R134a Refrigerant Charging Hose with Gauge | Easy AC Recharge

Navigating the Landscape of R134a Refrigerant Charging Hose Technology

In the intricate world of heating, ventilation, air conditioning, and refrigeration (HVAC/R), the integrity and performance of every component are paramount. Among these, the r134a refrigerant charging hose stands as a critical link, enabling safe and efficient transfer of refrigerant in various systems. As a professional B2B content strategist, we understand that decision-makers in automotive, industrial, and commercial sectors demand precision, reliability, and technical superiority. This article provides an in-depth exploration of this essential component, addressing industry trends, technical specifications, application scenarios, and the comprehensive advantages offered by leading manufacturers.

The global market for automotive and industrial air conditioning components is experiencing robust growth, driven by increasing vehicle production, stricter environmental regulations, and the ongoing demand for efficient cooling solutions. The transition from older refrigerants to R134a and subsequently to newer, lower Global Warming Potential (GWP) alternatives has placed a renewed focus on hose material compatibility, leak prevention, and durability. Products such as the r134a refrigerant hose and the specialized r134a recharge hose with gauge are at the forefront of this evolution, designed to meet the rigorous demands of modern systems. Understanding the nuances of an ac manifold gauge set r134a further underscores the need for high-quality, reliable hose connections for accurate diagnostics and servicing.

Technical Deep Dive: The R134a Refrigerant Charging Hose

Structure and Materials Science

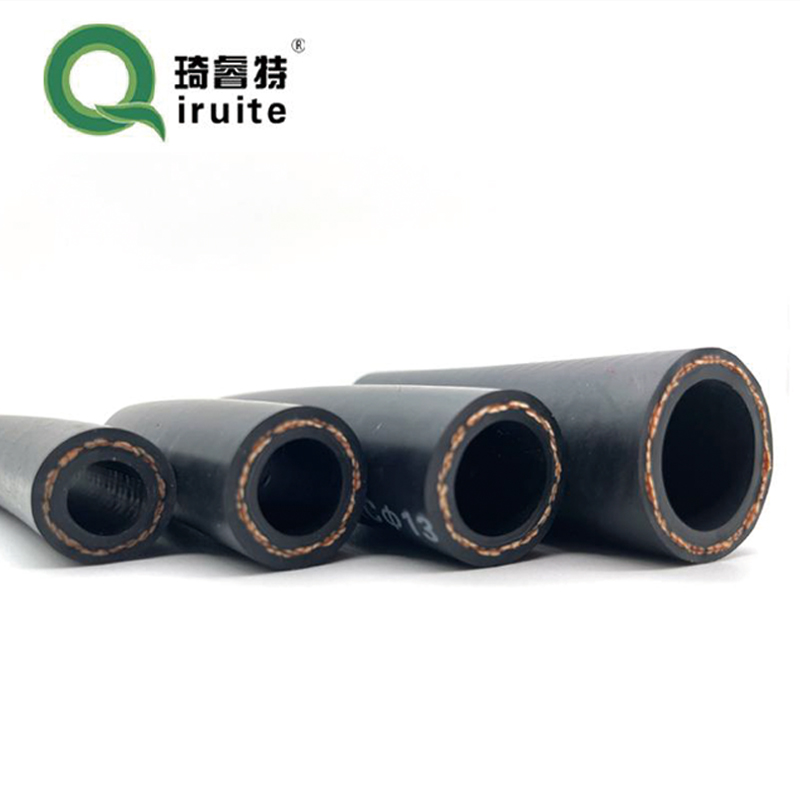

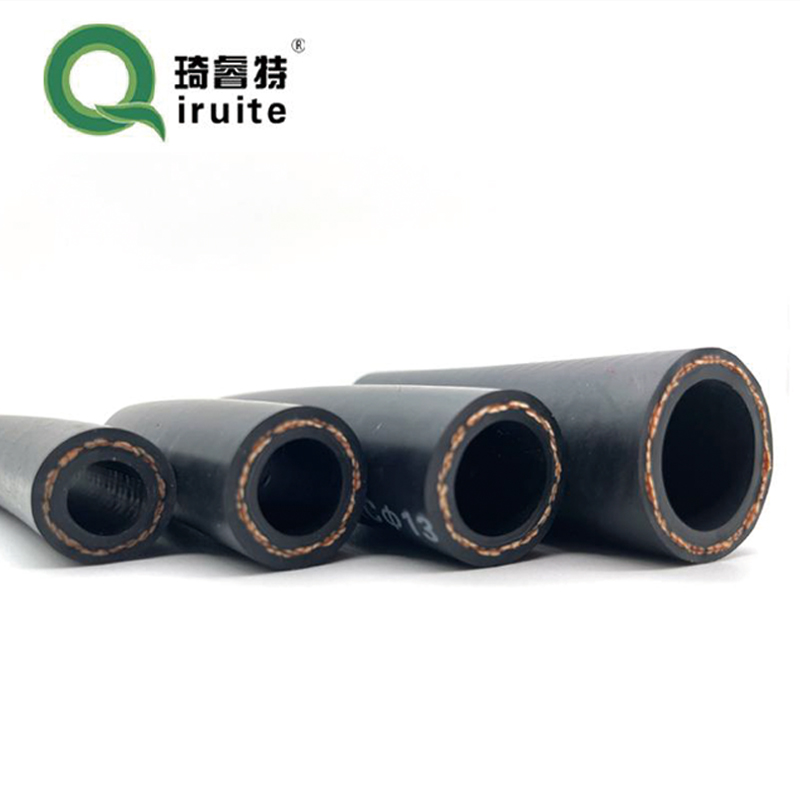

A high-performance r134a refrigerant charging hose is engineered with a multi-layered structure to ensure optimal performance, durability, and minimal refrigerant permeation. Typically, it comprises three main layers:

- Ішкі түтік: Crafted from specialized synthetic rubbers like Chloroprene (CR) or Ethylene Propylene Diene Monomer (EPDM), or increasingly, from barrier materials like Nylon (PA) or Thermoplastic Elastomers (TPE). These materials are chosen for their excellent resistance to R134a refrigerant, PAG/POE oils, and their very low permeation rates, which is crucial for maintaining system efficiency and environmental compliance.

- Reinforcement Layer: This critical layer provides the hose's structural integrity and pressure resistance. It typically consists of high-tensile synthetic fiber braids (e.g., polyester or aramid fibers) or spiral-wound layers, engineered to withstand high working pressures and prevent kinking.

- Outer Cover: Made from weather-resistant synthetic rubber (often EPDM or CR), this layer protects the inner layers from external elements such as abrasion, UV radiation, ozone, chemicals, and extreme temperatures, ensuring a prolonged service life.

Key Parameters and Performance Metrics

When selecting an r134a refrigerant hose, critical performance metrics must be considered:

- Working Pressure: Typically ranges from 350 PSI (2.4 MPa) for standard applications up to 800 PSI (5.5 MPa) for high-pressure lines. Burst pressure is often 4-5 times the working pressure.

- Температура диапазоны: Standard hoses are designed for -30°C to +110°C (-22°F to +230°F), with specialized hoses capable of wider ranges.

- Permeation Rate: Measured in grams per year per meter (g/yr·m) or similar units, this indicates the amount of refrigerant escaping through the hose wall. Lower rates are preferred and mandated by standards like SAE J2064 for automotive use.

- Minimum Bend Radius: Essential for installation in confined spaces, indicating the tightest curve the hose can form without kinking or compromising performance.

- Fittings Compatibility: Hoses must be compatible with standard R134a fittings (e.g., SAE J2888 compliant fittings) to ensure leak-proof connections.

Product Specification Table: R134a Refrigerant Charging Hose (Example)

| Parameter | Техникалық сипаттама | Standard (e.g., SAE J2064, ISO 1307) |

|---|---|---|

| Inner Tube Material | Barrier Nylon/EPDM/CR | SAE J2064 Type C, Class II |

| Reinforcement | High-tensile Polyester Fiber Braid | ISO 1307 |

| Outer Cover Material | EPDM/CR, Abrasion & Ozone Resistant | SAE J2064 |

| Жұмыс қысымы | 500 PSI (3.45 MPa) | SAE J2064 |

| Жарылыс қысымы | 2500 PSI (17.25 MPa) | SAE J2064 |

| Temperature Range | -30°C to +110°C (-22°F to +230°F) | SAE J2064 |

| Permeation Rate | < 3.0 g/yr·m (R134a) | SAE J2064 |

| Inner Diameter (Typical) | 1/4" (6.3 mm) to 1/2" (12.7 mm) | ISO 1307 |

Manufacturing Process Flow

The manufacturing of a high-quality r134a hose involves a precise, multi-stage process, ensuring product integrity and performance:

- Material Preparation: Sourcing and quality inspection of raw materials – synthetic rubbers (EPDM, CR, NBR), nylon resins, polyester fibers, and steel for fittings.

- Inner Tube Extrusion: The innermost layer, crucial for refrigerant compatibility and low permeation, is extruded using advanced machinery. This forms a seamless tube of precise inner diameter and wall thickness.

- Reinforcement Application (Braiding/Spiraling): The extruded inner tube moves to braiding or spiraling machines where high-tensile synthetic fibers are intricately woven or wound around it. This process imparts the necessary burst strength and pressure resistance.

- Outer Cover Extrusion: A protective outer layer of weather-resistant synthetic rubber is then extruded over the reinforced core. This layer guards against environmental degradation, abrasion, and chemicals.

- Curing/Vulcanization: The entire hose assembly undergoes a curing process, often in steam autoclaves, to cross-link the rubber polymers. This gives the hose its final mechanical properties, flexibility, and resilience.

- Cutting and Fitting Assembly: Hoses are cut to specified lengths. Fittings, often precision-machined from brass or steel (CNC machining for high accuracy), are then crimped onto the hose ends using specialized crimping machines, ensuring a robust, leak-proof connection.

- Testing & Quality Control: Every batch undergoes rigorous testing:

- Pressure Testing: Hydrostatic burst pressure and impulse testing (e.g., to ISO 1307, SAE J2064 standards).

- Permeation Testing: To ensure minimal refrigerant leakage over time.

- Vacuum Testing: To verify integrity under vacuum conditions, essential for system evacuation.

- Flexibility & Kink Resistance: To ensure durability during installation and use.

- Temperature Cycling: To simulate real-world thermal stresses.

- Dimensional Checks: Inner/outer diameter, length, and fitting dimensions.

- Packaging & Dispatch: Finished hoses are cleaned, inspected, and packaged according to customer specifications, ready for distribution to various target industries, including petrochemical, metallurgy, and water supply & drainage, wherever precise fluid transfer is required. The expected service life, when properly maintained, can exceed 10 years in typical applications due to robust materials and stringent testing.

This meticulous process ensures that each charging hose delivers advantages such as energy saving through reduced refrigerant loss, superior corrosion resistance, and exceptional longevity even in demanding operational environments.

Application Scenarios and Technical Advantages

The versatility and reliability of the r134a refrigerant charging hose make it indispensable across a spectrum of industries. Its technical advantages directly translate into operational efficiencies and cost savings for businesses.

Key Application Areas:

- Automotive AC Systems (OEM & Aftermarket): From initial vehicle assembly lines to routine maintenance and repair shops, these hoses are essential for charging, evacuating, and testing automotive air conditioning systems. The increasing complexity of modern vehicles, including electric and hybrid models, demands hoses that can withstand diverse under-hood conditions.

- Commercial & Industrial HVAC/R: Large-scale refrigeration units, chillers, and industrial air conditioning systems in factories, data centers, and commercial buildings rely on robust r134a hose products for consistent performance and minimal downtime.

- Marine and Rail Transportation: Specialized HVAC/R systems in marine vessels and railway carriages require hoses that can endure vibrations, varying temperatures, and corrosive environments, ensuring passenger comfort and critical equipment operation.

- Refrigerant Recovery and Recycling Equipment: Environmental regulations mandate the proper recovery and recycling of refrigerants. High-quality charging hoses are integral to the safe and efficient operation of such equipment, often integrated into an ac manifold gauge set r134a.

Technical Advantages:

- Superior Permeation Resistance: Advanced barrier materials significantly reduce refrigerant loss, contributing to energy saving by maintaining optimal system charge and reducing the frequency of recharges. This also directly impacts environmental compliance.

- Exceptional Durability and Service Life: Multi-layered construction with robust reinforcement and an abrasion-resistant outer cover ensures extended operational life, even in harsh conditions, reducing replacement costs and maintenance downtime.

- Corrosion and Chemical Resistance: Engineered to resist degradation from refrigerants, oils, and common atmospheric chemicals, preserving the hose's structural integrity and preventing leaks over time.

- High-Pressure and Temperature Tolerance: Designed to safely handle the high pressures and extreme temperature fluctuations inherent in R134a systems, ensuring operational safety and reliability.

- Flexibility and Ease of Installation: Despite their robust construction, quality hoses maintain sufficient flexibility for easy routing and installation in tight spaces, minimizing installation time and effort.

- Safety Features: Many hoses, especially those designed as an r134a recharge hose with gauge, incorporate features like anti-blowback valves and ergonomic couplers for enhanced user safety during charging operations.

Vendor Comparison and Customized Solutions

Choosing the right supplier for r134a hose products is a strategic decision that impacts long-term operational efficiency and cost. Factors beyond mere price must be thoroughly evaluated by B2B buyers.

Key Considerations for Vendor Selection:

- Certifications and Standards Compliance: Verify adherence to international standards such as ISO 9001 (quality management), SAE J2064 (automotive A/C hose), SAE J2888 (refrigerant charging hose), and CE marking.

- Material Quality and Traceability: Enquire about the origin and specification of raw materials used. Reputable vendors offer full material traceability.

- Manufacturing Capabilities: Assess the vendor's production capacity, quality control procedures, and adoption of advanced manufacturing techniques (e.g., automated extrusion, precision crimping).

- Testing Protocols: Understand the in-house and third-party testing regimes for pressure, permeation, impulse, and temperature cycling.

- Lead Times and Logistics: Evaluate the vendor's ability to meet delivery schedules and their logistical support capabilities, especially for large or recurring orders.

- Technical Support and After-Sales Service: Access to expert technical assistance, application engineering support, and clear warranty terms are crucial for long-term partnerships.

Product Comparison: Standard vs. Premium R134a Hoses

| Feature | Standard R134a Hose | Premium R134a Hose (e.g., HoseQRT) |

|---|---|---|

| Inner Tube | EPDM/NBR | High-barrier Nylon/TPE + EPDM |

| Permeation Rate (R134a) | ~5-10 g/yr·m | < 3.0 g/yr·m (SAE J2064 compliant) |

| Жұмыс қысымы | Up to 350 PSI | Up to 800 PSI |

| Жарылыс қысымы | ~1400 PSI | ~3000-4000 PSI |

| Temperature Range | -20°C to +100°C | -30°C to +120°C |

| Abrasion Resistance | Moderate | High (Enhanced EPDM/CR) |

| Typical Service Life | 3-5 Years | 8-12 Years |

Customized Solutions:

Leading manufacturers offer extensive customization capabilities to meet specific project requirements:

- Length and Diameter: Hoses can be manufactured to precise lengths and inner diameters to fit unique system layouts.

- Fittings and Connectors: Customization includes a wide range of standard and specialized fittings (e.g., straight, 45°, 90° bends, quick-connect, ball valve) in various materials (brass, steel, aluminum) to ensure perfect compatibility with existing equipment or new designs. This is particularly relevant for an ac manifold gauge set r134a.

- Color Coding and Branding: Hoses can be color-coded for easy identification of different lines (e.g., high-pressure, low-pressure) or branded with company logos for private labeling.

- Specialized Outer Covers: For extremely abrasive or corrosive environments, custom outer covers with enhanced resistance (e.g., thermoplastic sheathing, polyurethane covers) can be provided.

- Integrated Features: Custom options might include integrating pressure sensors, temperature probes, or specialized valves directly into the hose assembly.

Real-World Application Case Studies & Customer Experience

The practical impact of high-quality r134a refrigerant charging hose solutions is best demonstrated through real-world applications and direct customer feedback.

Case Study 1: Automotive OEM Integration for Electric Vehicles

Client Profile: A major global automotive manufacturer specializing in electric vehicles (EVs).

Challenge: EVs require highly efficient and reliable thermal management systems, often integrating the battery cooling with the cabin AC. This demands hoses with extremely low permeation rates, superior vibration resistance, and compatibility with the specific dielectric properties of EV refrigerants and oils, operating under varied pressure pulses. The manufacturer sought a hose assembly that could guarantee a minimal 10-year service life without refrigerant leakage.

Solution: Our team partnered with the OEM to develop a custom r134a refrigerant hose featuring an advanced multi-layer barrier design (nylon core, EPDM intermediate, fiber reinforcement, and high-abrasion EPDM outer jacket). The hoses were supplied with specialized, vibration-dampening crimped fittings. Extensive testing, including impulse testing up to 200,000 cycles and permeation rates consistently below 2.5 g/yr·m, validated the design.

Outcome: The customized hose assemblies were integrated into their EV production line, meeting stringent performance criteria and contributing to the vehicles' overall energy efficiency and environmental compliance. The low permeation rate significantly reduced the need for refrigerant top-ups over the vehicle's lifetime, enhancing customer satisfaction and reducing warranty claims related to AC performance.

Case Study 2: Industrial HVAC Upgrade for a Pharmaceutical Plant

Client Profile: A large pharmaceutical manufacturing facility requiring precise temperature and humidity control in cleanroom environments.

Challenge: The plant's existing R134a-based chiller units were experiencing intermittent performance issues and higher-than-expected refrigerant loss, largely attributed to aging hose lines and fittings. Downtime for maintenance was highly costly due to stringent cleanroom protocols. The client needed a durable, corrosion-resistant solution that would minimize future leaks and maximize system uptime.

Solution: We provided a complete replacement package of custom-length r134a refrigerant charging hose assemblies, pre-fitted with stainless steel quick-connect couplers suitable for pharmaceutical cleanroom standards. The hoses featured enhanced EPDM outer covers for superior chemical and ozone resistance, coupled with high-pressure reinforcement. Batch-specific material certifications and performance data were provided to meet regulatory requirements.

Outcome: The upgrade resulted in a demonstrable reduction in refrigerant leakage by over 60% within the first year, significantly decreasing operational costs and environmental impact. The robust construction and chemical resistance of the new hoses ensured consistent HVAC performance, critical for maintaining product integrity in the cleanroom. The client reported a substantial increase in system reliability and a reduction in planned maintenance downtime for hose replacement.

Customer Feedback:

"The quality of the r134a hose from HoseQRT is consistently excellent. We've seen a marked improvement in the reliability of our mobile AC charging stations since switching to their products. The integrated gauges on their r134a recharge hose with gauge are also incredibly accurate, streamlining our field operations." - Senior HVAC Technician, Commercial Fleet Services.

Ensuring Trust: Certifications, Warranty, and Support

Trustworthiness in the B2B sector is built on transparency, quality assurance, and robust support systems. A reputable supplier of r134a refrigerant charging hose products will demonstrate these through comprehensive certifications and customer-centric policies.

Authoritative Certifications and Standards:

- ISO 9001:2015 Certification: This internationally recognized standard for quality management systems ensures that our manufacturing processes consistently meet customer and regulatory requirements, driving continuous improvement.

- SAE J2064 Compliance: Our automotive R134a hoses are designed and tested to meet or exceed the Society of Automotive Engineers (SAE) J2064 standard, ensuring suitability for automotive air conditioning applications.

- SAE J2888 Compliance: Specifically for refrigerant charging hoses, adherence to SAE J2888 guarantees safety and performance for technicians, preventing refrigerant loss and ensuring accurate charging procedures.

- CE Marking: Products intended for sale within the European Economic Area (EEA) comply with CE directives, affirming they meet high safety, health, and environmental protection requirements.

- RoHS Compliance: Commitment to restricting hazardous substances in electrical and electronic equipment, promoting environmental responsibility.

Our partnerships with leading clients across various sectors for over 20 years underscore our proven track record in delivering high-performance fluid transfer solutions.

Warranty Commitments and Quality Assurance:

We stand behind the quality of our R134a hoses with a comprehensive warranty against manufacturing defects. Typical warranty periods range from 1 to 3 years, reflecting our confidence in product durability and performance under specified operating conditions. Each product undergoes stringent multi-point inspection before shipment.

Lead Time and Fulfillment:

- Standard Orders: Typically 7-14 business days, depending on volume and current production schedules.

- Customized Solutions: Lead times for custom orders may vary from 3-6 weeks, subject to complexity and material sourcing, with clear communication at every stage.

- Expedited Shipping: Available upon request, with associated costs, to meet urgent project deadlines.

- Global Logistics: We leverage an efficient global logistics network to ensure timely and secure delivery worldwide.

Dedicated Customer Support:

Our commitment extends beyond product delivery. We provide expert technical support for product selection, installation guidance, and troubleshooting. Our dedicated customer service team is available via phone, email, and online inquiry to address any queries or concerns promptly and professionally. We believe in building lasting relationships through responsive and knowledgeable support.

Frequently Asked Questions (FAQ)

- Q1: What is the primary difference between an R134a refrigerant hose and a hose for other refrigerants?

- A: The primary difference lies in the inner tube material's compatibility and permeation characteristics. R134a hoses, particularly the inner barrier layer, are specifically engineered to resist the aggressive properties of R134a refrigerant and its associated PAG/POE oils, ensuring minimal permeation and chemical degradation. Hoses for other refrigerants (e.g., R12, R1234yf) have different material requirements.

- Q2: How often should an R134a charging hose be replaced?

- A: The replacement interval depends on usage frequency, operating conditions, and material quality. For professional workshop use, industry best practice often suggests inspection every 12-24 months and replacement every 3-5 years, or immediately if any signs of wear, cracking, kinking, or leakage are observed. Premium hoses offer longer service lives.

- Q3: Can I use an R134a recharge hose with gauge for R1234yf systems?

- A: No, it is strongly advised against. R1234yf systems use different fittings (to prevent cross-contamination) and require hoses specifically designed for the unique properties of R1234yf, which is mildly flammable and has different permeation characteristics. Using an R134a hose could lead to leaks, system damage, or safety hazards. Always use the correct hose type for the refrigerant being handled.

- Q4: What standards should an AC manifold gauge set R134a comply with?

- A: An AC manifold gauge set for R134a should comply with SAE J2888 for the charging hoses, which specifies minimum performance for refrigerant charging and recovery hoses, including permeation rates and pressure ratings. The gauges themselves should be accurate and calibrated to industry standards, typically with a class 1.6 accuracy rating or better. Ensure fittings are appropriate for R134a (e.g., specific quick couplers).

- Q5: How do I ensure minimal refrigerant loss during charging or recovery?

- A: Use high-quality, low-permeation r134a refrigerant charging hose with secure, leak-proof fittings (e.g., quick couplers with integrated shut-off valves). Always purge air from hoses before connecting to the system. Employ an efficient recovery machine. Regularly inspect hoses and fittings for wear, cracks, or damage, and replace as needed. Proper training and adherence to service procedures are also crucial.

Conclusion

The r134a refrigerant charging hose is far more than a simple conduit; it is a meticulously engineered component critical to the safety, efficiency, and environmental compliance of modern HVAC/R systems. For B2B stakeholders, understanding the technical specifications, rigorous manufacturing processes, and comprehensive advantages of premium hoses is essential for making informed procurement decisions. By prioritizing quality, adherence to international standards, and robust supplier support, businesses can ensure optimal system performance, minimize operational costs, and uphold their commitment to environmental stewardship in an evolving industry landscape.

References

- SAE International. (2019). SAE J2064: R134a (HFC-134a) Refrigerant Automotive Air Conditioning Hose. Retrieved from www.sae.org

- SAE International. (2018). SAE J2888: Refrigerant Charging and Recovery Hoses for Mobile Air Conditioning Systems. Retrieved from www.sae.org

- International Organization for Standardization. (2013). ISO 1307: Rubber and plastics hoses and hose assemblies — Rubber- or plastics-covered braided textile-reinforced hydraulic type — Dimensions and tolerancing of lengths. Retrieved from www.iso.org

- U.S. Environmental Protection Agency (EPA). (Current year). Section 609 of the Clean Air Act: Motor Vehicle Air Conditioning (MVAC) Servicing. Retrieved from www.epa.gov

- ASHRAE Handbook. (2020). Refrigeration. American Society of Heating, Refrigerating and Air-Conditioning Engineers. Retrieved from www.ashrae.org

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightЖаңалықтарNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapЖаңалықтарNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionЖаңалықтарNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableЖаңалықтарNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableЖаңалықтарNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableЖаңалықтарNov.10,2025

R134a Refrigerant Charging Hose with Gauge | Easy AC Recharge

Navigating the Landscape of R134a Refrigerant Charging Hose Technology

In the intricate world of heating, ventilation, air conditioning, and refrigeration (HVAC/R), the integrity and performance of every component are paramount. Among these, the r134a refrigerant charging hose stands as a critical link, enabling safe and efficient transfer of refrigerant in various systems. As a professional B2B content strategist, we understand that decision-makers in automotive, industrial, and commercial sectors demand precision, reliability, and technical superiority. This article provides an in-depth exploration of this essential component, addressing industry trends, technical specifications, application scenarios, and the comprehensive advantages offered by leading manufacturers.

The global market for automotive and industrial air conditioning components is experiencing robust growth, driven by increasing vehicle production, stricter environmental regulations, and the ongoing demand for efficient cooling solutions. The transition from older refrigerants to R134a and subsequently to newer, lower Global Warming Potential (GWP) alternatives has placed a renewed focus on hose material compatibility, leak prevention, and durability. Products such as the r134a refrigerant hose and the specialized r134a recharge hose with gauge are at the forefront of this evolution, designed to meet the rigorous demands of modern systems. Understanding the nuances of an ac manifold gauge set r134a further underscores the need for high-quality, reliable hose connections for accurate diagnostics and servicing.

Technical Deep Dive: The R134a Refrigerant Charging Hose

Structure and Materials Science

A high-performance r134a refrigerant charging hose is engineered with a multi-layered structure to ensure optimal performance, durability, and minimal refrigerant permeation. Typically, it comprises three main layers:

- Ішкі түтік: Crafted from specialized synthetic rubbers like Chloroprene (CR) or Ethylene Propylene Diene Monomer (EPDM), or increasingly, from barrier materials like Nylon (PA) or Thermoplastic Elastomers (TPE). These materials are chosen for their excellent resistance to R134a refrigerant, PAG/POE oils, and their very low permeation rates, which is crucial for maintaining system efficiency and environmental compliance.

- Reinforcement Layer: This critical layer provides the hose's structural integrity and pressure resistance. It typically consists of high-tensile synthetic fiber braids (e.g., polyester or aramid fibers) or spiral-wound layers, engineered to withstand high working pressures and prevent kinking.

- Outer Cover: Made from weather-resistant synthetic rubber (often EPDM or CR), this layer protects the inner layers from external elements such as abrasion, UV radiation, ozone, chemicals, and extreme temperatures, ensuring a prolonged service life.

Key Parameters and Performance Metrics

When selecting an r134a refrigerant hose, critical performance metrics must be considered:

- Working Pressure: Typically ranges from 350 PSI (2.4 MPa) for standard applications up to 800 PSI (5.5 MPa) for high-pressure lines. Burst pressure is often 4-5 times the working pressure.

- Температура диапазоны: Standard hoses are designed for -30°C to +110°C (-22°F to +230°F), with specialized hoses capable of wider ranges.

- Permeation Rate: Measured in grams per year per meter (g/yr·m) or similar units, this indicates the amount of refrigerant escaping through the hose wall. Lower rates are preferred and mandated by standards like SAE J2064 for automotive use.

- Minimum Bend Radius: Essential for installation in confined spaces, indicating the tightest curve the hose can form without kinking or compromising performance.

- Fittings Compatibility: Hoses must be compatible with standard R134a fittings (e.g., SAE J2888 compliant fittings) to ensure leak-proof connections.

Product Specification Table: R134a Refrigerant Charging Hose (Example)

| Parameter | Техникалық сипаттама | Standard (e.g., SAE J2064, ISO 1307) |

|---|---|---|

| Inner Tube Material | Barrier Nylon/EPDM/CR | SAE J2064 Type C, Class II |

| Reinforcement | High-tensile Polyester Fiber Braid | ISO 1307 |

| Outer Cover Material | EPDM/CR, Abrasion & Ozone Resistant | SAE J2064 |

| Жұмыс қысымы | 500 PSI (3.45 MPa) | SAE J2064 |

| Жарылыс қысымы | 2500 PSI (17.25 MPa) | SAE J2064 |

| Temperature Range | -30°C to +110°C (-22°F to +230°F) | SAE J2064 |

| Permeation Rate | < 3.0 g/yr·m (R134a) | SAE J2064 |

| Inner Diameter (Typical) | 1/4" (6.3 mm) to 1/2" (12.7 mm) | ISO 1307 |

Manufacturing Process Flow

The manufacturing of a high-quality r134a hose involves a precise, multi-stage process, ensuring product integrity and performance:

- Material Preparation: Sourcing and quality inspection of raw materials – synthetic rubbers (EPDM, CR, NBR), nylon resins, polyester fibers, and steel for fittings.

- Inner Tube Extrusion: The innermost layer, crucial for refrigerant compatibility and low permeation, is extruded using advanced machinery. This forms a seamless tube of precise inner diameter and wall thickness.

- Reinforcement Application (Braiding/Spiraling): The extruded inner tube moves to braiding or spiraling machines where high-tensile synthetic fibers are intricately woven or wound around it. This process imparts the necessary burst strength and pressure resistance.

- Outer Cover Extrusion: A protective outer layer of weather-resistant synthetic rubber is then extruded over the reinforced core. This layer guards against environmental degradation, abrasion, and chemicals.

- Curing/Vulcanization: The entire hose assembly undergoes a curing process, often in steam autoclaves, to cross-link the rubber polymers. This gives the hose its final mechanical properties, flexibility, and resilience.

- Cutting and Fitting Assembly: Hoses are cut to specified lengths. Fittings, often precision-machined from brass or steel (CNC machining for high accuracy), are then crimped onto the hose ends using specialized crimping machines, ensuring a robust, leak-proof connection.

- Testing & Quality Control: Every batch undergoes rigorous testing:

- Pressure Testing: Hydrostatic burst pressure and impulse testing (e.g., to ISO 1307, SAE J2064 standards).

- Permeation Testing: To ensure minimal refrigerant leakage over time.

- Vacuum Testing: To verify integrity under vacuum conditions, essential for system evacuation.

- Flexibility & Kink Resistance: To ensure durability during installation and use.

- Temperature Cycling: To simulate real-world thermal stresses.

- Dimensional Checks: Inner/outer diameter, length, and fitting dimensions.

- Packaging & Dispatch: Finished hoses are cleaned, inspected, and packaged according to customer specifications, ready for distribution to various target industries, including petrochemical, metallurgy, and water supply & drainage, wherever precise fluid transfer is required. The expected service life, when properly maintained, can exceed 10 years in typical applications due to robust materials and stringent testing.

This meticulous process ensures that each charging hose delivers advantages such as energy saving through reduced refrigerant loss, superior corrosion resistance, and exceptional longevity even in demanding operational environments.

Application Scenarios and Technical Advantages

The versatility and reliability of the r134a refrigerant charging hose make it indispensable across a spectrum of industries. Its technical advantages directly translate into operational efficiencies and cost savings for businesses.

Key Application Areas:

- Automotive AC Systems (OEM & Aftermarket): From initial vehicle assembly lines to routine maintenance and repair shops, these hoses are essential for charging, evacuating, and testing automotive air conditioning systems. The increasing complexity of modern vehicles, including electric and hybrid models, demands hoses that can withstand diverse under-hood conditions.

- Commercial & Industrial HVAC/R: Large-scale refrigeration units, chillers, and industrial air conditioning systems in factories, data centers, and commercial buildings rely on robust r134a hose products for consistent performance and minimal downtime.

- Marine and Rail Transportation: Specialized HVAC/R systems in marine vessels and railway carriages require hoses that can endure vibrations, varying temperatures, and corrosive environments, ensuring passenger comfort and critical equipment operation.

- Refrigerant Recovery and Recycling Equipment: Environmental regulations mandate the proper recovery and recycling of refrigerants. High-quality charging hoses are integral to the safe and efficient operation of such equipment, often integrated into an ac manifold gauge set r134a.

Technical Advantages:

- Superior Permeation Resistance: Advanced barrier materials significantly reduce refrigerant loss, contributing to energy saving by maintaining optimal system charge and reducing the frequency of recharges. This also directly impacts environmental compliance.

- Exceptional Durability and Service Life: Multi-layered construction with robust reinforcement and an abrasion-resistant outer cover ensures extended operational life, even in harsh conditions, reducing replacement costs and maintenance downtime.

- Corrosion and Chemical Resistance: Engineered to resist degradation from refrigerants, oils, and common atmospheric chemicals, preserving the hose's structural integrity and preventing leaks over time.

- High-Pressure and Temperature Tolerance: Designed to safely handle the high pressures and extreme temperature fluctuations inherent in R134a systems, ensuring operational safety and reliability.

- Flexibility and Ease of Installation: Despite their robust construction, quality hoses maintain sufficient flexibility for easy routing and installation in tight spaces, minimizing installation time and effort.

- Safety Features: Many hoses, especially those designed as an r134a recharge hose with gauge, incorporate features like anti-blowback valves and ergonomic couplers for enhanced user safety during charging operations.

Vendor Comparison and Customized Solutions

Choosing the right supplier for r134a hose products is a strategic decision that impacts long-term operational efficiency and cost. Factors beyond mere price must be thoroughly evaluated by B2B buyers.

Key Considerations for Vendor Selection:

- Certifications and Standards Compliance: Verify adherence to international standards such as ISO 9001 (quality management), SAE J2064 (automotive A/C hose), SAE J2888 (refrigerant charging hose), and CE marking.

- Material Quality and Traceability: Enquire about the origin and specification of raw materials used. Reputable vendors offer full material traceability.

- Manufacturing Capabilities: Assess the vendor's production capacity, quality control procedures, and adoption of advanced manufacturing techniques (e.g., automated extrusion, precision crimping).

- Testing Protocols: Understand the in-house and third-party testing regimes for pressure, permeation, impulse, and temperature cycling.

- Lead Times and Logistics: Evaluate the vendor's ability to meet delivery schedules and their logistical support capabilities, especially for large or recurring orders.

- Technical Support and After-Sales Service: Access to expert technical assistance, application engineering support, and clear warranty terms are crucial for long-term partnerships.

Product Comparison: Standard vs. Premium R134a Hoses

| Feature | Standard R134a Hose | Premium R134a Hose (e.g., HoseQRT) |

|---|---|---|

| Inner Tube | EPDM/NBR | High-barrier Nylon/TPE + EPDM |

| Permeation Rate (R134a) | ~5-10 g/yr·m | < 3.0 g/yr·m (SAE J2064 compliant) |

| Жұмыс қысымы | Up to 350 PSI | Up to 800 PSI |

| Жарылыс қысымы | ~1400 PSI | ~3000-4000 PSI |

| Temperature Range | -20°C to +100°C | -30°C to +120°C |

| Abrasion Resistance | Moderate | High (Enhanced EPDM/CR) |

| Typical Service Life | 3-5 Years | 8-12 Years |

Customized Solutions:

Leading manufacturers offer extensive customization capabilities to meet specific project requirements:

- Length and Diameter: Hoses can be manufactured to precise lengths and inner diameters to fit unique system layouts.

- Fittings and Connectors: Customization includes a wide range of standard and specialized fittings (e.g., straight, 45°, 90° bends, quick-connect, ball valve) in various materials (brass, steel, aluminum) to ensure perfect compatibility with existing equipment or new designs. This is particularly relevant for an ac manifold gauge set r134a.

- Color Coding and Branding: Hoses can be color-coded for easy identification of different lines (e.g., high-pressure, low-pressure) or branded with company logos for private labeling.

- Specialized Outer Covers: For extremely abrasive or corrosive environments, custom outer covers with enhanced resistance (e.g., thermoplastic sheathing, polyurethane covers) can be provided.

- Integrated Features: Custom options might include integrating pressure sensors, temperature probes, or specialized valves directly into the hose assembly.

Real-World Application Case Studies & Customer Experience

The practical impact of high-quality r134a refrigerant charging hose solutions is best demonstrated through real-world applications and direct customer feedback.

Case Study 1: Automotive OEM Integration for Electric Vehicles

Client Profile: A major global automotive manufacturer specializing in electric vehicles (EVs).

Challenge: EVs require highly efficient and reliable thermal management systems, often integrating the battery cooling with the cabin AC. This demands hoses with extremely low permeation rates, superior vibration resistance, and compatibility with the specific dielectric properties of EV refrigerants and oils, operating under varied pressure pulses. The manufacturer sought a hose assembly that could guarantee a minimal 10-year service life without refrigerant leakage.

Solution: Our team partnered with the OEM to develop a custom r134a refrigerant hose featuring an advanced multi-layer barrier design (nylon core, EPDM intermediate, fiber reinforcement, and high-abrasion EPDM outer jacket). The hoses were supplied with specialized, vibration-dampening crimped fittings. Extensive testing, including impulse testing up to 200,000 cycles and permeation rates consistently below 2.5 g/yr·m, validated the design.

Outcome: The customized hose assemblies were integrated into their EV production line, meeting stringent performance criteria and contributing to the vehicles' overall energy efficiency and environmental compliance. The low permeation rate significantly reduced the need for refrigerant top-ups over the vehicle's lifetime, enhancing customer satisfaction and reducing warranty claims related to AC performance.

Case Study 2: Industrial HVAC Upgrade for a Pharmaceutical Plant

Client Profile: A large pharmaceutical manufacturing facility requiring precise temperature and humidity control in cleanroom environments.

Challenge: The plant's existing R134a-based chiller units were experiencing intermittent performance issues and higher-than-expected refrigerant loss, largely attributed to aging hose lines and fittings. Downtime for maintenance was highly costly due to stringent cleanroom protocols. The client needed a durable, corrosion-resistant solution that would minimize future leaks and maximize system uptime.

Solution: We provided a complete replacement package of custom-length r134a refrigerant charging hose assemblies, pre-fitted with stainless steel quick-connect couplers suitable for pharmaceutical cleanroom standards. The hoses featured enhanced EPDM outer covers for superior chemical and ozone resistance, coupled with high-pressure reinforcement. Batch-specific material certifications and performance data were provided to meet regulatory requirements.

Outcome: The upgrade resulted in a demonstrable reduction in refrigerant leakage by over 60% within the first year, significantly decreasing operational costs and environmental impact. The robust construction and chemical resistance of the new hoses ensured consistent HVAC performance, critical for maintaining product integrity in the cleanroom. The client reported a substantial increase in system reliability and a reduction in planned maintenance downtime for hose replacement.

Customer Feedback:

"The quality of the r134a hose from HoseQRT is consistently excellent. We've seen a marked improvement in the reliability of our mobile AC charging stations since switching to their products. The integrated gauges on their r134a recharge hose with gauge are also incredibly accurate, streamlining our field operations." - Senior HVAC Technician, Commercial Fleet Services.

Ensuring Trust: Certifications, Warranty, and Support

Trustworthiness in the B2B sector is built on transparency, quality assurance, and robust support systems. A reputable supplier of r134a refrigerant charging hose products will demonstrate these through comprehensive certifications and customer-centric policies.

Authoritative Certifications and Standards:

- ISO 9001:2015 Certification: This internationally recognized standard for quality management systems ensures that our manufacturing processes consistently meet customer and regulatory requirements, driving continuous improvement.

- SAE J2064 Compliance: Our automotive R134a hoses are designed and tested to meet or exceed the Society of Automotive Engineers (SAE) J2064 standard, ensuring suitability for automotive air conditioning applications.

- SAE J2888 Compliance: Specifically for refrigerant charging hoses, adherence to SAE J2888 guarantees safety and performance for technicians, preventing refrigerant loss and ensuring accurate charging procedures.

- CE Marking: Products intended for sale within the European Economic Area (EEA) comply with CE directives, affirming they meet high safety, health, and environmental protection requirements.

- RoHS Compliance: Commitment to restricting hazardous substances in electrical and electronic equipment, promoting environmental responsibility.

Our partnerships with leading clients across various sectors for over 20 years underscore our proven track record in delivering high-performance fluid transfer solutions.

Warranty Commitments and Quality Assurance:

We stand behind the quality of our R134a hoses with a comprehensive warranty against manufacturing defects. Typical warranty periods range from 1 to 3 years, reflecting our confidence in product durability and performance under specified operating conditions. Each product undergoes stringent multi-point inspection before shipment.

Lead Time and Fulfillment:

- Standard Orders: Typically 7-14 business days, depending on volume and current production schedules.

- Customized Solutions: Lead times for custom orders may vary from 3-6 weeks, subject to complexity and material sourcing, with clear communication at every stage.

- Expedited Shipping: Available upon request, with associated costs, to meet urgent project deadlines.

- Global Logistics: We leverage an efficient global logistics network to ensure timely and secure delivery worldwide.

Dedicated Customer Support:

Our commitment extends beyond product delivery. We provide expert technical support for product selection, installation guidance, and troubleshooting. Our dedicated customer service team is available via phone, email, and online inquiry to address any queries or concerns promptly and professionally. We believe in building lasting relationships through responsive and knowledgeable support.

Frequently Asked Questions (FAQ)

- Q1: What is the primary difference between an R134a refrigerant hose and a hose for other refrigerants?

- A: The primary difference lies in the inner tube material's compatibility and permeation characteristics. R134a hoses, particularly the inner barrier layer, are specifically engineered to resist the aggressive properties of R134a refrigerant and its associated PAG/POE oils, ensuring minimal permeation and chemical degradation. Hoses for other refrigerants (e.g., R12, R1234yf) have different material requirements.

- Q2: How often should an R134a charging hose be replaced?

- A: The replacement interval depends on usage frequency, operating conditions, and material quality. For professional workshop use, industry best practice often suggests inspection every 12-24 months and replacement every 3-5 years, or immediately if any signs of wear, cracking, kinking, or leakage are observed. Premium hoses offer longer service lives.

- Q3: Can I use an R134a recharge hose with gauge for R1234yf systems?

- A: No, it is strongly advised against. R1234yf systems use different fittings (to prevent cross-contamination) and require hoses specifically designed for the unique properties of R1234yf, which is mildly flammable and has different permeation characteristics. Using an R134a hose could lead to leaks, system damage, or safety hazards. Always use the correct hose type for the refrigerant being handled.

- Q4: What standards should an AC manifold gauge set R134a comply with?

- A: An AC manifold gauge set for R134a should comply with SAE J2888 for the charging hoses, which specifies minimum performance for refrigerant charging and recovery hoses, including permeation rates and pressure ratings. The gauges themselves should be accurate and calibrated to industry standards, typically with a class 1.6 accuracy rating or better. Ensure fittings are appropriate for R134a (e.g., specific quick couplers).

- Q5: How do I ensure minimal refrigerant loss during charging or recovery?

- A: Use high-quality, low-permeation r134a refrigerant charging hose with secure, leak-proof fittings (e.g., quick couplers with integrated shut-off valves). Always purge air from hoses before connecting to the system. Employ an efficient recovery machine. Regularly inspect hoses and fittings for wear, cracks, or damage, and replace as needed. Proper training and adherence to service procedures are also crucial.

Conclusion

The r134a refrigerant charging hose is far more than a simple conduit; it is a meticulously engineered component critical to the safety, efficiency, and environmental compliance of modern HVAC/R systems. For B2B stakeholders, understanding the technical specifications, rigorous manufacturing processes, and comprehensive advantages of premium hoses is essential for making informed procurement decisions. By prioritizing quality, adherence to international standards, and robust supplier support, businesses can ensure optimal system performance, minimize operational costs, and uphold their commitment to environmental stewardship in an evolving industry landscape.

References

- SAE International. (2019). SAE J2064: R134a (HFC-134a) Refrigerant Automotive Air Conditioning Hose. Retrieved from www.sae.org

- SAE International. (2018). SAE J2888: Refrigerant Charging and Recovery Hoses for Mobile Air Conditioning Systems. Retrieved from www.sae.org

- International Organization for Standardization. (2013). ISO 1307: Rubber and plastics hoses and hose assemblies — Rubber- or plastics-covered braided textile-reinforced hydraulic type — Dimensions and tolerancing of lengths. Retrieved from www.iso.org

- U.S. Environmental Protection Agency (EPA). (Current year). Section 609 of the Clean Air Act: Motor Vehicle Air Conditioning (MVAC) Servicing. Retrieved from www.epa.gov

- ASHRAE Handbook. (2020). Refrigeration. American Society of Heating, Refrigerating and Air-Conditioning Engineers. Retrieved from www.ashrae.org

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightЖаңалықтарNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapЖаңалықтарNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionЖаңалықтарNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableЖаңалықтарNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableЖаңалықтарNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableЖаңалықтарNov.10,2025