Jan . 20, 2025 09:26

Back to list

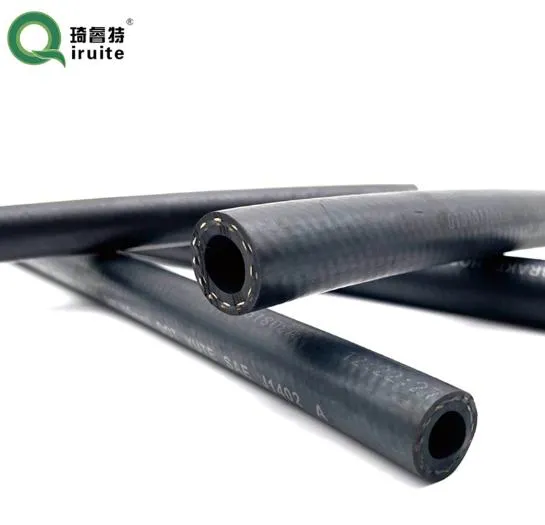

brake hose sae j1401

Choosing the right brake hose assembly for your vehicle is crucial to ensuring safety and performance on the road. Brake hoses serve as the conduits for hydraulic fluid, transmitting the force from the brake pedal to the braking mechanism, effectively halting your car with precision. Not only do they need to withstand immense pressure, but they must also be resilient against various environmental factors such as temperature fluctuations and exposure to dirt, debris, and moisture.

Leading authoritative sources recommend regular inspections of brake hoses as part of your vehicle’s maintenance routine. Indicators of wear such as visible cracks, leaks, or abrasions should be addressed immediately. Trustworthy mechanics will advise replacing brake hoses every four to five years or according to the manufacturer’s recommendations, even if visible damage is not apparent. It's worth noting that preventive maintenance not only extends the life of your brake system but enhances overall vehicle safety. In the realm of aftermarket parts, selecting a reputable brand for your brake hose assembly is synonymous with ensuring reliability and performance. Brands with a strong market reputation often provide detailed product information, including compatibility data, pressure ratings, and warranty terms. These details reflect a commitment to quality and build consumer trust. Choices are plenty, but investing in a recognized brand could safeguard against future repair costs or potential failures. Ultimately, the conscientious selection, expert installation, and regular maintenance of brake hose assemblies are pivotal in guaranteeing a responsive and safe braking system. By focusing on these aspects, you assure not only the longevity of your vehicle’s brake system but also the safety of every journey. The synthesis of professional knowledge, quality components, and routine care emphasizes a holistic approach to vehicle maintenance that every vehicle owner should prioritize.

Leading authoritative sources recommend regular inspections of brake hoses as part of your vehicle’s maintenance routine. Indicators of wear such as visible cracks, leaks, or abrasions should be addressed immediately. Trustworthy mechanics will advise replacing brake hoses every four to five years or according to the manufacturer’s recommendations, even if visible damage is not apparent. It's worth noting that preventive maintenance not only extends the life of your brake system but enhances overall vehicle safety. In the realm of aftermarket parts, selecting a reputable brand for your brake hose assembly is synonymous with ensuring reliability and performance. Brands with a strong market reputation often provide detailed product information, including compatibility data, pressure ratings, and warranty terms. These details reflect a commitment to quality and build consumer trust. Choices are plenty, but investing in a recognized brand could safeguard against future repair costs or potential failures. Ultimately, the conscientious selection, expert installation, and regular maintenance of brake hose assemblies are pivotal in guaranteeing a responsive and safe braking system. By focusing on these aspects, you assure not only the longevity of your vehicle’s brake system but also the safety of every journey. The synthesis of professional knowledge, quality components, and routine care emphasizes a holistic approach to vehicle maintenance that every vehicle owner should prioritize.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025