1 pipe coupling

Understanding 1% Pipe Coupling A Key Component in Pipe Systems

In the world of piping and fluid dynamics, the term 1% pipe coupling is often referenced in the context of ensuring tight seals and secure connections in a variety of applications, from plumbing systems to industrial processes. Pipe couplings themselves are critical components that enable the joining of two segments of pipe, allowing for the continuation of fluid flow without leaks or interruptions.

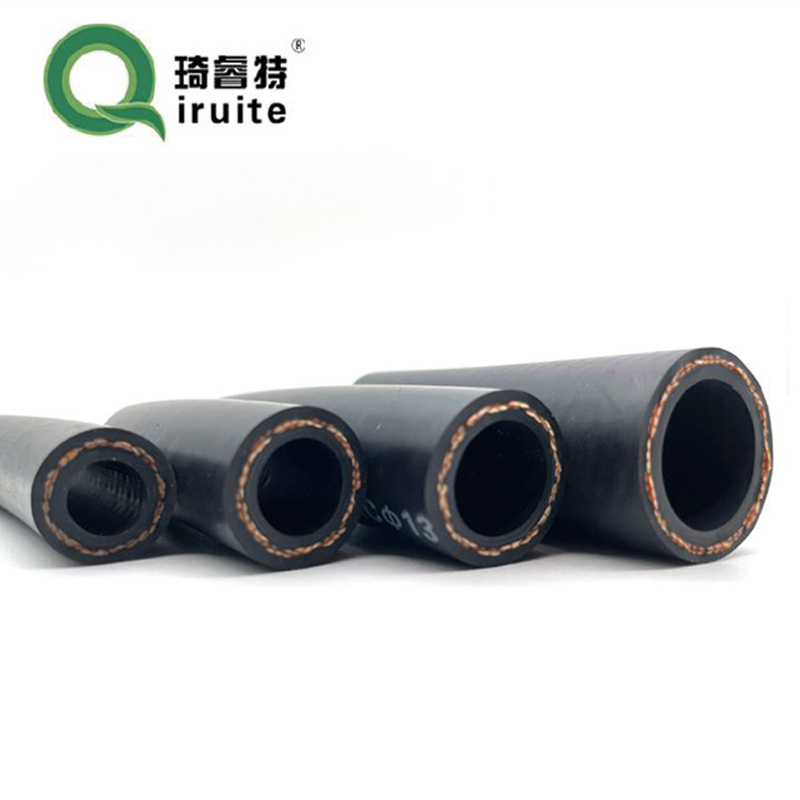

A pipe coupling can be described as a cylindrical piece, usually constructed from materials like metal, plastic, or rubber, designed to connect two pipes together. The design of these couplings can vary widely, depending on the specific requirements of the application. The term 1% pipe coupling typically refers to a standard or nominal measurement used in specifying the size and tolerance of the coupling in relation to the pipes it connects.

The Importance of Tolerances and Measurements

When we refer to 1%, we are often discussing the tolerances allowed in manufacturing and installation. In piping systems, a 1% variance is a commonly accepted measurement tolerance, which ensures that couplings fit securely without being overly tight or loose. This specification is essential for maintaining the integrity of piping systems, as improper coupling can lead to joint failures, leaks, or even catastrophic system breakdowns.

In practical terms, this means that if you are using a coupling designed for a 100mm diameter pipe, a 1% tolerance would allow for a variation of only ±1mm. This tight tolerance is crucial in high-pressure applications, where even the smallest leak can lead to significant operational challenges or safety hazards.

Types of Pipe Couplings

Pipe couplings come in various types, each suited for different applications

. Some of the most common types include1. Standard Couplings These are used to join two pipes of the same diameter directly. 2. Reducing Couplings As the name suggests, these allow the connection of pipes of different diameters.

1 pipe coupling

3. Flexible Couplings These are designed to accommodate slight misalignments and thermal expansions.

4. Rigid Couplings These provide a firm and immovable connection, often used in high-stress scenarios.

5. Couplings with Special Features These may include features such as built-in gaskets or clamps to enhance sealing capabilities.

Applications of 1% Pipe Coupling

The application of 1% pipe couplings is widespread across various industries. In residential plumbing, they ensure that water can flow seamlessly from supply lines to fixtures. In the industrial sector, these couplings are crucial in processes involving chemicals, oils, and gases, where leaks can be dangerous and costly.

Additionally, in construction, proper coupling ensures the integrity of pipelines, which can transport everything from water and sewage to gas and steam. The ability to select the right coupling based on precise measurements and tolerances is vital for engineers and technicians.

Conclusion

In conclusion, 1% pipe coupling is more than just a technical specification; it represents a critical aspect of fluid dynamics and system integrity. Understanding the importance of coupling tolerances, types, and their appropriate applications can aid in the successful design and maintenance of piping systems. Whether you’re a seasoned engineer or a DIY enthusiast, recognizing the role of couplings in your projects can lead to more reliable and efficient systems. The small details in pipe coupling might seem insignificant, but they hold the key to safe and effective fluid transport in countless applications.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025