air brake hose fitting

Understanding Air Brake Hose Fittings Importance and Maintenance

Air brake systems are essential for safe and efficient operation in heavy-duty vehicles, such as trucks and buses. One of the critical components of these systems is the air brake hose fitting. This small, often overlooked piece plays a significant role in ensuring that the entire braking system functions correctly and safely.

What is an Air Brake Hose Fitting?

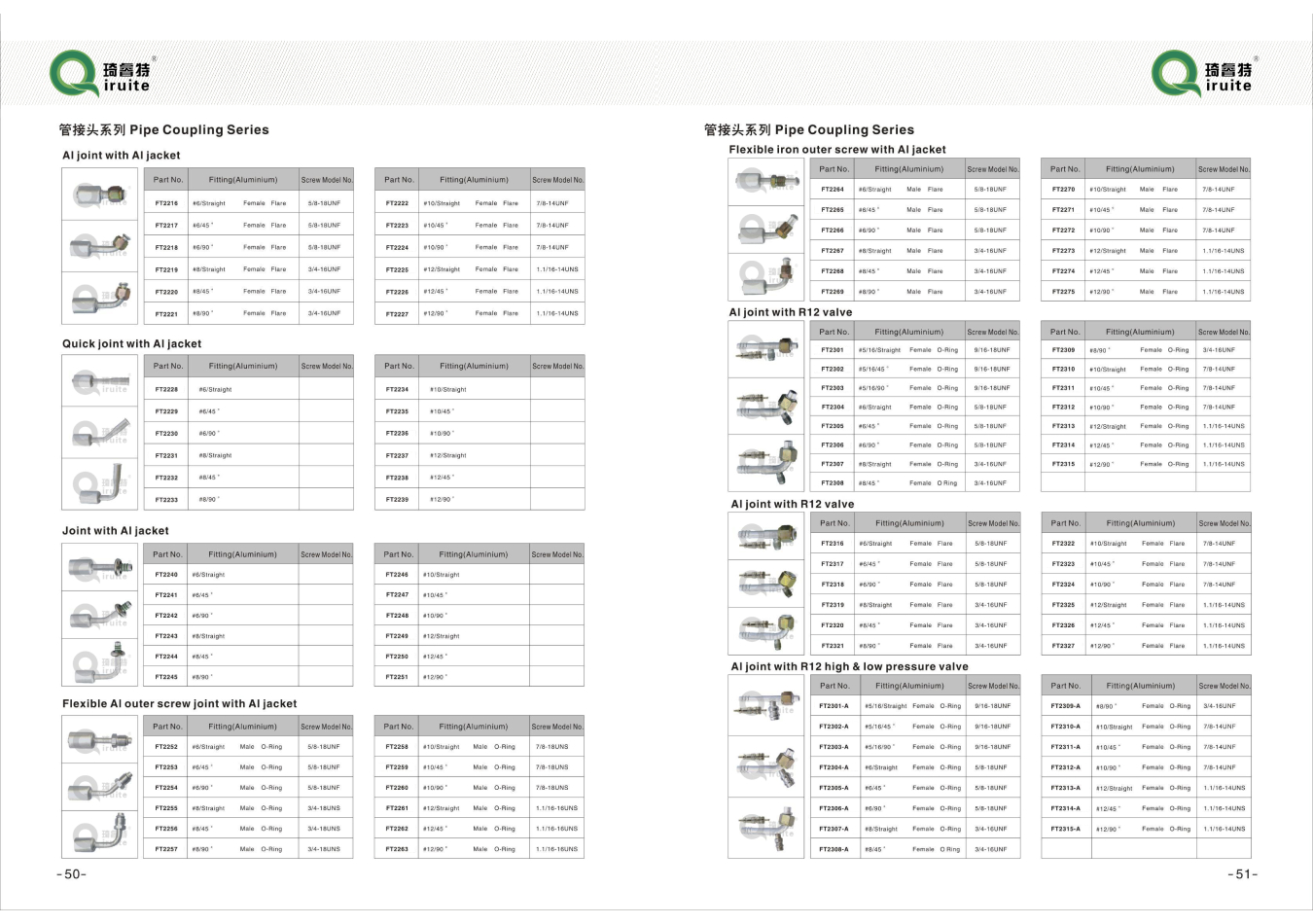

An air brake hose fitting is a connector that joins the air brake hoses to various components in the air brake system, including compressors, valves, and the brake chambers themselves. These fittings come in various sizes and types to accommodate different vehicle designs and braking requirements. Common materials used for these fittings include brass, steel, and aluminum, each selected for its durability and resistance to environmental factors.

Importance of Air Brake Hose Fittings

The air brake system relies on compressed air to activate the brakes. When the driver presses the brake pedal, air is released from the storage tanks, traveling through the hoses and into the brake chambers, which in turn apply the brakes. Therefore, the integrity of every connection is crucial. Any wear, tear, or leak in the air brake hose fittings can lead to a system failure, causing catastrophic results. A malfunctioning air brake system can result in extended stopping distances, loss of brake pressure, or even total brake failure.

air brake hose fitting

Signs of Wear and Important Maintenance Tips

Regular maintenance of air brake hose fittings is necessary to ensure safety and reliability. Operators should look for signs of wear or potential issues, including

1. Visual Inspection Regularly check the fittings for any signs of corrosion, cracking, or deformation. 2. Air Leaks Listen for hissing sounds, which may indicate air leaks in the fittings. 3. Pressure Testing Conduct routine pressure tests to assess the effectiveness of the fittings. 4. Replacement If any fitting exhibits wear or damage, it should be replaced immediately to ensure the integrity of the braking system.

In addition to the fittings themselves, the hoses should also be inspected for any signs of wear. Cracks, abrasions, or bulges in the hoses can compromise the entire brake system. The recommended practice is to replace hoses every three to five years, depending on the vehicle's usage and operating conditions.

Conclusion

Air brake hose fittings might seem like minor components in the broader air brake system, but their impact on vehicle safety cannot be overstated. Ensuring their functionality through regular maintenance and inspections is critical for the safe operation of heavy-duty vehicles. Drivers and fleet operators must prioritize the integrity of these fittings as part of their overall maintenance routine, ensuring the safety of all road users. Keeping an eye on these crucial components can prevent potential accidents and enhance the reliability of the vehicle's braking performance. Thus, investing time in understanding and maintaining air brake hose fittings is essential for anyone operating heavy vehicles.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025