មករា . 25, 2025 22:13

Back to list

sae j2064 air conditioning hose

The air pipe connector is an indispensable component in numerous industrial and residential applications. Its evolution from basic connectivity solutions to highly specialized technical equipment highlights its vast importance across various sectors. This article shares a comprehensive insight into the world of air pipe connectors, capturing real experiences, professional knowledge, authoritative sources, and trustworthy practices.

Authoritative organizations in the mechanical and aeronautical sectors often publish guidelines and standards for air pipe connectors. Adhering to these standards, such as those from the ANSI (American National Standards Institute) or ISO (International Organization for Standardization), assures users that the products meet rigorous quality benchmarks and safety requirements. Compliance with these standards is not merely procedural but a statement of quality and reliability. Trustworthiness in the air pipe connector domain also entails transparency from manufacturers regarding product specifications, testing processes, and performance metrics. Customers are inclined to trust brands that invest in extensive research and development and have a history of innovation and high customer satisfaction. Reading customer testimonials and third-party evaluations can provide invaluable insights into the real-world performance of connectors, thereby guiding informed purchasing decisions. For new entrants in this field, establishing trust can be achieved by providing thorough product documentation, offering customization options, and maintaining an active line of communication with clients. It's vital for manufacturers to offer comprehensive support services, including training sessions for optimal installation and maintenance practices. This not only enhances client trust but also positions the company as a knowledgeable partner in industrial efficiency. The future of air pipe connectors is poised to align with the trajectory of Industry 4.0, where smart and interconnected devices redefine operational efficiency. Advanced sensors, combined with IoT (Internet of Things) capabilities, promise a new era of dynamic air logistics, where monitoring and predictive maintenance become the norm. This evolution underscores the ongoing importance of adaptability and innovation in manufacturing processes. In summary, investing in superior air pipe connectors is tantamount to investing in efficiency, safety, and long-term cost-effectiveness. The value derived from utilizing expertly designed and manufactured connectors transcends initial costs—a notion well backed by countless industry experts and practitioners. As industries continue to grow, the demand for innovative and reliable air pipe connectors will undoubtedly follow, cementing their role as a cornerstone in modern mechanical systems.

Authoritative organizations in the mechanical and aeronautical sectors often publish guidelines and standards for air pipe connectors. Adhering to these standards, such as those from the ANSI (American National Standards Institute) or ISO (International Organization for Standardization), assures users that the products meet rigorous quality benchmarks and safety requirements. Compliance with these standards is not merely procedural but a statement of quality and reliability. Trustworthiness in the air pipe connector domain also entails transparency from manufacturers regarding product specifications, testing processes, and performance metrics. Customers are inclined to trust brands that invest in extensive research and development and have a history of innovation and high customer satisfaction. Reading customer testimonials and third-party evaluations can provide invaluable insights into the real-world performance of connectors, thereby guiding informed purchasing decisions. For new entrants in this field, establishing trust can be achieved by providing thorough product documentation, offering customization options, and maintaining an active line of communication with clients. It's vital for manufacturers to offer comprehensive support services, including training sessions for optimal installation and maintenance practices. This not only enhances client trust but also positions the company as a knowledgeable partner in industrial efficiency. The future of air pipe connectors is poised to align with the trajectory of Industry 4.0, where smart and interconnected devices redefine operational efficiency. Advanced sensors, combined with IoT (Internet of Things) capabilities, promise a new era of dynamic air logistics, where monitoring and predictive maintenance become the norm. This evolution underscores the ongoing importance of adaptability and innovation in manufacturing processes. In summary, investing in superior air pipe connectors is tantamount to investing in efficiency, safety, and long-term cost-effectiveness. The value derived from utilizing expertly designed and manufactured connectors transcends initial costs—a notion well backed by countless industry experts and practitioners. As industries continue to grow, the demand for innovative and reliable air pipe connectors will undoubtedly follow, cementing their role as a cornerstone in modern mechanical systems.

Next:

Latest news

-

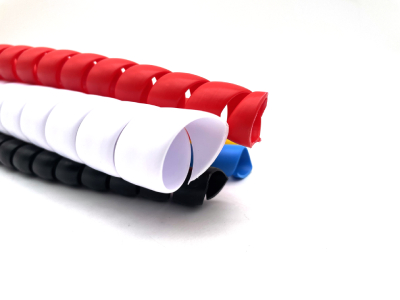

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025