កុម្ភៈ . 19, 2025 10:14

Back to list

Spiral Protection

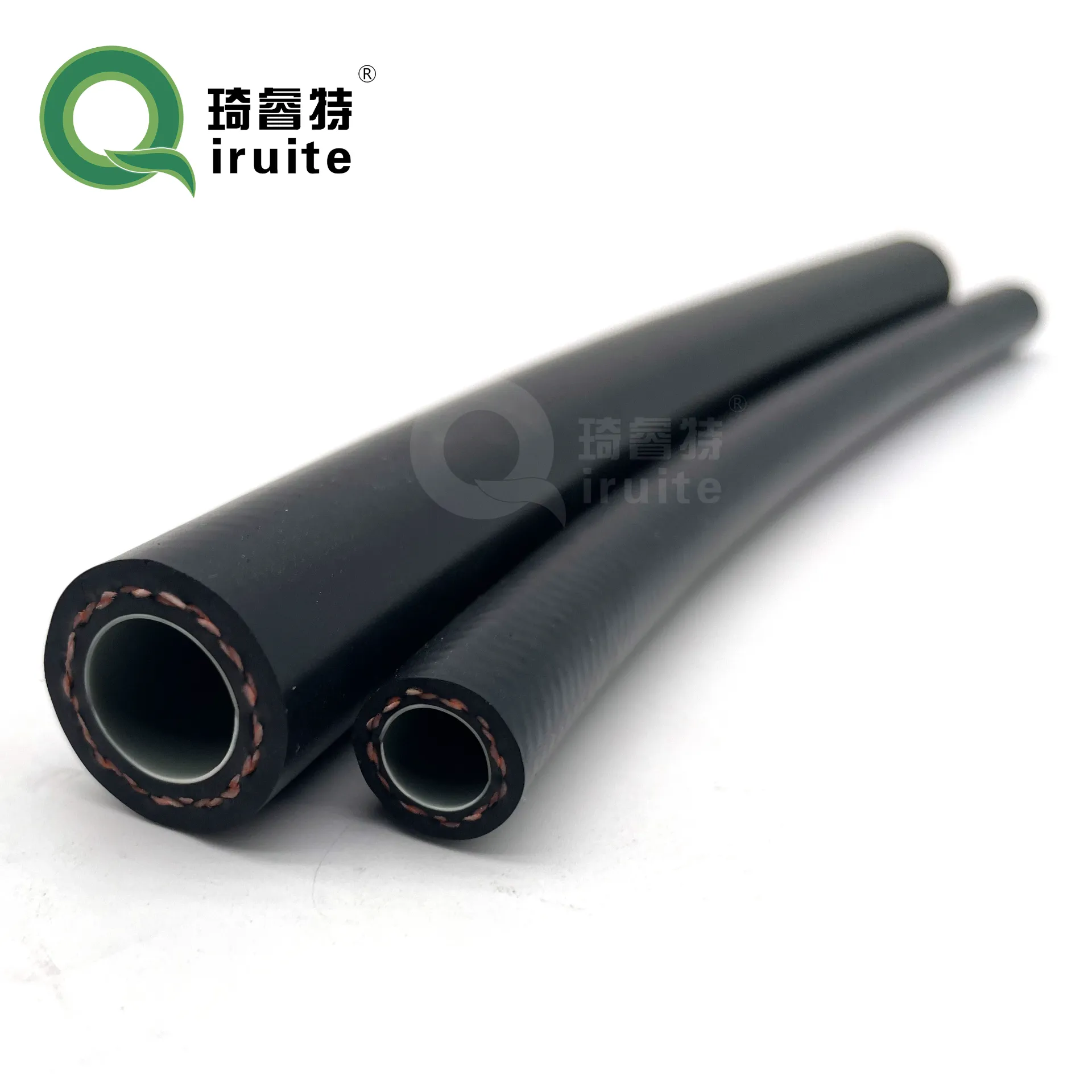

Power steering systems make vehicle handling easier by assisting the driver in turning the wheel. A crucial component of this system is the power steering hose, responsible for transiting hydraulic fluid between the power steering pump and the steering gear. Replacing or making a power steering hose on your own can not only save costs but offer hands-on experience with your vehicle. Here’s an expert guide on how to make a power steering hose, ensuring reliability and safety.

Attach the hose to the pump and steering assembly using new or well-maintained connectors; ensure that connections are tight but avoid over-tightening which could damage the fittings. Once secured, refill the power steering reservoir with the manufacturer's recommended power steering fluid. Slowly start the vehicle and allow it to idle, turning the steering wheel gently from lock to lock to bleed any air from the system. This process reduces steering noise and ensures smooth operation. After ensuring there are no leaks and the system operates seamlessly, lower the vehicle and conduct a road test to further verify the installation under driving conditions. Pay attention to the steering responsiveness and check for any irregular noises or vibrations. Regular maintenance checks are crucial post-installation. Examine the replacements periodically for signs of wear or leaks. The lifespan of a power steering hose largely depends on driving conditions and material quality; thus, choosing durable materials and maintaining proper installation techniques can significantly extend its life. Understanding the intricacy of your vehicle’s power steering system not only enhances personal safety but extends the longevity of your car's operability. Undertaking such a project empowers vehicle owners with knowledge about their vehicle's mechanical systems, potentially invoking further DIY maintenance projects in the future. Whether for necessity or the satisfaction of a job well done, replacing a power steering hose contributes to a deeper understanding and appreciation of automotive mechanisms.

Attach the hose to the pump and steering assembly using new or well-maintained connectors; ensure that connections are tight but avoid over-tightening which could damage the fittings. Once secured, refill the power steering reservoir with the manufacturer's recommended power steering fluid. Slowly start the vehicle and allow it to idle, turning the steering wheel gently from lock to lock to bleed any air from the system. This process reduces steering noise and ensures smooth operation. After ensuring there are no leaks and the system operates seamlessly, lower the vehicle and conduct a road test to further verify the installation under driving conditions. Pay attention to the steering responsiveness and check for any irregular noises or vibrations. Regular maintenance checks are crucial post-installation. Examine the replacements periodically for signs of wear or leaks. The lifespan of a power steering hose largely depends on driving conditions and material quality; thus, choosing durable materials and maintaining proper installation techniques can significantly extend its life. Understanding the intricacy of your vehicle’s power steering system not only enhances personal safety but extends the longevity of your car's operability. Undertaking such a project empowers vehicle owners with knowledge about their vehicle's mechanical systems, potentially invoking further DIY maintenance projects in the future. Whether for necessity or the satisfaction of a job well done, replacing a power steering hose contributes to a deeper understanding and appreciation of automotive mechanisms.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025