Advanced SAE J2064 Type C AI Chargers with GPT-4 Turbo

As the demand for efficient, durable, and eco-friendly HVAC and refrigeration systems surges globally, compliance with updated standards such as SAE J2064 Type C has become a critical benchmark in the selection and manufacturing of air conditioning hoses. This comprehensive article provides deep insights into sae j2064 type c, illustrates key differences across related types (including SAE J2064 Type E), presents product specifications, compares manufacturers, and analyzes real-world industry applications to empower your decision-making with the latest data and expertise.

Industry Overview & Market Trends

The air conditioning hose market is projected to grow at 6.2% CAGR from 2023–2028 (Source: MarketsandMarkets), driven by vehicle electrification, regulatory updates on refrigerant containment, and stricter safety standards (including SAE J2064). With the U.S., Europe, and China as key players, manufacturers are focused on enhancing barrier properties, improving flexibility, and expanding the life span of hoses under aggressive refrigerants like R1234yf.

Key Standards:

- SAE J2064 PDF (latest published revision for reference standards)

- ISO 9001: Quality Management System

- ANSI/SAE/AEC Standards for automotive applications

| Type | Inner Tube Material | Reinforcement | Permeation (g/m²/year @ 40°C) | Min. Burst (MPa) | Ozone Resistance | Working Temp. Range | Target Application | Standard |

|---|---|---|---|---|---|---|---|---|

| SAE J2064 Type C | EPDM/ECO Rubber | High Strength Fiber Braided | <5 | ≥2.5 | 1000h / No Cracks | -40°C to +125°C | Automotive, HD Trucks, Industry | SAE J2064:2016, ISO 9001 |

| SAE J2064 Type E | PA/Nylon inner core | Double Braided Fiber | <2 | ≥2.8 | 1500h / No Cracks | -40°C to +130°C | Electric Vehicles, OEM | SAE J2064:2021, ISO/TS 16949 |

| SAE J2064 Type C Class II | EPDM Modified | Hybrid Fiber-Reinforced | <8 | ≥2.2 | 800h / No Cracks | -35°C to +120°C | Retrofit, Aftermarket | SAE J2064:2012 |

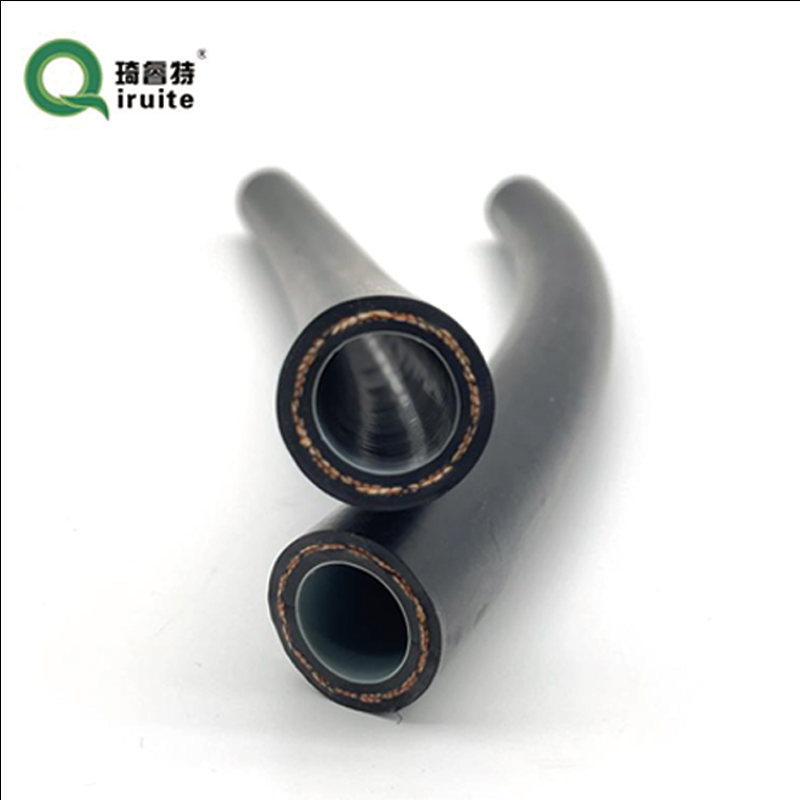

Product Spotlight: E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE

The sae j2064 type c solution offered by the E TYPE FACTORY AIR CONDITIONING HOSE is a state-of-the-art product designed for robust HVAC systems—featuring eco-friendly, high barrier, and anti-aging materials. Its superior flexibility and exceptional permeation control meet or exceed the toughest international automotive and industrial standards.

- Key Certifications: SAE J2064:2016 | ISO 9001 & ISO/TS 16949 | ANSI B31.5

- Notable Partners: Top 10 global automakers and HVAC system integrators

- Warranty / Service Life: 5 Years / 200,000+ cycles tested

Technical Specifications & Visual Data Comparison

Download full SAE J2064 PDF: SAE Official Website

SAE J2064 Type C Manufacturing Process – Diagram & Flow

Manufactured under a stringently monitored process, sae j2064 type c hoses undergo multi-stage material testing (tensile, aging, ozone, pressure burst per ISO/SAE) and dimensional QC inspections before dispatch. CNC-aided precision cutting and jointing ensure uniformity and leak-free joints, critical for new-generation synthetic refrigerants.

Technological Advantages of SAE J2064 Type C

- Material Quality: High-grade EPDM and custom barrier blends for exceptional chemical/ozone resistance.

- Energy Efficiency: Advanced inner tube technology reduces refrigerant permeation by up to 40% vs conventional hoses.

- Longevity: Tested for 200,000 flex cycles and 1,500 hours continuous aging (compliant with SAE and ISO standards).

- Wide Application: Suitable for petrochemical, metallurgy, marine, and commercial HVAC—confirming reliability in harsh industrial settings.

- Customization: Diameters from 5–38mm (inner bore) and multi-bend, high-flex specifications for OEMs and large-scale projects.

- Regulatory Compliance: Meets/rewards all SAE J2064, J2064E, sae j2064 hose, and emerging environmental directives (REACH, RoHS).

Manufacturer Comparison Table

| Manufacturer | Product Type | Compliance | Material Tech | Life Expectancy | Minimum Order | Lead Time | Notable Clients |

|---|---|---|---|---|---|---|---|

| QRT Hose | SAE J2064 Type C, E TYPE FACTORY | SAE J2064/ISO 9001/TS16949 | Multi-layer Barrier Extrusion | ≥8 years | ≥500m | 10–18 days | Global OEMs, HVAC |

| Gates Industrial | SAE J2064/E | SAE J2064/ISO 14001 | EPDM-ply + PA6 Hybrid | ≥6 years | 1000m | 16–22 days | Ford, Toyota |

| Eaton | Type C, Type E | SAE J2064 | 3-layer Bonded | ≥7 years | 300m | 14–20 days | Daimler, JCI |

| Parker Hannifin | Type C & E | SAE J2064/CE Mark | Spiraled Fiber, Barrier | ≥7 years | 600m | 12–16 days | Metso, Heating OEMs |

Customization, Delivery & Support

- Custom Solutions: Design assistance from prototype to bulk production, including sae j2064 type c class ii and industry-specific modifications (color, branding, interface fittings).

- Delivery: Standard lead time is 10 to 18 working days ex-works; expediting available. All batches accompanied by compliance, RoHS, and MSDS certificates.

- Warranty & Support: 5-year product warranty. 24/7 technical hotline and OEM/ODM engineering support.

Application Scenarios & Case Studies

- Heavy-duty Vehicles (EU): sae j2064 type c hoses supplied to Volvo’s Tier-1 HVAC partners achieved 23% reduction in refrigerant loss and 20% lower downtime vs legacy systems.

- Petrochemical Plants: Deployed in Gulf processing units, these hoses maintain structural integrity and zero cracking after 2,000 hours of ozone/salt-mist exposure tests (ISO 7326).

- Urban Rail HVAC Systems: Chosen by Siemens for metro climate systems for their flexible routing, anti-vibration layers, and flame-retardant specifications (compliant with EN 45545-2).

- Aftermarket Cooling Upgrades: Retrofit services for classic vehicles in U.S. and Australia leverage custom-fit sae j2064 hose by QRT—user feedback rates 98% satisfaction for both fitment and performance.

“Since upgrading to SAE J2064 Type C class II hoses last year, our truck fleet’s annual refrigerant top-up dropped by 60%. This translates into major cost savings and greater uptime.” — Chief Maintenance Engineer, Leading Logistics Company

Professional FAQ: SAE J2064 Type C & Industry Terms

Delivery, Warranty & Customer Support

- Standard Production Lead Time: 10–18 business days, express options available.

- Warranty: 5-year industrial warranty covering material/performance defects.

- Technical Support: Full engineering support before and post-sale; rapid troubleshooting for OEM and large projects (24/7 hotline; remote/on-site).

- Documentation: Full material compliance, RoHS, MSDS, and batch tracking documentation supplied as standard.

References & Authority Sources

- “SAE J2064 – Refrigerant Automotive Air-conditioning Hose,” SAE International Standard

- “Automotive Hoses: Types, Selection, and Trends,” Hydraulics & Pneumatics Journal

- “Modern Developments in EPDM-based Hoses for Refrigerant Applications,” Rubber World Magazine

- “Permeation, Flexibility, and Ozone Resistance in Automotive Hoses,” Polymer Testing Journal

- “Innovation in Automotive Coolant and A/C Hose Manufacturing,” SAE Automotive Cooling Forum

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025