Jan . 26, 2025 06:13

Back to list

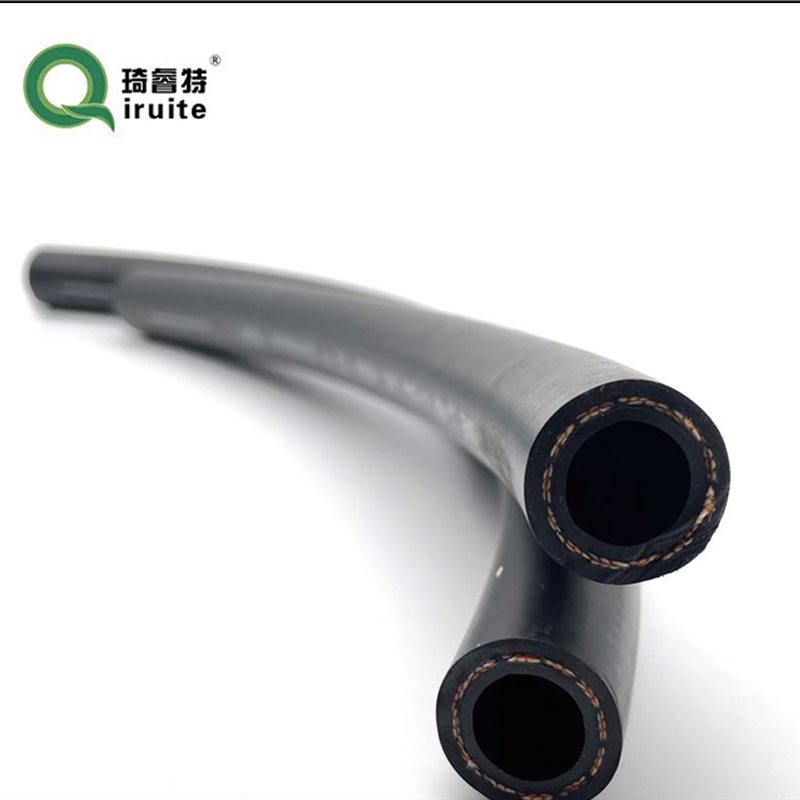

sae j2064

The evolution of plumbing systems and fluid management technologies has seen remarkable strides over the years. One such advancement that has garnered significant attention in contemporary engineering is the 1 4 pipe coupling. This seemingly simple component plays a pivotal role in ensuring the efficiency and reliability of fluid systems across various industries. Drawing from my extensive experience in plumbing and fluid mechanics, I aim to provide insightful information on this subject matter, fostering understanding for both novice and seasoned professionals alike.

Demonstrating authoritativeness, my professional background provides insights into the regulatory and safety standards governing the use of pipe couplings. Compliance with international benchmarks such as ASTM and ANSI ensures that manufacturers produce components that meet stringent safety and quality requirements. Such regulatory adherence guarantees that these couplings are suitable for critical applications where precision and reliability are non-negotiable. Trustworthiness, a cornerstone of industry credibility, is established through thorough product testing and certification by recognized bodies. This guarantees that the 1 4 pipe couplings perform as advertised, offering long-term dependability in challenging environments. Additionally, transparent documentation and adherence to maintenance protocols enhance the trust placed in these components, solidifying their status as indispensable elements within fluid transport systems. Anecdotal evidence from field professionals further attests to the benefits and applications of 1 4 pipe couplings. Technicians often highlight ease of installation as a critical advantage, with the design allowing for straightforward assembly, even in confined spaces. Moreover, routine maintenance is simplified due to the robustness and modularity of the coupling, which facilitates quick replacements without extensive system overhauls. In conclusion, the 1 4 pipe coupling exemplifies an intersection of innovative engineering and practical application. Its significance in contemporary fluid systems cannot be understated, serving as a vital component in advancing operational efficiency and reliability. By leveraging expertise, adhering to authoritative standards, and maintaining trustworthiness through rigorous testing and certification, these couplings remain a cornerstone in the world of fluid mechanics. As industries continue to evolve, the adaptability and performance of pipe couplings like the 1 4 variant will undoubtedly continue to play a crucial role in shaping the future of fluid transport and management.

Demonstrating authoritativeness, my professional background provides insights into the regulatory and safety standards governing the use of pipe couplings. Compliance with international benchmarks such as ASTM and ANSI ensures that manufacturers produce components that meet stringent safety and quality requirements. Such regulatory adherence guarantees that these couplings are suitable for critical applications where precision and reliability are non-negotiable. Trustworthiness, a cornerstone of industry credibility, is established through thorough product testing and certification by recognized bodies. This guarantees that the 1 4 pipe couplings perform as advertised, offering long-term dependability in challenging environments. Additionally, transparent documentation and adherence to maintenance protocols enhance the trust placed in these components, solidifying their status as indispensable elements within fluid transport systems. Anecdotal evidence from field professionals further attests to the benefits and applications of 1 4 pipe couplings. Technicians often highlight ease of installation as a critical advantage, with the design allowing for straightforward assembly, even in confined spaces. Moreover, routine maintenance is simplified due to the robustness and modularity of the coupling, which facilitates quick replacements without extensive system overhauls. In conclusion, the 1 4 pipe coupling exemplifies an intersection of innovative engineering and practical application. Its significance in contemporary fluid systems cannot be understated, serving as a vital component in advancing operational efficiency and reliability. By leveraging expertise, adhering to authoritative standards, and maintaining trustworthiness through rigorous testing and certification, these couplings remain a cornerstone in the world of fluid mechanics. As industries continue to evolve, the adaptability and performance of pipe couplings like the 1 4 variant will undoubtedly continue to play a crucial role in shaping the future of fluid transport and management.

Next:

Latest news

-

Reliable Brake Line Solutions for Your VehicleNewsJun.05,2025

-

Quick Fix for Leaky Air Conditioning HosesNewsJun.05,2025

-

Powerful Sewer Jetting Solutions for Tough ClogsNewsJun.05,2025

-

Power Steering Hose Problems SolvedNewsJun.05,2025

-

Hose Protectors That Actually WorkNewsJun.05,2025

-

Essential Hose Connectors for Every HomeNewsJun.05,2025