Feb . 05, 2025 01:38

Back to list

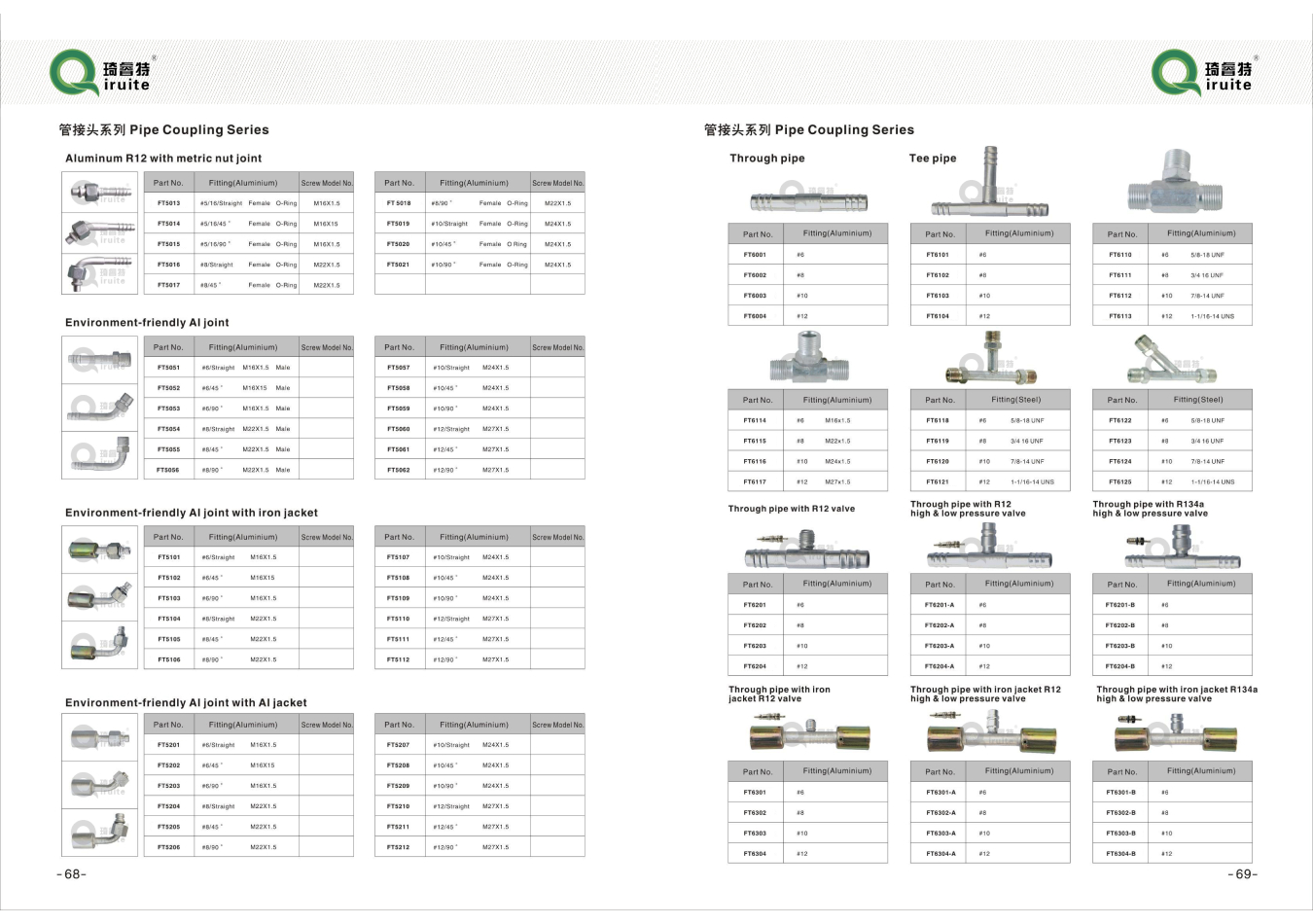

5 8 pipe coupling

Understanding the nuances of pipe couplings can dramatically enhance the efficiency and safety of piping systems, particularly in the face of diverse industrial applications. The 5 8 pipe coupling, with its distinct specifications, addresses a range of utility needs across various sectors, making it indispensable for experts in engineering and plumbing.

On the trustworthiness front, the 5 8 pipe coupling's reputation is cemented through rigorous testing and real-world validation. Manufacturers typically provide substantial documentation on quality control processes, such as hydrostatic pressure testing or fatigue analysis, to ensure reliability over time. Certifications from recognized bodies affirm that these couplings adhere to stringent quality benchmarks, instilling confidence in both procurement specialists and operational technicians. Moreover, industry-specific adaptations may involve creative solutions tailored to meet unique requirements, whether they are related to extreme environmental conditions, diverse fluid compositions, or specific mechanical constraints. Collaboration with experts who bring their wealth of knowledge in metallurgy, materials science, and engineering design is invaluable for leveraging the full potential of the 5 8 coupling in specialized applications, such as oil and gas extraction or high-speed conveyance systems. The integration of modern technology, like real-time monitoring sensors or adaptive feedback systems, further enhances the reliability and functionality of these pipe couplings. By collecting and analyzing data, operators can preemptively address wear-and-tear issues before they escalate into costly failures. This proactive maintenance approach extends the lifespan of infrastructure and optimizes the resource allocation for repairs and replacements. The strategic application of 5 8 pipe couplings can considerably elevate operational standards across various industry sectors. This coupling offers not only physical connectivity but also a systematic enhancement to fluid mechanics within piping frameworks, cementing its role as a vital component for ensuring operational excellence. Its proven track record and continuous improvements through advances in material engineering and design innovation sustain its relevance in an ever-evolving industrial landscape. In summary, the 5 8 pipe coupling stands as a paragon of excellence in pipe joint technology, enabling seamless operation across different sectors. Its proven resilience, supported by rigorous research and development, renders it an indispensable asset for engineers striving for efficiency, safety, and durability in piping systems nationwide.

On the trustworthiness front, the 5 8 pipe coupling's reputation is cemented through rigorous testing and real-world validation. Manufacturers typically provide substantial documentation on quality control processes, such as hydrostatic pressure testing or fatigue analysis, to ensure reliability over time. Certifications from recognized bodies affirm that these couplings adhere to stringent quality benchmarks, instilling confidence in both procurement specialists and operational technicians. Moreover, industry-specific adaptations may involve creative solutions tailored to meet unique requirements, whether they are related to extreme environmental conditions, diverse fluid compositions, or specific mechanical constraints. Collaboration with experts who bring their wealth of knowledge in metallurgy, materials science, and engineering design is invaluable for leveraging the full potential of the 5 8 coupling in specialized applications, such as oil and gas extraction or high-speed conveyance systems. The integration of modern technology, like real-time monitoring sensors or adaptive feedback systems, further enhances the reliability and functionality of these pipe couplings. By collecting and analyzing data, operators can preemptively address wear-and-tear issues before they escalate into costly failures. This proactive maintenance approach extends the lifespan of infrastructure and optimizes the resource allocation for repairs and replacements. The strategic application of 5 8 pipe couplings can considerably elevate operational standards across various industry sectors. This coupling offers not only physical connectivity but also a systematic enhancement to fluid mechanics within piping frameworks, cementing its role as a vital component for ensuring operational excellence. Its proven track record and continuous improvements through advances in material engineering and design innovation sustain its relevance in an ever-evolving industrial landscape. In summary, the 5 8 pipe coupling stands as a paragon of excellence in pipe joint technology, enabling seamless operation across different sectors. Its proven resilience, supported by rigorous research and development, renders it an indispensable asset for engineers striving for efficiency, safety, and durability in piping systems nationwide.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025