Air Conditioning Hose Connectors for Optimal Performance and Efficiency

Understanding Air Con Hose Fittings A Comprehensive Guide

Air conditioning systems are essential for maintaining comfortable temperatures in vehicles and buildings, particularly during the sweltering heat of summer. A crucial component of these systems is the air con hose fittings. In this article, we will delve into the various types of air conditioning hose fittings, their applications, and tips for maintenance and replacement.

What Are Air Con Hose Fittings?

Air con hose fittings are specialized components used to connect various parts of an air conditioning system. These fittings link the hose to the compressor, condenser, evaporator, and other critical components. Properly functioning fittings ensure optimal performance of the entire air conditioning system, facilitating efficient refrigerant flow and maintaining cooling efficiency.

Types of Air Con Hose Fittings

1. Threaded Fittings These are perhaps the most common type of fittings used in air conditioning systems. Threaded fittings are designed to screw onto the hoses and other fittings, providing a secure and leak-proof connection. The threads can be tapered or straight, with various sizes available to accommodate different hose diameters.

2. Barbed Fittings Barbed fittings have raised ridges that create friction to hold the hose in place. These fittings are easy to install and are often used in lower-pressure applications. The ridged design makes them less likely to slip off than smooth fittings, which is essential for maintaining system pressure.

3. Flared Fittings Flared fittings involve flaring the end of the hose and connecting it to a corresponding flared fitting. This type of connection provides a very secure seal, making it suitable for high-pressure refrigerant applications. Flared fittings are often found in the connection between the compressor and the condenser.

4. Quick Connect Fittings Quick connect fittings are designed for easy installation and removal. They allow technicians to quickly disconnect hoses without the need for tools, making them a popular choice in automotive applications. These fittings are especially useful for routine maintenance and repairs.

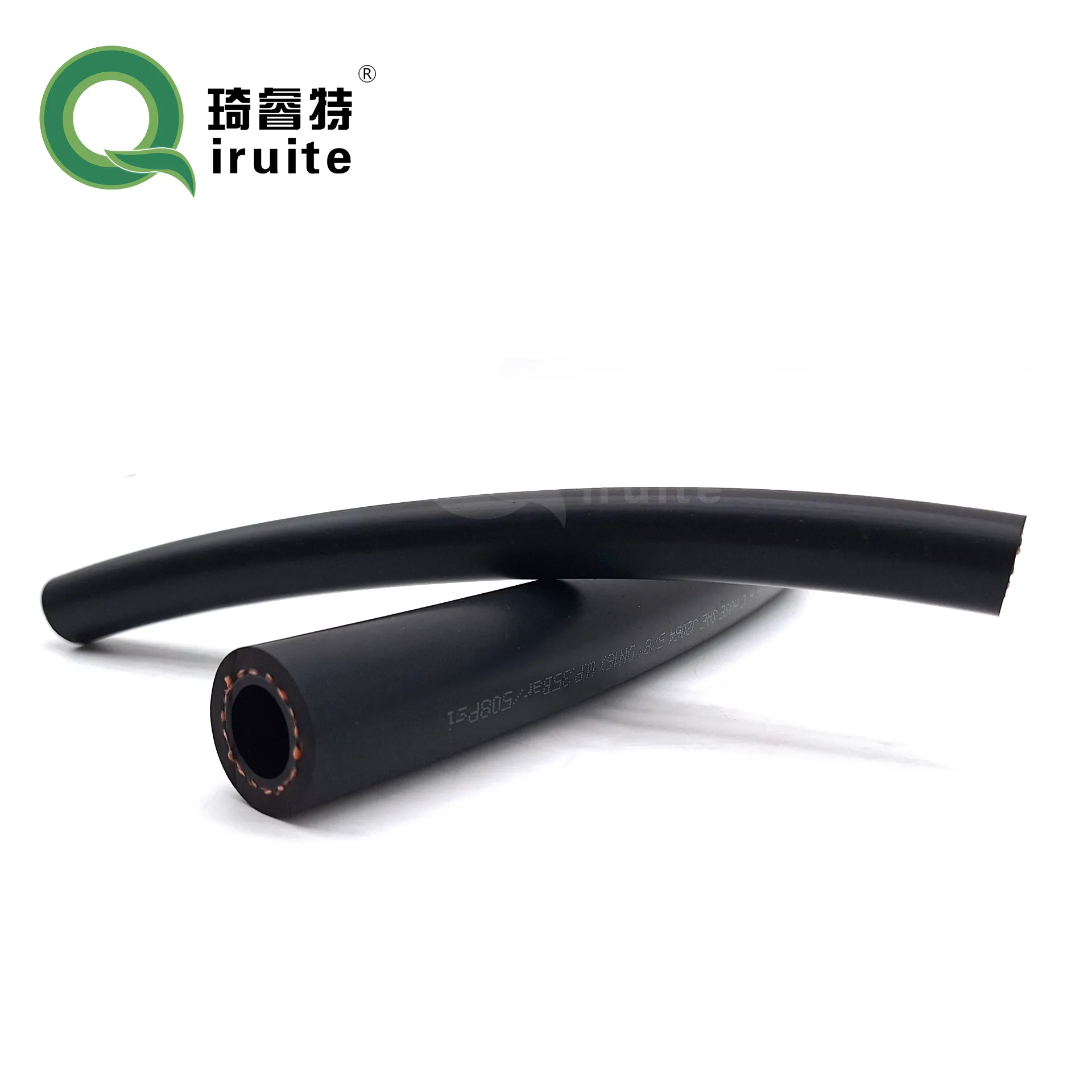

air con hose fittings

5. Compression Fittings Compression fittings use a compression mechanism to create a seal between the hose and the fitting. They are often used in situations where a secure connection is crucial, and they are typically more forgiving of minor misalignments than threaded fittings.

Maintenance and Replacement Tips

Maintaining air con hose fittings is vital for the longevity and efficiency of your air conditioning system. Here are some tips

- Regular Inspections Check fittings for signs of wear, such as cracks, corrosion, or leaks. Regularly inspecting your air conditioning system can help detect issues before they become significant problems.

- Use the Correct Type of Fitting Ensure that the fittings you choose are compatible with your specific air conditioning system and refrigerant type. Using the wrong type of fitting can lead to leaks and decreased performance.

- Proper Installation When installing new fittings, ensure they are properly tightened but not overtightened, as this can damage the threads or the hose itself.

- Replacement is Key If you discover any compromised fittings, replace them promptly. It's best to use high-quality fittings to ensure reliability and performance.

Conclusion

Air con hose fittings play a vital role in the functionality and efficiency of air conditioning systems. Understanding the different types of fittings and how to maintain them can extend the life of your system and improve its performance. Whether in an automotive context or in residential and commercial HVAC systems, proper attention to these components will not only guarantee cooler air but also more efficient energy use, ultimately saving you money and enhancing comfort.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025