the safe transportation of materials. This article aims to provide an overview of ducting hose connectors, their types, applications, and the factors to consider when choosing the right connector for your needs.

What Are Ducting Hose Connectors?

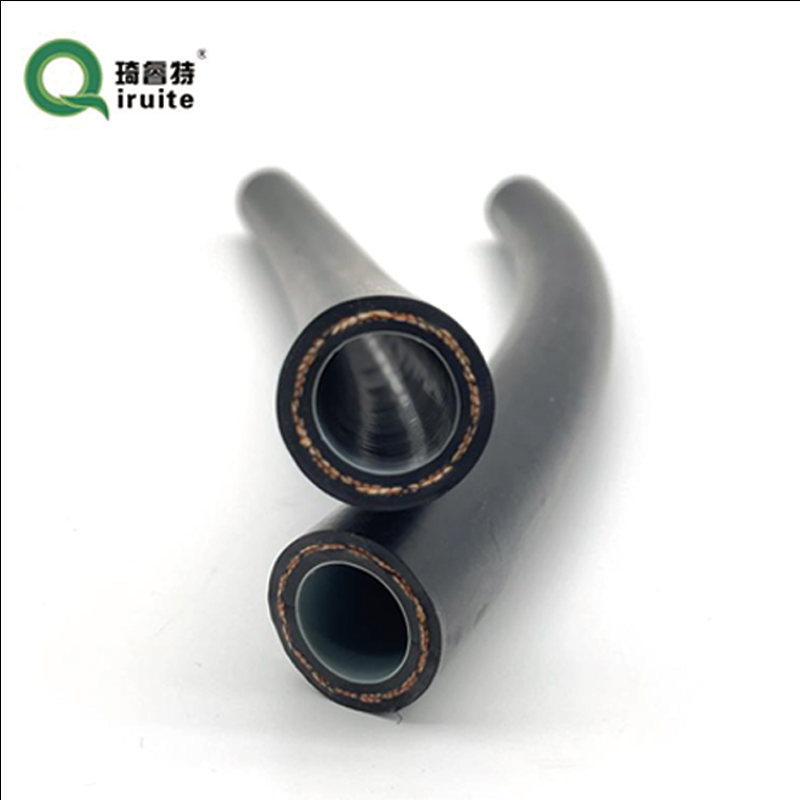

Ducting hose connectors are fittings designed to join two or more sections of ducting hose. They are crucial for creating airtight seals that prevent leaks, which can significantly affect system efficiency and performance. These connectors can be made from various materials, including plastic, metal, and rubber, each offering unique advantages depending on the application.

Types of Ducting Hose Connectors

There are several types of ducting hose connectors, each suited for specific applications

1. Spring Wire Connectors These connectors utilize a spring wire to create a secure fit around the hose. They are often used in flexible ducting applications due to their ability to maintain a strong grip.

2. Clamp Connectors These use mechanical clamps to secure the hose to the connector. Clamp connectors are versatile and commonly found in both industrial and residential settings.

3. Flanged Connectors Flanged connectors have flat surfaces that can be bolted together. They provide a tight seal and are perfect for high-pressure applications, commonly seen in HVAC systems.

ducting hose connector

4. Quick Release Connectors These connectors allow for easy and quick assembly and disassembly. They are ideal in situations where hoses need to be frequently connected and disconnected.

5. Rubber and PVC Connectors Made from durable materials, these connectors are resistant to wear and tear. They are widely used in environments where hoses are exposed to chemicals or extreme temperatures.

Applications of Ducting Hose Connectors

Ducting hose connectors are used in numerous applications, including

- HVAC Systems They connect ducts and hoses for ventilation, heating, and air conditioning, ensuring proper airflow. - Industrial Exhaust Used in factories to extract fumes and smoke, they help maintain air quality and comply with regulations. - Agriculture In agricultural settings, ducting connectors are used for dust collection and ventilation in greenhouses and livestock facilities. - Food Processing Food-grade connectors ensure that the transfer of materials meets hygiene and safety standards.

Choosing the Right Ducting Hose Connector

When selecting a ducting hose connector, several factors should be considered

1. Material Compatibility Ensure that the connector's material is suitable for the substances being transported. 2. Diameter and Size The connector must match the diameter of the hoses to prevent leaks and ensure optimal performance. 3. Pressure Rating Choose connectors that can withstand the pressure requirements of your application. 4. Ease of Installation If frequent connections and disconnections are necessary, opt for quick-release or easy-to-install connectors.

In conclusion, ducting hose connectors are indispensable components across various industries, ensuring efficient and safe systems. By understanding the different types, applications, and selection criteria, you can make informed decisions for your specific needs, ultimately enhancing performance and reliability in your operations.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025