coupling connector pipe

Understanding Coupling Connector Pipes A Comprehensive Overview

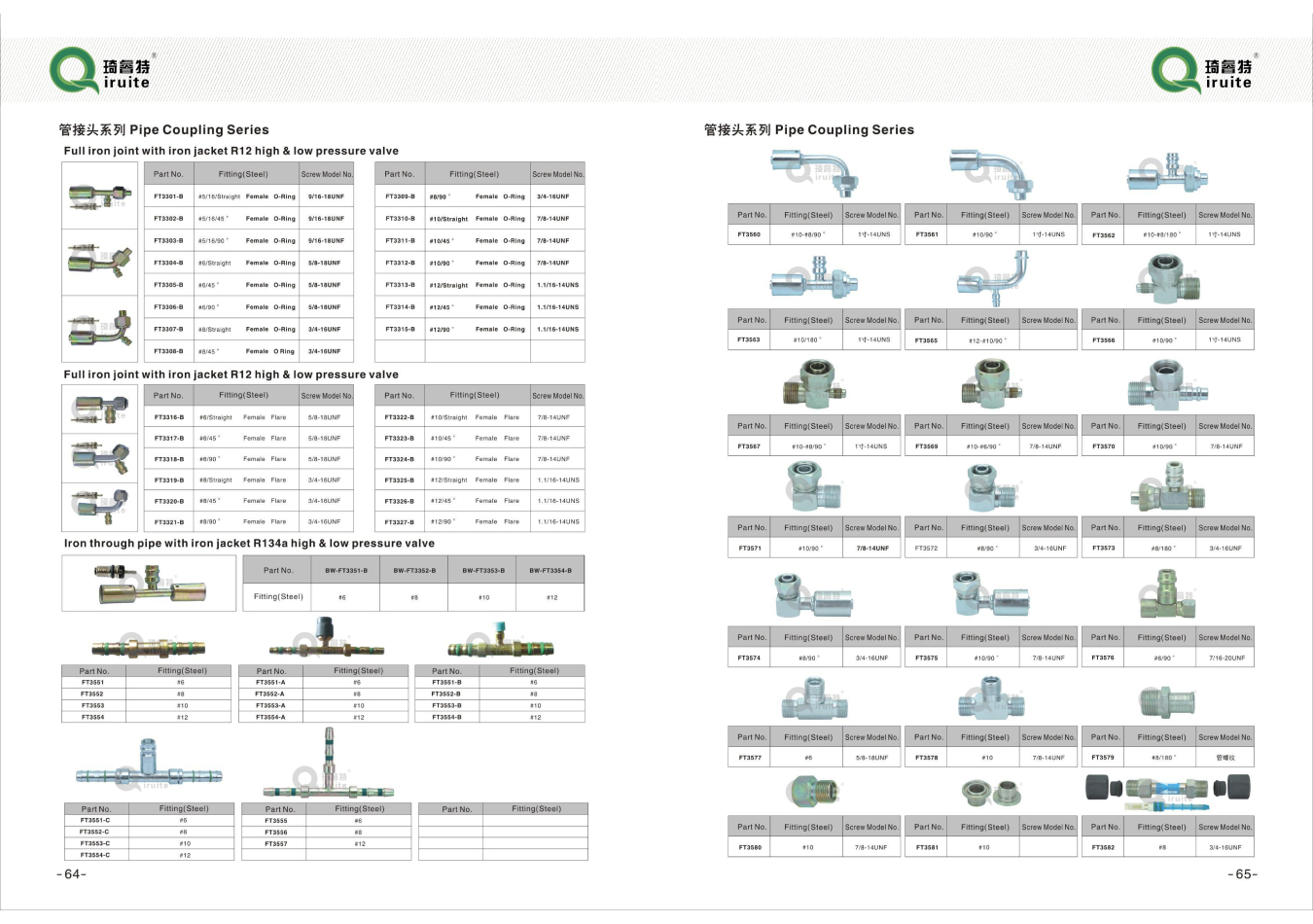

Coupling connector pipes play a crucial role in various industries, including construction, plumbing, and manufacturing. These essential components are designed to link sections of pipes together, ensuring a seamless and efficient fluid flow. In this article, we will explore the different types of coupling connector pipes, their applications, and the benefits they provide.

Coupling connectors come in various forms, including threaded, slip, weld, and mechanical types. Threaded couplings are particularly popular in plumbing, as they allow for easy disassembly and reassembly without the need for specialized tools. Slip couplings are commonly used for aligning pipes of the same diameter, making them ideal for repair work. Weld couplings, on the other hand, offer a permanent connection, providing durability for high-pressure applications. Mechanical couplings are versatile and can accommodate slight misalignments, making them useful in various piping configurations.

The materials used in coupling connector pipes vary based on the application. Common materials include PVC, copper, stainless steel, and carbon steel. Each material offers distinct advantages. For instance, PVC is lightweight and resistant to corrosion, making it suitable for chemical transport. Copper is favored for its antibacterial properties and efficiency in water supply systems. Steel options, including stainless steel, are known for their strength and longevity, making them ideal for industrial applications.

coupling connector pipe

The applications of coupling connector pipes are extensive. In plumbing and irrigation systems, they facilitate water distribution by connecting pipes of different lengths and diameters. In industrial settings, these connectors are crucial for fluid and gas transport systems, ensuring safety and efficiency. They are also used in HVAC systems, where they help in creating connections for air and refrigerant ducts, contributing to climate control in residential and commercial buildings.

The benefits of using coupling connector pipes cannot be overstated. They enhance the integrity of piping systems by providing secure connections that minimize leaks and spills. Additionally, they offer flexibility in design, allowing for easy modifications and repairs as needed. Their ease of installation can significantly reduce labor costs and construction timelines.

In conclusion, coupling connector pipes are indispensable in maintaining the integrity and efficiency of piping systems across various industries. Understanding their types, materials, and applications can help professionals make informed choices, ensuring reliable performance in their respective projects. As technology advances, the design and manufacturing of these components continue to evolve, promising even greater efficiency and effectiveness in the years to come.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025