Feb . 01, 2025 00:48

Back to list

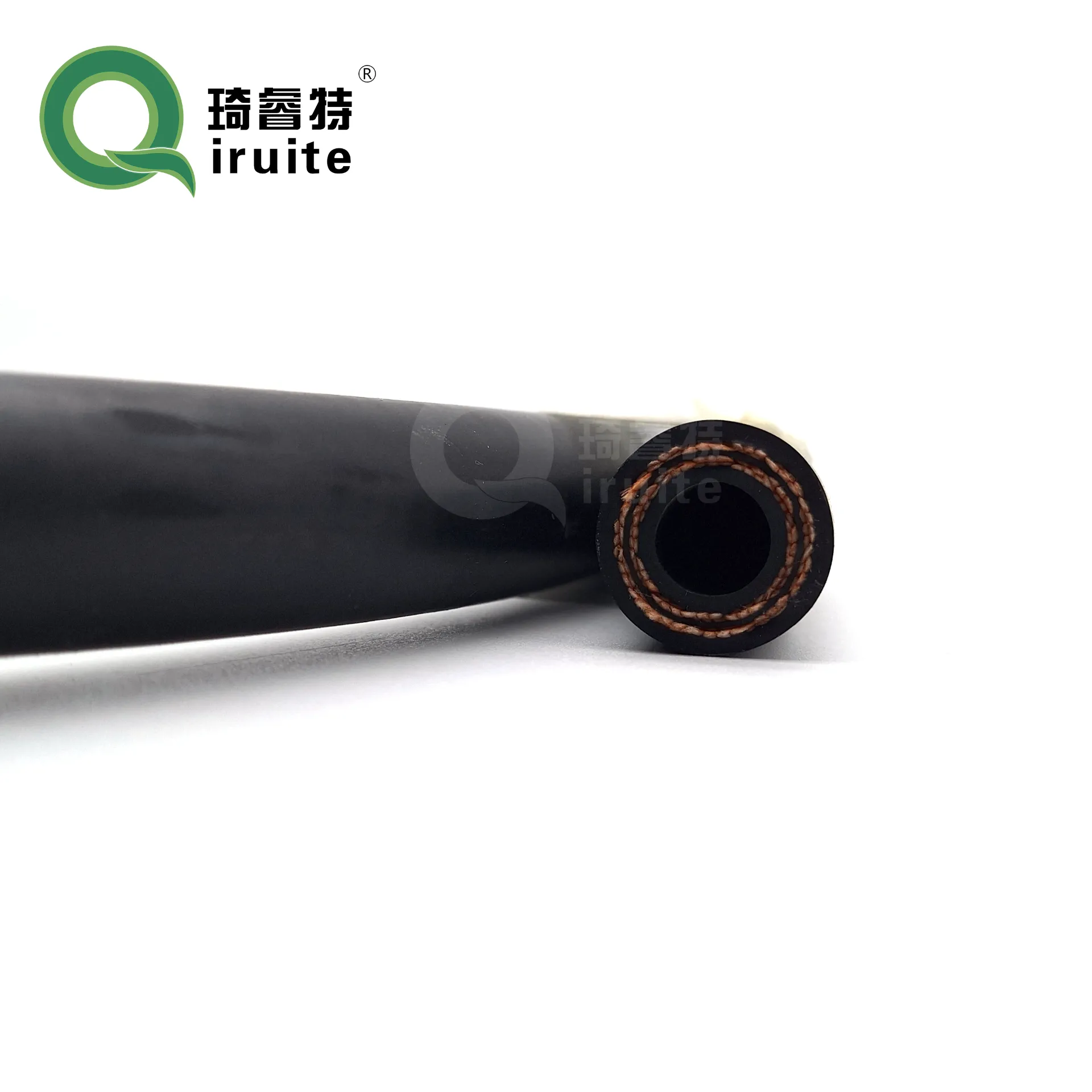

150mm coupling

In the world of plumbing and construction, precision and reliability are crucial. One such indispensable tool that embodies these qualities is the 150mm coupling. While it might seem like a simple component, its significance across various industries cannot be understated.

When it comes to trustworthiness, the 150mm coupling's track record speaks volumes. Countless case studies and user reviews laud its reliability. Companies that depend on consistent and uninterrupted operations cannot afford failure in their systems, and it's this coupling that often provides them with peace of mind. Its trusted performance is a testament to quality manufacturing processes and thorough quality control measures implemented by reputable producers. In practical terms, the installation of a 150mm coupling should never be underestimated. The process demands precision to ensure that the tight fit prevents leaks and maintains system integrity. It’s not just a matter of matching dimensions; an experienced technician knows that proper alignment and torque application are crucial. These meticulous installation details underscore the necessity of trained professionals who understand the nuances of the coupling’s application. Additionally, constant innovation in design and materials promises an even brighter future for the 150mm coupling. As industries evolve and new challenges arise, manufacturers are investing in research and development to optimize couplings for better performance, longer lifespans, and enhanced environmental compatibility. It's not far-fetched to anticipate smart technology integration in these components, which could revolutionize system maintenance and diagnostics. In conclusion, the 150mm coupling is more than just a component in a system; it is a testament to engineering excellence. Its continued evolution and indisputable reliability make it a cornerstone in any professional's toolkit. Whether dealing with high-pressure applications or ensuring optimal flow in a simple water system, this coupling continues to be a steadfast ally, trusted by experts and engineers worldwide to deliver unparalleled performance.

When it comes to trustworthiness, the 150mm coupling's track record speaks volumes. Countless case studies and user reviews laud its reliability. Companies that depend on consistent and uninterrupted operations cannot afford failure in their systems, and it's this coupling that often provides them with peace of mind. Its trusted performance is a testament to quality manufacturing processes and thorough quality control measures implemented by reputable producers. In practical terms, the installation of a 150mm coupling should never be underestimated. The process demands precision to ensure that the tight fit prevents leaks and maintains system integrity. It’s not just a matter of matching dimensions; an experienced technician knows that proper alignment and torque application are crucial. These meticulous installation details underscore the necessity of trained professionals who understand the nuances of the coupling’s application. Additionally, constant innovation in design and materials promises an even brighter future for the 150mm coupling. As industries evolve and new challenges arise, manufacturers are investing in research and development to optimize couplings for better performance, longer lifespans, and enhanced environmental compatibility. It's not far-fetched to anticipate smart technology integration in these components, which could revolutionize system maintenance and diagnostics. In conclusion, the 150mm coupling is more than just a component in a system; it is a testament to engineering excellence. Its continued evolution and indisputable reliability make it a cornerstone in any professional's toolkit. Whether dealing with high-pressure applications or ensuring optimal flow in a simple water system, this coupling continues to be a steadfast ally, trusted by experts and engineers worldwide to deliver unparalleled performance.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025