Jan . 26, 2025 00:38

Back to list

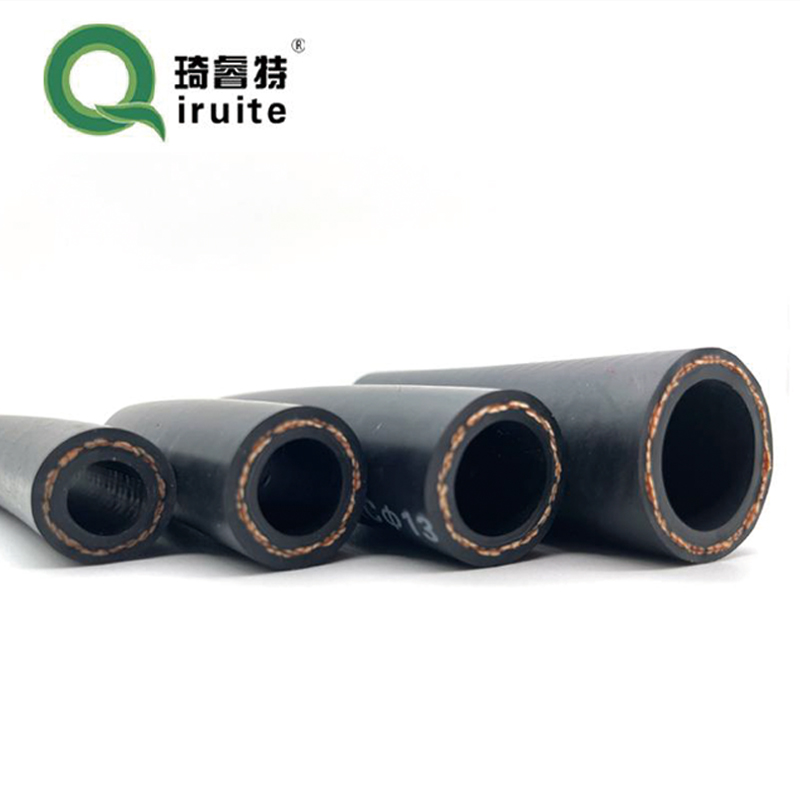

Spiral Protection

When it comes to selecting components in industrial applications, especially those involving fluid transport, finding reliable pipe couplings is crucial. Among the various options available, 2 pipe couplings stand out for their versatility and dependable performance. These couplings serve as fundamental connectors in piping systems, ensuring safety, efficiency, and functionality in diverse environments. The relevance of 2 pipe couplings in various sectors cannot be understated, especially given their crucial role in both residential and commercial settings.

Authoritative guidelines suggest that regular maintenance and timely upgrades of piping systems are integral to prolonging the lifespan of the infrastructure and preventing hazardous failures. 2 pipe couplings are endorsed by industry standards due to their reliability and conformity with safety regulations. In sectors such as oil and gas, pharmaceuticals, and food processing, where exposure to corrosive substances or extreme conditions is common, these couplings are often considered indispensable. Their presence ensures that pipes remain securely attached, thus preventing spills, leaks, and potential system collapses. The trustworthiness of 2 pipe couplings is further cemented by empirical evidence from rigorous testing and certification in labs that meet international standards. Such evaluations affirm the couplings’ capability to endure stress tests that simulate real-world scenarios. This testing is crucial, as it provides certainty that the couplings can perform in high-risk environments without failure. Engineers and decision-makers can rely on these certifications when specifying components for critical applications, knowing that the selected fittings are proven to uphold the system's safety and performance requirements. Moreover, using data-driven strategies, manufacturers are continuously improving the designs of 2 pipe couplings to align with technological advances and today’s environmental considerations. Innovations like eco-friendly materials and advanced sealing technologies are being integrated to enhance performance while minimizing ecological impact. Such improvements not only increase the competitiveness of these products in the market but also assure consumers of their commitment to sustainability and efficiency. In conclusion, 2 pipe couplings are more than mere connectors in a piping system. They represent a combination of practical engineering, material science, and compliance with stringent safety norms. Their role in ensuring system integrity, preventing environmental hazards, and optimizing operational efficiency underscores their growing importance across industries. As technology progresses, 2 pipe couplings will likely continue to evolve, incorporating new materials and design philosophies to meet the ever-changing demands of global industrial and residential needs. Investing in high-quality, certified 2 pipe couplings is a prudent choice for any infrastructure project, offering peace of mind and assurance of system reliability.

Authoritative guidelines suggest that regular maintenance and timely upgrades of piping systems are integral to prolonging the lifespan of the infrastructure and preventing hazardous failures. 2 pipe couplings are endorsed by industry standards due to their reliability and conformity with safety regulations. In sectors such as oil and gas, pharmaceuticals, and food processing, where exposure to corrosive substances or extreme conditions is common, these couplings are often considered indispensable. Their presence ensures that pipes remain securely attached, thus preventing spills, leaks, and potential system collapses. The trustworthiness of 2 pipe couplings is further cemented by empirical evidence from rigorous testing and certification in labs that meet international standards. Such evaluations affirm the couplings’ capability to endure stress tests that simulate real-world scenarios. This testing is crucial, as it provides certainty that the couplings can perform in high-risk environments without failure. Engineers and decision-makers can rely on these certifications when specifying components for critical applications, knowing that the selected fittings are proven to uphold the system's safety and performance requirements. Moreover, using data-driven strategies, manufacturers are continuously improving the designs of 2 pipe couplings to align with technological advances and today’s environmental considerations. Innovations like eco-friendly materials and advanced sealing technologies are being integrated to enhance performance while minimizing ecological impact. Such improvements not only increase the competitiveness of these products in the market but also assure consumers of their commitment to sustainability and efficiency. In conclusion, 2 pipe couplings are more than mere connectors in a piping system. They represent a combination of practical engineering, material science, and compliance with stringent safety norms. Their role in ensuring system integrity, preventing environmental hazards, and optimizing operational efficiency underscores their growing importance across industries. As technology progresses, 2 pipe couplings will likely continue to evolve, incorporating new materials and design philosophies to meet the ever-changing demands of global industrial and residential needs. Investing in high-quality, certified 2 pipe couplings is a prudent choice for any infrastructure project, offering peace of mind and assurance of system reliability.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025