3 4 steel coupling

The Significance of 3% 204% Steel Coupling in Modern Engineering

In the realm of engineering and manufacturing, the choice of materials is paramount for the success of any project. Among the various materials available, steel plays a pivotal role due to its exceptional strength, durability, and versatility. One particular formulation that has garnered attention is the 3% 204% steel coupling, a specific type of stainless steel that offers unique characteristics suitable for various industrial applications.

Understanding 3% 204% Steel Coupling

The designation 3% 204% refers to the chemical composition of this alloy, primarily distinguishing it from other steel types. In this case, the core composition includes around 3% nickel and a certain percentage of chromium, contributing significantly to the corrosion resistance and mechanical properties of the material. This alloy, which falls under the category of austenitic stainless steels, is renowned for its excellent oxidation resistance and high strength at both ambient and elevated temperatures.

A significant advantage of 3% 204% steel is its ability to withstand harsh environments. Industries such as chemical processing, oil and gas, and food production often expose materials to corrosive substances. The inherent properties of this steel coupling allow it to perform reliably under such conditions, which is critical for ensuring safety and functionality in industrial operations.

Applications of 3% 204% Steel Coupling

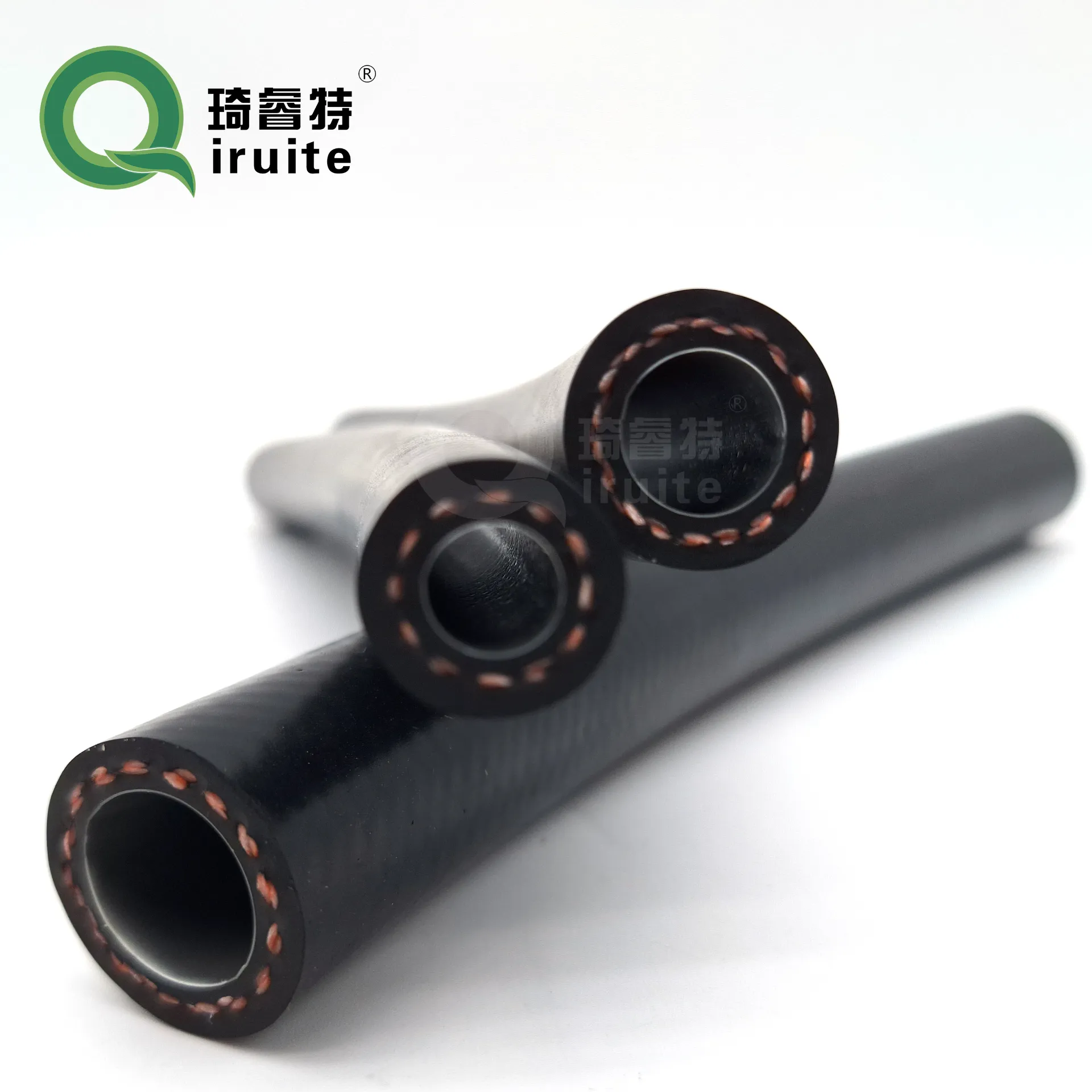

The applications of 3% 204% steel coupling are diverse and span multiple sectors. One of the most common uses is in the manufacturing of pipe fittings and couplings. These fittings are essential for connecting pipes in various large-scale installations, such as water treatment plants, petrochemical facilities, and HVAC systems. The durability of 3% 204% steel ensures that connections remain intact under pressure, reducing the risk of leaks and system failures.

3 4 steel coupling

Another significant application is in fasteners and hardware components. Bolts, nuts, and screws made from this steel benefit from its strength and corrosion resistance, making them ideal for use in marine environments and outdoor structures. The longevity of the fasteners contributes to lower maintenance costs and increased safety for constructions and machinery.

Also, in the automotive industry, 3% 204% steel coupling is utilized in various components that require high strength and low weight. This material’s properties enable manufacturers to create lightweight designs without compromising on durability, which enhances fuel efficiency and performance.

Advantages Over Other Materials

When compared to other materials, such as carbon steel or lower-grade stainless steels, 3% 204% steel coupling presents several advantages. Firstly, its resistance to rust and corrosion significantly outperforms that of carbon steel, making it a superior choice for applications where exposure to moisture and corrosive substances is inevitable. This property not only extends the life of the components but also reduces the need for frequent replacements, which can save time and resources.

Secondly, the mechanical properties of 3% 204% steel enable it to withstand higher stresses and loads. This quality is particularly advantageous in construction and industrial settings, where the failure of any component can lead to catastrophic results.

Conclusion

In conclusion, 3% 204% steel coupling represents a cornerstone of modern engineering materials, offering exceptional strength, durability, and corrosion resistance. Its versatility across various applications—from piping systems and automotive components to fasteners—shows its importance in maintaining efficiency and safety in industrial practices. As industries continue to evolve and demand more from their materials, the role of high-performance alloys like 3% 204% steel will undoubtedly grow, solidifying its place in the future of engineering innovation. Whether in challenging environments or critical structural applications, the benefits of this specific steel coupling exemplify the necessary advancements that contribute to the efficiency and safety of modern infrastructure. Companies that wisely invest in such reliable materials will likely reap the benefits of longevity and performance in their projects, ultimately driving success in a competitive market.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025