Concrete Pipe Connector Solutions for Enhanced Durability and Seamless Integration

Understanding Concrete Pipe Couplings An Essential Component in Construction

Concrete pipe couplings play a crucial role in the construction and infrastructure sectors, offering seamless connections between different sections of concrete pipes. These couplings are designed to ensure the stability and integrity of piping systems used in various applications, including drainage, sewage systems, and stormwater management. In this article, we will explore the importance of concrete pipe couplings, their types, installation procedures, and the benefits they provide.

What Are Concrete Pipe Couplings?

Concrete pipe couplings are specialized fittings used to connect two sections of concrete pipes. They are essential for creating a secure, watertight seal that prevents leaks and soil erosion, especially in underground applications. Made from durable materials, these couplings are engineered to withstand environmental stresses, ensuring long-term performance in various operating conditions.

Types of Concrete Pipe Couplings

There are several types of concrete pipe couplings, each designed for specific applications and pipe sizes

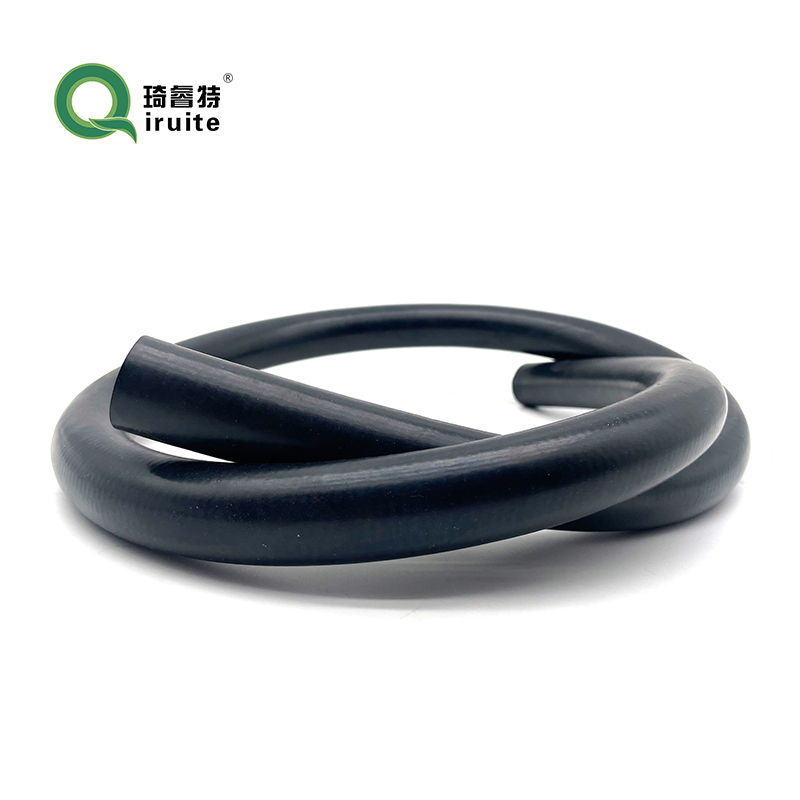

1. Flexible Couplings These couplings allow for slight movements between pipe sections due to ground settlement or thermal expansion. They are made from flexible materials such as rubber or elastomeric compounds, providing a secure seal and accommodating misalignments.

2. Rigid Couplings Rigid couplings are designed for strong, fixed connections between pipes. They are typically made from reinforced concrete or metal and are ideal for applications where flexibility is not a primary concern.

3. Dowel Couplings Dowel couplings utilize steel dowels or rods to connect two pipes, ensuring alignment and providing additional strength at the joint. This type is commonly used in larger diameter pipes where structural integrity is paramount.

4. Flanged Couplings These couplings feature flanges on both ends, allowing for mechanical fastening with bolts. Flanged couplings are often used in high-pressure systems, where a secure connection is critical to avoid leaks.

Installation Procedures

Proper installation of concrete pipe couplings is essential for ensuring their effectiveness and longevity. The following steps outline the typical installation process

1. Preparation Before installation, the pipe ends must be cleaned and inspected for damage. Any debris or loose material should be removed to ensure a proper seal.

concrete pipe coupling

2. Alignment The pipes must be aligned carefully to ensure that they fit together correctly. Misalignment can lead to leaks and structural weaknesses.

3. Insertion of the Coupling The coupling is then positioned between the pipe ends. If a flexible coupling is being used, it is essential to ensure that it is correctly aligned to accommodate any movements that may occur.

4. Securing the Connection Depending on the type of coupling, bolts may need to be tightened, or adhesive materials may be applied to secure the connection. The goal is to create a tight, watertight seal without over-stressing the pipes.

5. Testing After the installation, it is vital to conduct pressure tests or inspections to ensure that the connection is secure and leak-free.

Benefits of Concrete Pipe Couplings

Concrete pipe couplings offer numerous benefits that enhance the efficiency and durability of piping systems

1. Enhanced Durability By providing a sturdy connection, these couplings increase the lifespan of the piping system, reducing the need for frequent repairs.

2. Leak Prevention The watertight seal created by couplings helps prevent leaks, which can lead to significant environmental issues and costly repairs.

3. Ease of Maintenance Couplings allow for easier maintenance and replacement of individual pipe sections without the need for extensive excavation.

4. Flexibility and Adaptability Flexible couplings, in particular, accommodate ground movements and thermal expansion, making them suitable for various geological settings.

5. Cost-Effectiveness Although the upfront costs may be higher compared to other materials, the long-term savings from reduced repairs and maintenance make concrete pipe couplings a cost-effective choice.

Conclusion

Concrete pipe couplings are indispensable components in modern construction and infrastructure projects. Their ability to provide secure, watertight connections between concrete pipes ensures the integrity of drainage and sewage systems while enhancing the overall durability of the infrastructure. By understanding the different types of couplings available and following proper installation procedures, contractors can ensure that these vital components perform optimally, contributing to the safety and longevity of essential services. As construction technologies continue to advance, the importance of quality materials and connections like concrete pipe couplings remains a priority for engineers and builders alike.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025