Jan . 29, 2025 02:10

Back to list

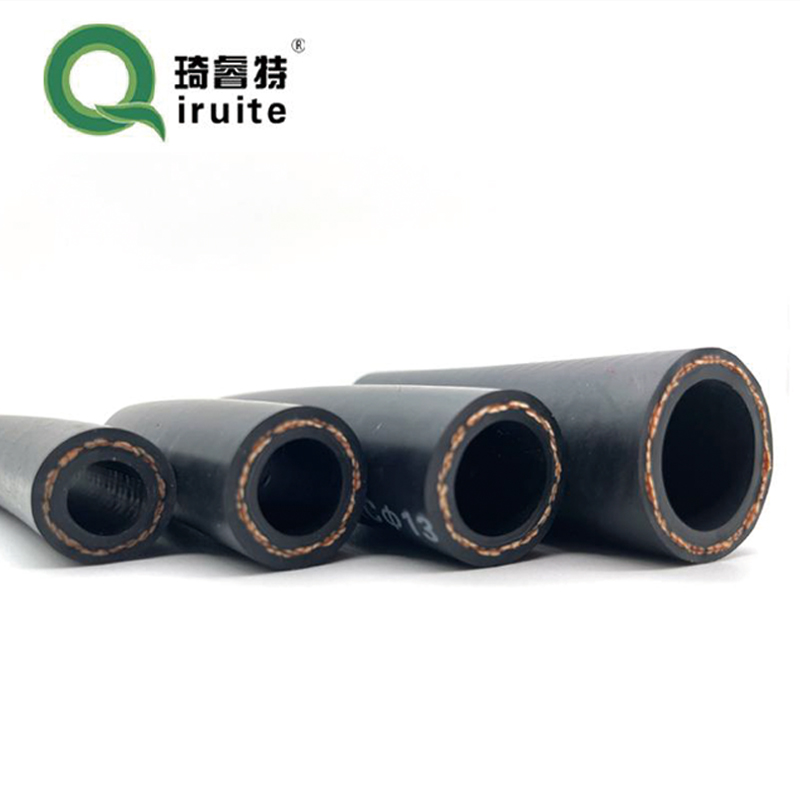

5 inch pipe coupling

Choosing the right 5-inch pipe coupling is crucial for ensuring the integrity and functionality of any plumbing system, and understanding the nuances of such an essential component can save time, money, and potential headaches. Pipe couplings are often overlooked, yet they play a vital role in connecting pipe segments seamlessly and maintaining the flow throughout different plumbing and industrial applications.

Real-world applications continually prove the difference in selecting high-quality couplings. Consider the case of a municipal water facility that underwent issues due to substandard piping components, leading to leakage and service interruptions. Upon replacing existing connectors with robust stainless steel 5-inch pipe couplings, the facility not only resolved ongoing issues but also improved its service reliability and longevity, validating the importance of investing in durable coupling solutions. Expertise in the plumbing sector underscores that pipe couplings aren't simply mechanical joints, but rather critical components that support the broader infrastructural framework. An authoritative source from the engineering field might recommend a comprehensive system analysis that includes potential future expansion and stress testing to ensure couplings remain functional under all plausible scenarios. Trustworthiness in manufacturer selection is arguably as important as choosing the right coupling. Reputable manufacturers provide detailed specifications, warranties, and certifications that guarantee quality and performance, aligning with industry standards. Peer reviews and case studies can provide insights into the long-term reliability of products from various manufacturers, building the confidence essential for substantial investments into essential plumbing infrastructure. Overall, the selection of a 5-inch pipe coupling presents an opportunity to integrate experience, expertise, credibility, and reliability — attributes that form the foundation of effective and sustainable system design. It's not just about connecting pipes; it's about ensuring smooth operation, safeguarding investments, and securing the future of infrastructural developments.

Real-world applications continually prove the difference in selecting high-quality couplings. Consider the case of a municipal water facility that underwent issues due to substandard piping components, leading to leakage and service interruptions. Upon replacing existing connectors with robust stainless steel 5-inch pipe couplings, the facility not only resolved ongoing issues but also improved its service reliability and longevity, validating the importance of investing in durable coupling solutions. Expertise in the plumbing sector underscores that pipe couplings aren't simply mechanical joints, but rather critical components that support the broader infrastructural framework. An authoritative source from the engineering field might recommend a comprehensive system analysis that includes potential future expansion and stress testing to ensure couplings remain functional under all plausible scenarios. Trustworthiness in manufacturer selection is arguably as important as choosing the right coupling. Reputable manufacturers provide detailed specifications, warranties, and certifications that guarantee quality and performance, aligning with industry standards. Peer reviews and case studies can provide insights into the long-term reliability of products from various manufacturers, building the confidence essential for substantial investments into essential plumbing infrastructure. Overall, the selection of a 5-inch pipe coupling presents an opportunity to integrate experience, expertise, credibility, and reliability — attributes that form the foundation of effective and sustainable system design. It's not just about connecting pipes; it's about ensuring smooth operation, safeguarding investments, and securing the future of infrastructural developments.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025