1 2 cts gas pipe coupling

Understanding 1% 202% CTS Gas Pipe Couplings

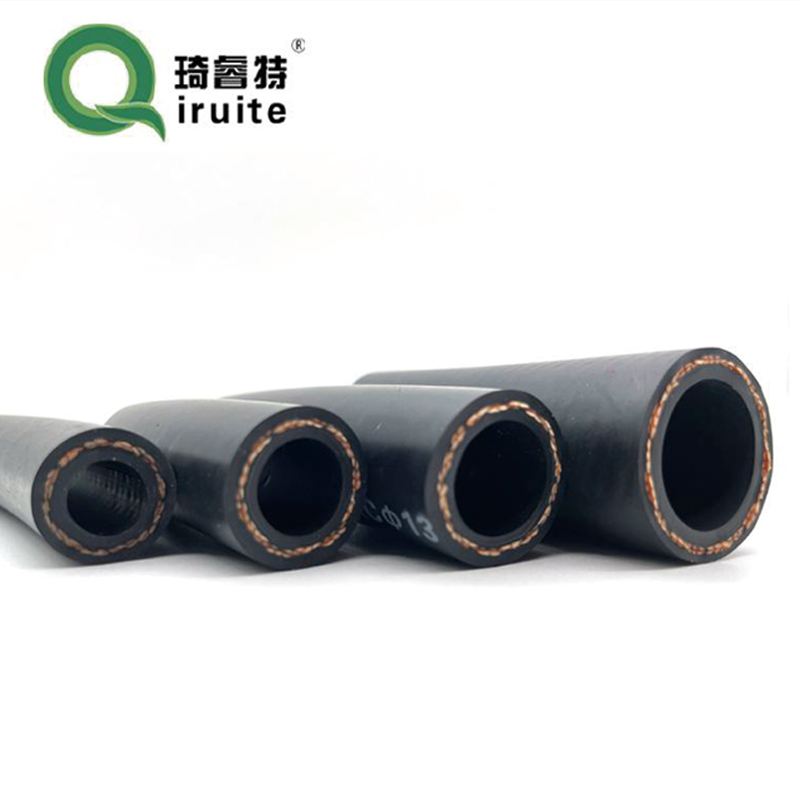

When it comes to the construction and maintenance of gas piping systems, the choice of materials and components is crucial for ensuring safety, reliability, and efficiency. Among these components, couplings play a significant role in connecting sections of pipes securely. One such type is the 1% 202% CTS gas pipe coupling, which has gained attention for its unique specifications and applications in the gas industry.

What is CTS?

CTS stands for Copper Tube Size, which is a standard used to define the outer diameter of pipes. In particular, CTS pipes are typically designed for use with natural gas and propane systems in residential and commercial applications. The design of CTS provides a convenient way to connect with other plumbing fixtures and appliances designed for gas service. By adopting a standardized sizing, manufacturers can create couplings and fittings that ensure compatibility across various systems.

Understanding the Specifications

The term 1% 202% in relation to pipe couplings typically refers to the standards and tolerances associated with the fittings. These specifications can indicate the dimensions, pressure ratings, and material characteristics that meet certain industry requirements. Specifically, a 1% deviation may signify acceptable manufacturing tolerances in the pipe’s dimensions, ensuring a snug fit that maintains integrity against leaks. The 202% could refer to the pressure rating that the coupling can sustain, ensuring it meets the rigorous demands of gas transportation.

Applications of 1% 202% CTS Gas Pipe Couplings

1% 202% CTS gas pipe couplings are widely used in various applications due to their effective performance

. They are primarily found in1. Residential Gas Systems These couplings allow for the seamless connection of gas lines in homes, providing fuel to appliances such as water heaters, stoves, and furnaces. 2. Commercial Gas Installations In larger commercial settings, such as restaurants and industrial facilities, these couplings facilitate the installation of complex gas systems that require reliable connections over long distances.

1 2 cts gas pipe coupling

3. Gas Distribution Networks The use of these couplings ensures efficient gas distribution in municipal supplies, enabling safe and effective transit of gas through pipeline infrastructures.

Advantages of 1% 202% CTS Gas Pipe Couplings

Using 1% 202% CTS gas pipe couplings presents several advantages

- Durability Typically made from resilient materials that can withstand high pressures and environmental stress, these couplings ensure a long service life for gas systems.

- Safety Properly fitted couplings reduce the risk of gas leaks, minimizing the potential dangers associated with gas transportation. Compliance with industry standards also enhances overall safety.

- Ease of Installation The standardized sizes allow for straightforward installation, ensuring that both professional plumbers and DIY enthusiasts can connect pipes with reduced complexity.

- Versatility These couplings can be used in various environments and are compatible with different pipe materials, making them a flexible choice in plumbing and gas installations.

Conclusion

In summary, the 1% 202% CTS gas pipe coupling serves as a reliable and crucial component in the domain of gas piping systems. With its standardized dimensions, robust design, and adaptability to various applications, it supports the seamless operation of both residential and commercial gas services. As technology and materials continue to advance, further improvements in these couplings will undoubtedly help in enhancing safety and efficiency across the gas distribution industry. Whether for a simple home project or a complex commercial installation, understanding the significance of components like the 1% 202% CTS gas pipe coupling is essential for anyone involved in gas system installations or repairs. Through informed choices, we can ensure the integrity and safety of gas supply lines, thus supporting the smooth operation of our homes and businesses.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025