3 pipe coupling

The Versatility of 3% Pipe Couplings in Modern Applications

In the realm of plumbing, construction, and various industrial sectors, the significance of reliable and efficient pipe coupling solutions cannot be overstated. The term ‘3% pipe coupling’ may not seem familiar at first glance, but it pertains to a specific type of coupling that is gaining traction in modern applications. This article explores the characteristics, benefits, and various applications of 3% pipe couplings.

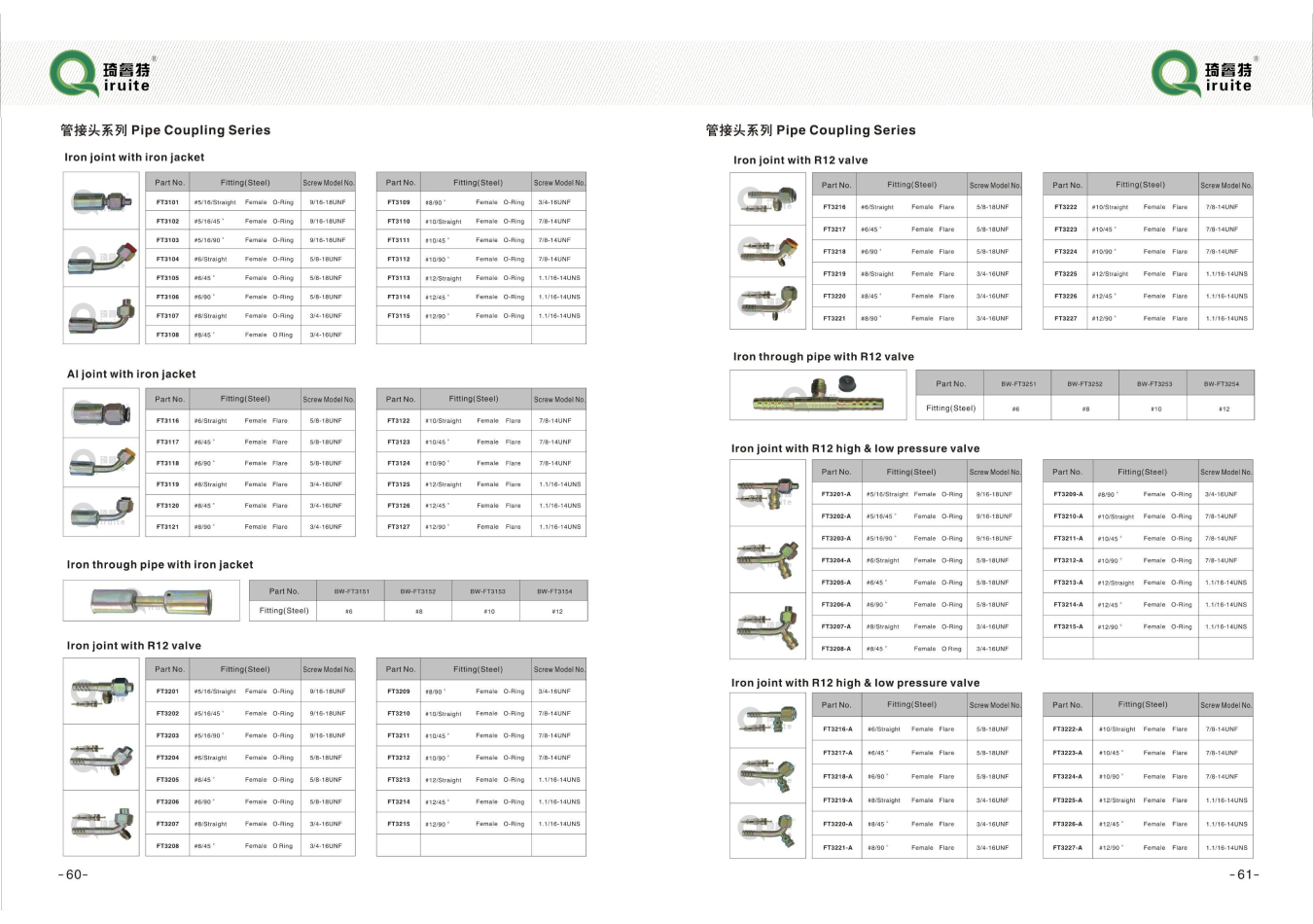

To begin with, it’s essential to understand what pipe couplings are. In simple terms, pipe couplings are fittings that connect two lengths of pipe. They play a crucial role in ensuring that pipes remain secure and leak-free. Various types of couplings include threaded, soldered, and flanged options, but 3% pipe couplings present a unique advantage for particular applications.

The Versatility of 3% Pipe Couplings in Modern Applications

One of the primary benefits of 3% pipe couplings is their resistance to corrosion. Traditional metal couplings can deteriorate over time due to environmental factors, leading to leaks, reduction in flow efficiency, and in severe cases, system failures. However, 3% couplings are often coated or made from materials that exhibit excellent resistance to corrosive elements, ultimately extending their lifespan and reliability in various environments, particularly in water and wastewater systems.

3 pipe coupling

Another significant advantage is the ease of installation. 3% pipe couplings are typically designed for user-friendly assembly, enabling quicker connections and reducing labor costs. This is particularly beneficial in large-scale projects where time efficiency is critical. The lightweight nature of these couplings also simplifies transportation and handling, making them an ideal choice for remote or difficult-to-access locations.

Additionally, 3% pipe couplings contribute to energy efficiency. By minimizing the weight of the piping system, these couplings reduce the overall energy consumption associated with transportation and installation. In industries such as oil and gas, where pipe systems can span vast distances, the cumulative savings in energy and material can be substantial, making 3% couplings not only an economical choice but also an environmentally friendly one.

In terms of applications, 3% pipe couplings find their roles in diverse fields ranging from residential plumbing to heavy industrial settings. They are increasingly being used in HVAC systems, where proper fittings are essential for maintaining airflow and efficiency. Moreover, in water treatment facilities, ensuring a leak-free system is paramount, and the reliability offered by 3% couplings makes them a staple in these infrastructures.

In summary, 3% pipe couplings represent a significant step forward in pipe fitting technology. Their corrosion resistance, ease of installation, lightweight nature, and contribution to energy efficiency make them an attractive option for various industries. As we continue to seek more sustainable and efficient solutions in construction and engineering, the versatility and benefits of 3% pipe couplings will undoubtedly play a pivotal role in shaping future infrastructure projects. By embracing these advancements, professionals in the field can ensure enhanced performance, reduced costs, and increased longevity in their piping systems, ultimately leading to greater overall success in their endeavors.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025