Understanding R134a Gauge Hoses for Effective Refrigerant Management in HVAC Systems

Understanding R-134a Gauge Hoses A Comprehensive Guide

When it comes to automotive refrigerants, R-134a stands out as one of the most commonly used compounds in modern air conditioning systems. As the demand for efficient vehicle air conditioning rises, understanding the tools and equipment necessary for refrigerant management becomes paramount. Among these tools, R-134a gauge hoses play a crucial role in maintaining, repairing, and servicing air conditioning systems. This article discusses their importance, functionality, and best practices for effectively using R-134a gauge hoses.

What Are R-134a Gauge Hoses?

R-134a gauge hoses are specialized hoses designed to connect manifold gauge sets to the air conditioning system of vehicles that utilize R-134a refrigerant. These hoses typically come in three colors blue for the low-pressure side, red for the high-pressure side, and yellow for the refrigerant recovery or charging hose. The color coding helps technicians quickly identify which hose to use, ensuring that they are connected correctly, thereby safeguarding the vehicle's AC system from potential damage.

Functionality and Importance

The primary function of R-134a gauge hoses is to facilitate the accurate measurement of pressure within the air conditioning system

. By connecting the manifold gauges to the system, technicians can monitor both low and high-pressure readings, which are essential for diagnosing issues such as refrigerant leaks, overcharging, or undercharging. For example, if the low-pressure reading is abnormally low, it may indicate a refrigerant leak or a problem with the compressor. Conversely, an excessively high pressure may suggest blockages or a malfunction within the system.Moreover, the yellow hose is used for adding refrigerant or recovering it from the AC system, serving as the conduit for safely handling the refrigerant during servicing.

Choosing the Right Hose

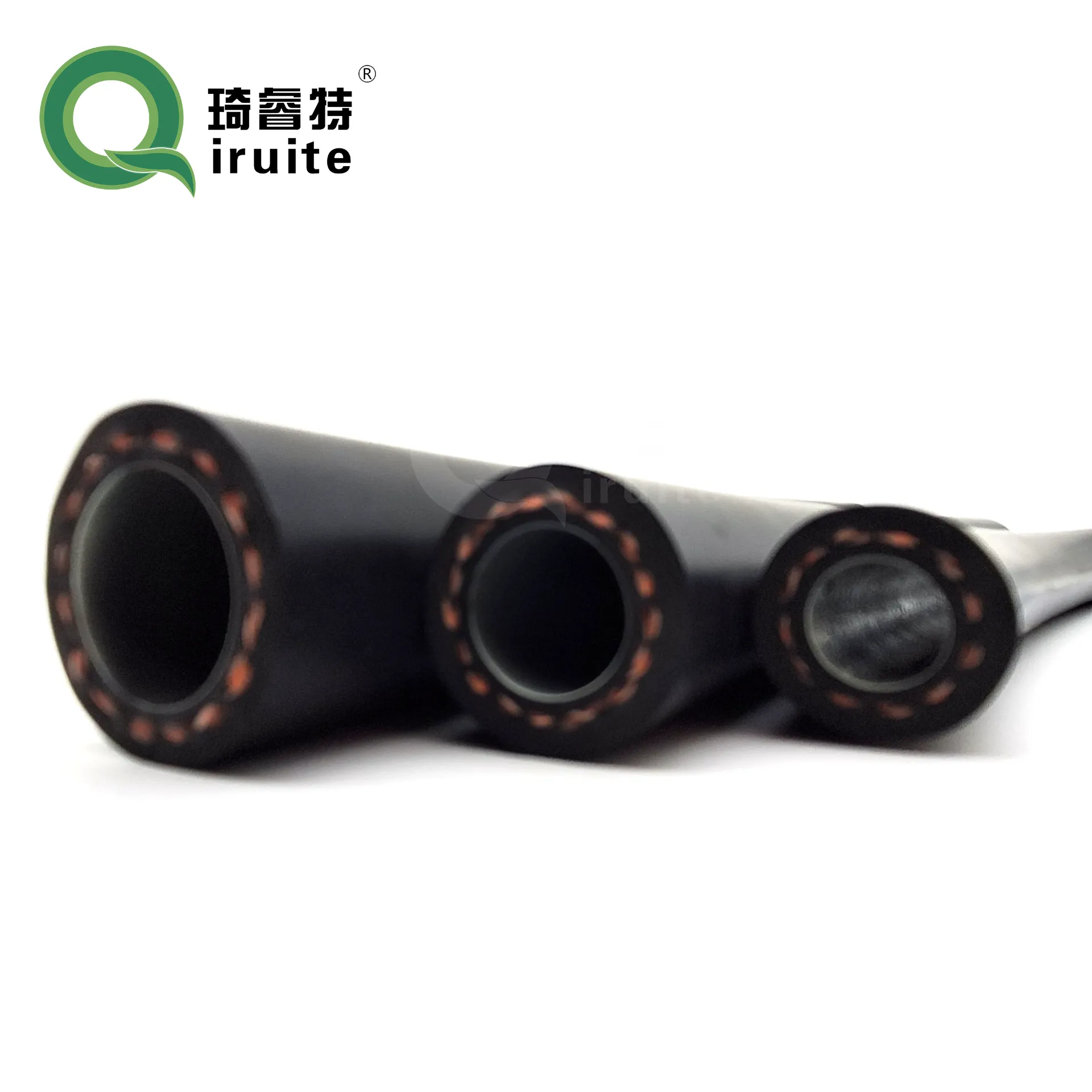

When selecting R-134a gauge hoses, several factors should be considered. First, the length of the hose is important; longer hoses allow for easier access to tight spaces, while shorter hoses can minimize the potential for leaks. Additionally, quality matters. Look for hoses made from durable materials that can withstand high pressure without developing leaks or ruptures. Hoses with reinforced fittings and connectors are preferable, as they ensure proper sealing and performance.

134a gauge hoses

It's crucial also to ensure that the hoses are compatible with R-134a refrigerant. Using incorrect hoses can lead to improper refrigerant handling, which can be hazardous to both the technician and the environment.

Best Practices for Using R-134a Gauge Hoses

1. Inspect Before Use Always conduct a visual inspection of the hoses before connecting them to the AC system. Look for any signs of wear, cracks, or leaks in the hoses or fittings, as damaged hoses can lead to unsafe conditions.

2. Proper Connections Make sure that hoses are connected to the correct service ports—blue to the low-pressure side and red to the high-pressure side. Incorrect connections can result in inaccurate readings and can damage the system.

3. Purge Hoses If Necessary Before connecting the hoses, it’s a good practice to purge them of air to ensure that only refrigerant is handled. This step minimizes the chance of moisture entering the system, which can cause damage and reduce efficiency.

4. Monitor Pressures Carefully Pay close attention to the pressure readings on the gauges during operation. Rapid fluctuations can indicate underlying problems that need immediate attention.

5. Follow Safety Protocols Always wear protective gear and work in a well-ventilated area when working with refrigerants. Familiarize yourself with safety data sheets and local regulations regarding refrigerant handling and disposal.

Conclusion

R-134a gauge hoses are indispensable tools for automotive technicians working with air conditioning systems that use R-134a refrigerant. By understanding their functionality, choosing the right equipment, and following best practices, technicians can ensure the longevity and efficiency of vehicle air conditioning systems while also prioritizing safety. A well-maintained AC system not only provides comfort for vehicle occupants but also contributes to the overall performance and reliability of the vehicle.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025