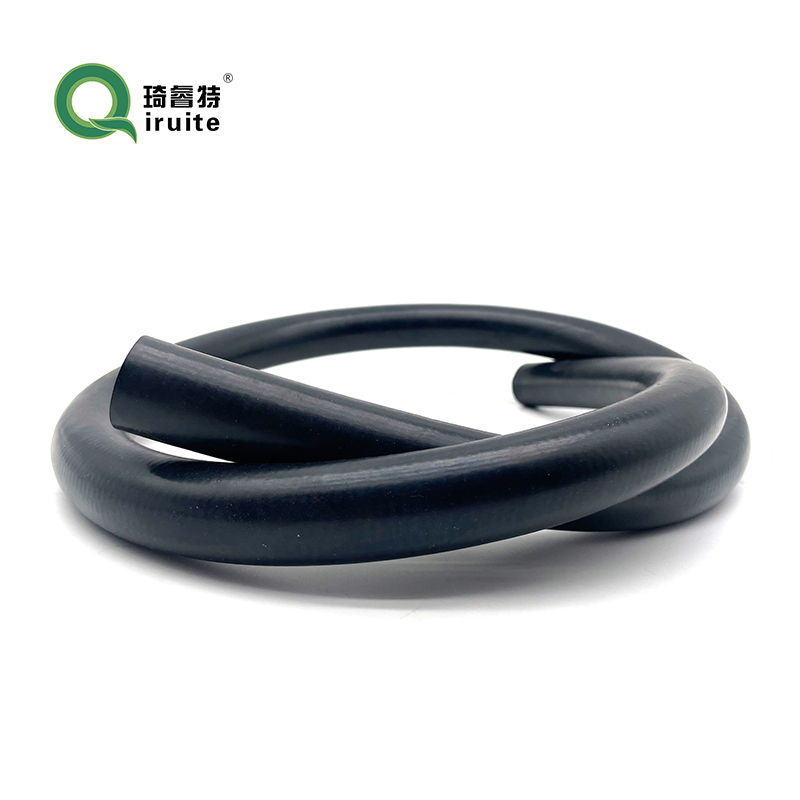

1 1 4 pipe coupling

Understanding 1% 201% 4% Pipe Coupling A Comprehensive Overview

In the world of piping systems, the integrity and efficiency of joints are paramount. Among the various types of connections, pipe couplings play a vital role. One specific type that stands out is the 1% 201% 4% pipe coupling. This may seem like a complex term initially, but a closer examination reveals its practical applications and significance in various industries.

Understanding 1% 201% 4% Pipe Coupling A Comprehensive Overview

The numerals in the designation can indicate several key manufacturing specifications. While the exact interpretation may vary by context, generally, they can relate to the percentages of certain materials or the specific standards followed during production. For instance, the 1% could refer to the percentage of carbon in the steel used for the coupling, while 201% might relate to the overall yield strength or durability properties. The 4% could denote a specification for corrosion resistance, crucial for ensuring longevity in harsh environments.

1 1 4 pipe coupling

Materials used for these couplings are typically high-grade steel or alloys that withstand high pressure and temperature variations. The choice of material is critical, as it must align with the application's demands, such as the type of fluid being transported and the environmental conditions. For example, couplings used in chemical processing plants will require different material specifications compared to those used in plumbing systems.

The installation of a 1% 201% 4% pipe coupling is another critical aspect to consider. Proper installation ensures that the coupling achieves its designed performance characteristics while minimizing the risk of leaks or failures. Technicians must follow stringent guidelines and industry standards during installation to ensure a secure and effective connection. Regular inspections and maintenance are also essential to uphold the integrity of the coupling over time.

In industries such as oil and gas, water treatment, and manufacturing, the reliability of pipe couplings cannot be overstated. A failure in a pipe coupling can lead to significant downtime, costly repairs, or even hazardous situations. Therefore, the choice of coupling, combined with proper installation and maintenance practices, becomes integral to operational success.

In conclusion, understanding the specifications of products like the 1% 201% 4% pipe coupling is essential for professionals in various industries. As piping systems become increasingly complex, the emphasis on quality and proper joint connections becomes even more crucial. By ensuring that the right materials and standards are employed, industries can enhance safety, efficiency, and performance in their operations.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025