air pipe coupling

Understanding Air Pipe Coupling An Essential Component in Pneumatic Systems

Air pipe coupling plays a crucial role in various industries where pneumatic systems are prevalent. These systems rely on compressed air to function effectively, powering everything from simple tools to complex machinery. Understanding the importance and functionality of air pipe couplings is essential for ensuring operational efficiency and safety.

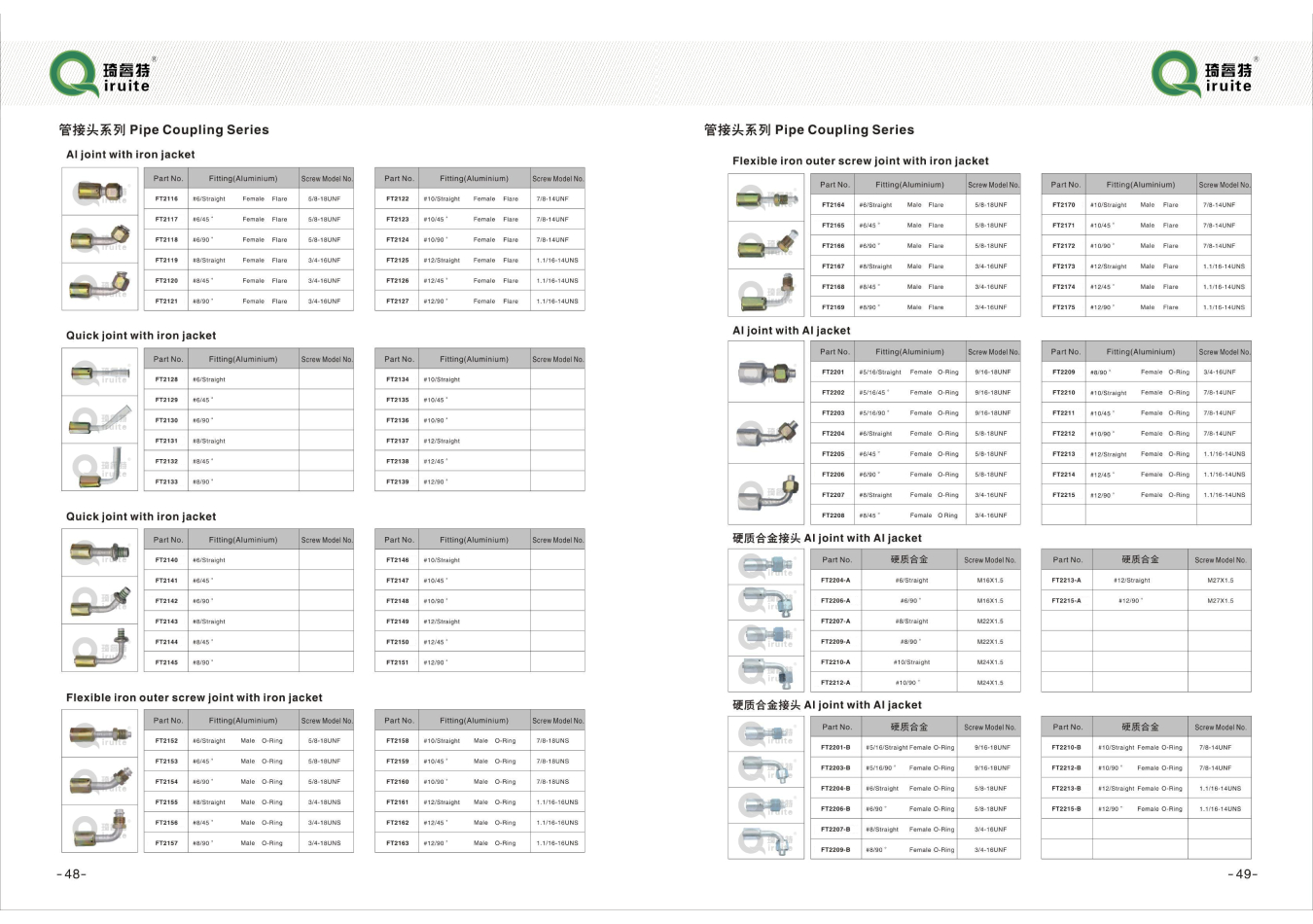

Air pipe couplings are designed to connect sections of pipe that transport compressed air from one location to another. These couplings come in various shapes and sizes, facilitating the seamless transfer of air while allowing for easy disconnection when necessary. They are constructed from durable materials such as brass, stainless steel, or plastic, depending on the application requirements and environmental conditions.

One of the key advantages of using air pipe couplings is their ability to create a secure and leak-proof connection. This is particularly important in pneumatic systems where any loss of pressure can lead to decreased performance and efficiency. High-quality couplings are engineered to withstand high pressures and extremes of temperature, ensuring that the system remains functional under varying operational conditions.

air pipe coupling

The installation of air pipe couplings is relatively straightforward, making them an attractive option for many applications

. However, proper installation is critical to avoid potential issues such as air leaks. Installation usually involves aligning the pipes correctly and tightening the couplings to the specified torque levels. Additionally, regular inspection and maintenance are advised to ensure that wear and tear do not compromise their effectiveness over time.Beyond their basic function of connecting pipes, air pipe couplings are also equipped with features that enhance their usability. Some couplings come with quick-release mechanisms, allowing for fast disconnections when tools or machinery need to be serviced or replaced. Others may include built-in check valves that prevent backflow, further ensuring the efficiency of the pneumatic system.

Moreover, air pipe couplings are versatile and can be adapted for a wide range of applications. From manufacturing and construction sites to automotive workshops, these couplings are integral to any setup that relies on pneumatic power. Their ability to facilitate the transport of air in a safe and efficient manner contributes significantly to the overall productivity of the operations.

In conclusion, air pipe couplings are an indispensable component of pneumatic systems, offering a reliable and versatile solution for connecting air pipes. Their robust construction, ease of installation, and additional features make them essential for maintaining system efficiency and safety. For any industry that utilizes compressed air, investing in high-quality air pipe couplings is a wise choice that can yield long-term benefits. Proper understanding and maintenance of these couplings are necessary to ensure the smooth operation of pneumatic systems, ultimately leading to enhanced productivity and operational success.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025