Jan . 26, 2025 02:08

Back to list

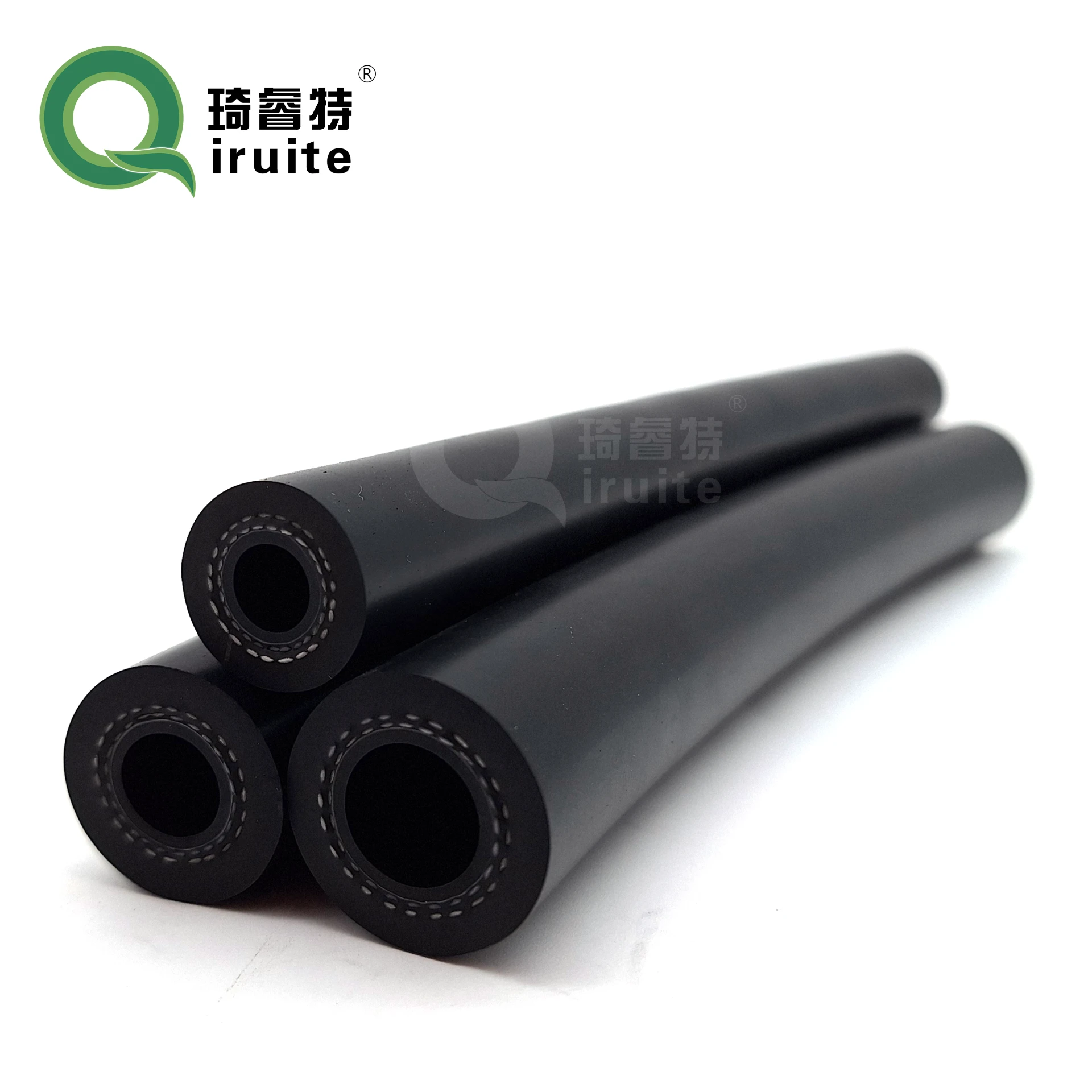

SAE J1401 Brake Hose

Black pipe coupling is crucial in joining various sections of pipes in plumbing and other industrial systems. These components are often overshadowed by more complex mechanisms, but they play a vital role in ensuring the seamless flow of substances through networks of black pipes. Through firsthand experience and a wealth of expertise in this domain, this article elucidates the importance, functionality, and application of black pipe couplings, embedding the authoritative insights needed to choose the right component for diverse needs.

Trustworthiness in black pipe coupling not only emanates from adherence to standards but also from real-world performance. Reviews and field tests from professionals consistently highlight the importance of the coupling's fit and finish. Tight tolerances and smooth threading are often cited as characteristics of a high-quality coupling that minimizes leakage risk. Furthermore, feedback loops from the field—where users report back on long-term performance—help improve future designs and meet evolving demands in plumbing and industrial applications. For installations involving black pipe couplings, professional training and knowledge-sharing are invaluable. Plumbers and construction engineers often undergo specialized training that covers the nuances of installing and maintaining these components. Skillful installation ensures that couplings are not overtightened, which could inadvertently cause thread stripping or damage material integrity. On-the-job experience provides insights that cannot be replicated in written manuals, emphasizing the importance of learning from skilled practitioners. Beyond installation, regular maintenance checks serve an ongoing role in ensuring the optimal performance of black pipe systems. Examining couplings for signs of wear, corrosion, or improper alignment can prevent small issues from escalating into significant problems, like system leaks or failures. The life span of a black pipe coupling heavily depends on the consistency of maintenance, reinforcing the importance of routine inspections across complex piping networks. In summation, while often overlooked, black pipe couplings are indispensable for ensuring the durability and effectiveness of piping systems in various applications, from residential installations to large-scale industrial projects. A thorough understanding of their application, supported by standardized expertise and maintenance protocols, empowers users to make informed choices. This awareness fosters a serviceable and reliable infrastructure that meets modern demands and sustains long-term system integrity.

Trustworthiness in black pipe coupling not only emanates from adherence to standards but also from real-world performance. Reviews and field tests from professionals consistently highlight the importance of the coupling's fit and finish. Tight tolerances and smooth threading are often cited as characteristics of a high-quality coupling that minimizes leakage risk. Furthermore, feedback loops from the field—where users report back on long-term performance—help improve future designs and meet evolving demands in plumbing and industrial applications. For installations involving black pipe couplings, professional training and knowledge-sharing are invaluable. Plumbers and construction engineers often undergo specialized training that covers the nuances of installing and maintaining these components. Skillful installation ensures that couplings are not overtightened, which could inadvertently cause thread stripping or damage material integrity. On-the-job experience provides insights that cannot be replicated in written manuals, emphasizing the importance of learning from skilled practitioners. Beyond installation, regular maintenance checks serve an ongoing role in ensuring the optimal performance of black pipe systems. Examining couplings for signs of wear, corrosion, or improper alignment can prevent small issues from escalating into significant problems, like system leaks or failures. The life span of a black pipe coupling heavily depends on the consistency of maintenance, reinforcing the importance of routine inspections across complex piping networks. In summation, while often overlooked, black pipe couplings are indispensable for ensuring the durability and effectiveness of piping systems in various applications, from residential installations to large-scale industrial projects. A thorough understanding of their application, supported by standardized expertise and maintenance protocols, empowers users to make informed choices. This awareness fosters a serviceable and reliable infrastructure that meets modern demands and sustains long-term system integrity.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025