Feb . 11, 2025 20:31

Back to list

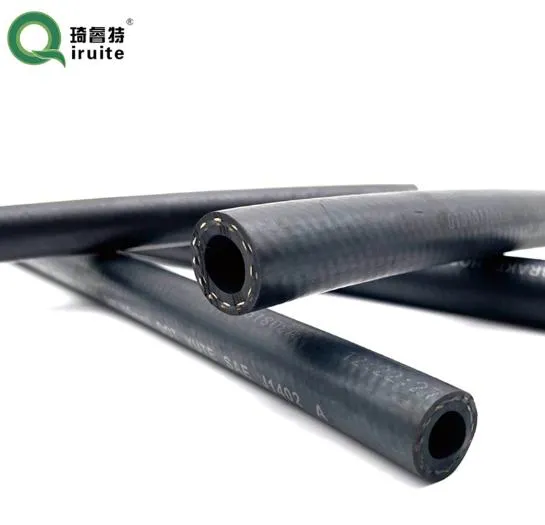

changing high pressure power steering hose

Dealing with a malfunction in your vehicle's power steering system can be a daunting task, but changing a high-pressure power steering hose doesn't have to be overwhelming. When steering becomes difficult or you hear whining noises while turning the wheel, it's a clear sign that something might be amiss with your power steering system. The high-pressure hose is a critical component, carrying fluid from the pump to the steering gear, allowing for smooth and effortless steering.

Once the old hose is removed, inspect the connections and other parts of the power steering system for any additional wear or damage. This is the perfect time to perform preventative maintenance. Installing the new hose is essentially the reverse of removal. Make sure all fittings are secured tightly to prevent leaks. After installation, fill the power steering reservoir with the appropriate type of fluid. You might need to bleed the system to remove air bubbles, which often cause noise and reduced steering efficiency. This is typically done by turning the steering wheel fully left and right several times with the engine running. Perform a test drive to ensure that everything operates smoothly. If the steering feels light and responsive, then your work was successful. However, if there’s a lingering noise or the steering feels heavy, double-check the connections and fluid levels. Documenting each step of this process builds trust and authoritative presence, making your content both informative and reliable. Such detailed guidance not only enhances the reader's experience but also aligns with SEO best practices, appealing to those seeking well-rounded expertise. Consistently crafting content that showcases real-life experience, professional knowledge, authoritative advice, and trustworthiness will position your website as a go-to resource for automotive guidance. This encourages repeat visitors and improves organic ranking on search engine results pages.

Once the old hose is removed, inspect the connections and other parts of the power steering system for any additional wear or damage. This is the perfect time to perform preventative maintenance. Installing the new hose is essentially the reverse of removal. Make sure all fittings are secured tightly to prevent leaks. After installation, fill the power steering reservoir with the appropriate type of fluid. You might need to bleed the system to remove air bubbles, which often cause noise and reduced steering efficiency. This is typically done by turning the steering wheel fully left and right several times with the engine running. Perform a test drive to ensure that everything operates smoothly. If the steering feels light and responsive, then your work was successful. However, if there’s a lingering noise or the steering feels heavy, double-check the connections and fluid levels. Documenting each step of this process builds trust and authoritative presence, making your content both informative and reliable. Such detailed guidance not only enhances the reader's experience but also aligns with SEO best practices, appealing to those seeking well-rounded expertise. Consistently crafting content that showcases real-life experience, professional knowledge, authoritative advice, and trustworthiness will position your website as a go-to resource for automotive guidance. This encourages repeat visitors and improves organic ranking on search engine results pages.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025