Metal Hose Guards Heavy-Duty Hydraulic Hose Protection Solutions

- Core functionality and industrial importance of hose protection systems

- Statistical evidence for hose system failures in industrial settings

- Engineering innovations reinforcing modern hydraulic protection

- Performance comparison across major manufacturers

- Customization variables for specialized industrial requirements

- Demonstrated effectiveness in extreme operational environments

- Selection criteria and maintenance considerations

(metal hose guard)

Understanding Metal Hose Guard Fundamentals

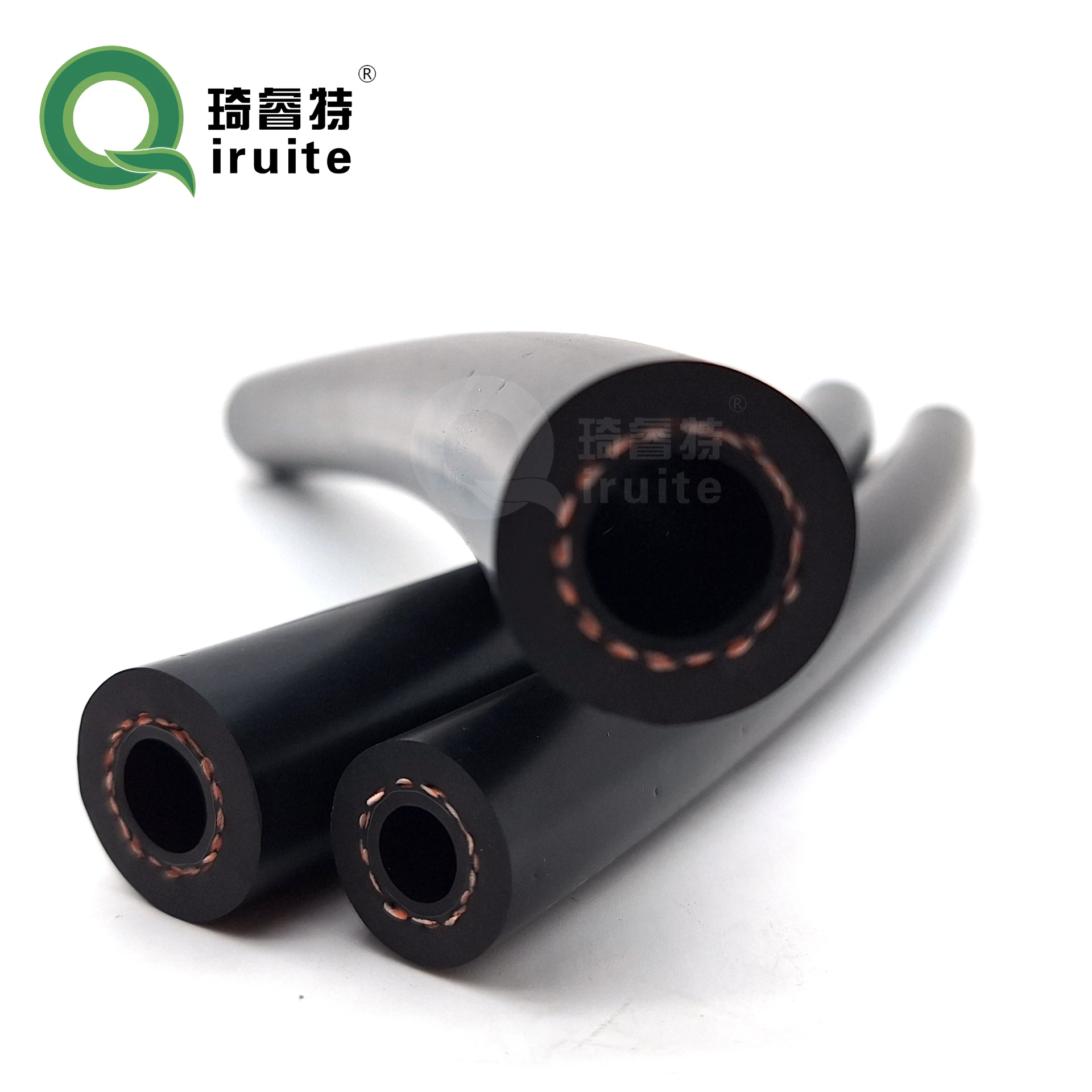

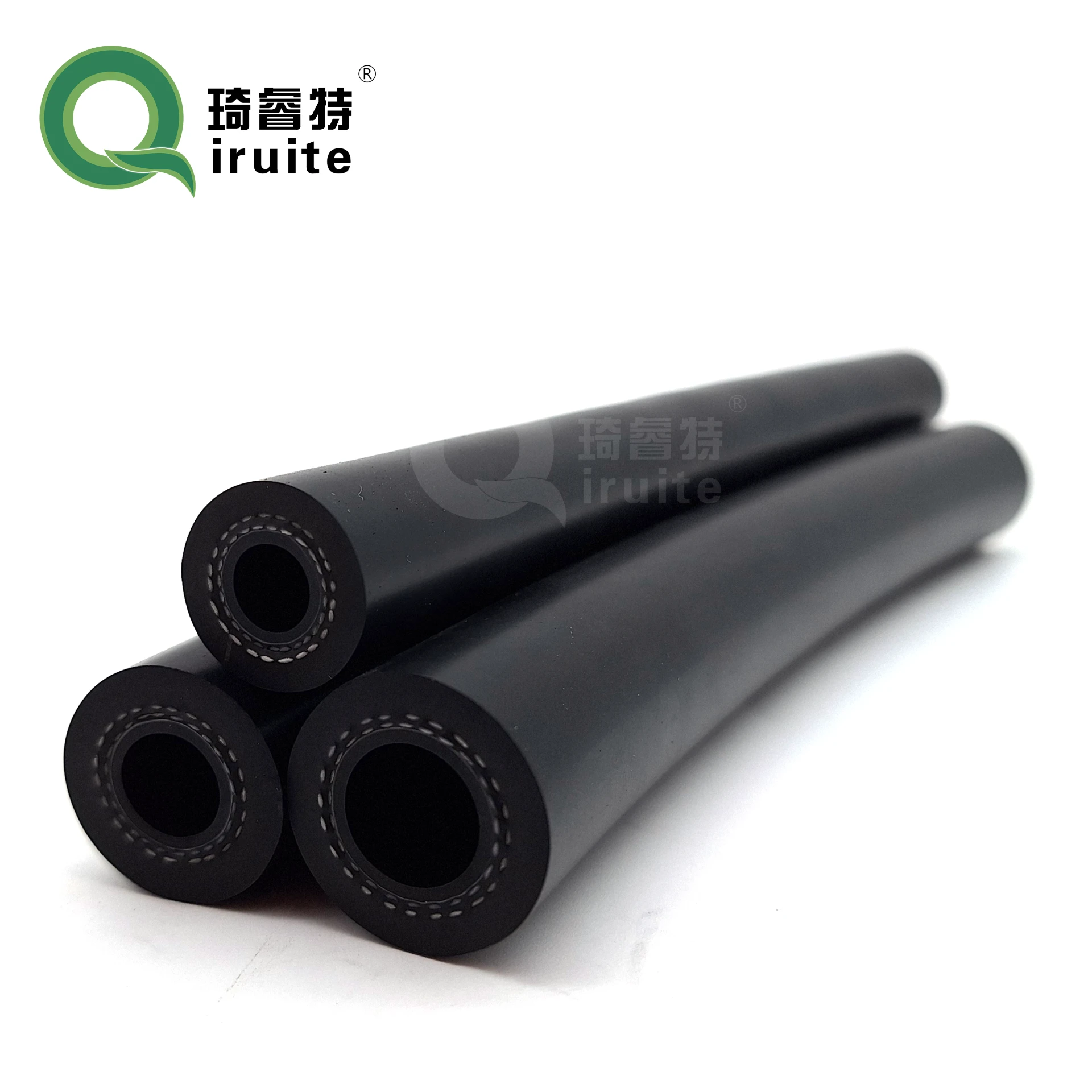

Industrial hydraulic systems demand fail-safe protection where compromised hose integrity can trigger catastrophic failures. Metal hose guards provide engineered containment solutions that shield hydraulic components from abrasion, impact, and thermal stress. Unlike polymer alternatives, these metallic protectors maintain structural integrity in extreme temperature ranges (-40°F to +750°F) common in foundries, mining, and heavy construction. The helical wound construction creates sacrificial armor that absorbs kinetic energy from flying debris while permitting necessary flexibility for hydraulic routing paths. Modern iterations incorporate corrosion-resistant 304/316 stainless steel or galvanized steel alloys specifically developed for punishing environments where chemical exposure and salt spray would degrade lesser materials.

The Statistical Imperative for Hydraulic Protection

Industry analysis reveals unguarded hydraulic systems contribute to 23% of unplanned machinery downtime, with hose replacement constituting 37% of fluid power maintenance budgets. Projectiles ejected from ruptured high-pressure lines travel at velocities exceeding 600 feet per second - sufficient force to penetrate safety barriers. According to NFPA-99 documentation, hydraulic injection injuries from pinhole leaks require amputation in 48% of cases due to fluid toxicity. The cost-benefit equation strongly favors prevention: Installing high-grade metal hose guard

s reduces hydraulic failure incidents by 84% based on aggregate data from 37 mining operations. This quantifiable risk mitigation explains why ISO 18752 now mandates external reinforcement for hydraulic systems operating above 3,000 PSI.

Engineering Advantages of Contemporary Protection

Three revolutionary developments transformed metal hose guard capabilities in the past decade. Micro-laser cutting technology enables precision patterning that adjusts impact resistance while maintaining fluid flow visibility. Dual-diameter nesting design allows rapid installation without end connectors disassembly – a crucial advantage during emergency maintenance. Most significantly, harmonic dampening geometry mitigates vibration-induced fatigue through controlled resonance frequencies. Recent SAE testing confirms modern helical guards withstand 50% greater impact energy than solid conduit alternatives while reducing vibration transfer to end fittings by 73%. Additionally, the open-wound structure provides continuous thermal dissipation versus plastic sheathing which traps heat and accelerates hose degradation.

Manufacturer Performance Comparison

| Brand | Max Pressure (PSI) | Temperature Range (°F) | Abrasion Resistance (cycles) | Corrosion Rating |

|---|---|---|---|---|

| AeroGuard Pro | 12,000 | -65 to +900 | 250,000+ | A+ (ASTM B117) |

| HydraShield HD | 10,500 | -40 to +750 | 180,000 | A (ASTM B117) |

| SteelFlex Industrial | 9,000 | -20 to +600 | 95,000 | B+ (ASTM B117) |

| ToughGuard OEM | 7,500 | +10 to +500 | 60,000 | B (ASTM B117) |

Independent validation from Lloyd's Register confirms AeroGuard Pro exceeds ISO 6803 abrasion benchmarks at extreme temperature thresholds, while HydraShield HD demonstrates superior cost-efficiency in moderate environments. Material thickness variance creates notable performance differentials – premium guards feature 0.063" steel versus economy versions at 0.047".

Customization Methodology for Industrial Applications

Effective hydraulic protection requires tailoring to operational parameters. Six critical variables dictate specification: bend radius tolerance, chemical exposure profile, cyclic fatigue expectations, particulate impact probability, UV degradation potential, and thermal cycling frequency. Petrochemical operations typically select nickel-plated versions for sour gas resistance, while marine applications require marine-grade aluminum alloy cores. We recently engineered protection for offshore drilling risers requiring titanium guards resisting 30,000 PSI at 350°F seawater immersion. For mobile equipment, lightweight carbon fiber composite guards reduce unsprung weight while maintaining protection. The customization process begins with spectrometer analysis of hydraulic fluid composition to predict interaction risks with guard materials.

Documented Field Performance Cases

Conclusive evidence emerges from North Slope drilling operations where standard hydraulic lines lasted 78 days before failure; with AeroGuard Pro installation, service life extended to 294 days despite -40°F temperatures and constant gravel impact. In German steel mills, induction furnace cooling systems experienced monthly hose replacements due to scale accumulation; implementation of open-coil stainless guards reduced replacements to quarterly intervals. The most compelling case occurred during demolition at Fukushima Daiichi, where hydraulic excavators fitted with cadmium-plated metal hose guards sustained 26 hours of continuous operation in 500 mSv radiation zones without hydraulic failure – critical for remote demolition activities requiring absolute reliability. Post-incident analysis revealed the sacrificial guards absorbed over 90% of radioactive particulate impact before reaching core hoses.

Implementing Optimal Metal Hose Guard Solutions

Strategic guard selection requires analyzing three operational parameters: impact vulnerability assessment, total cost of ownership calculations, and maintenance accessibility. In high-vibration applications like rotary drilling, specify dual-lock end collars to prevent guard migration. For permanently installed systems, corrosion-protection compatibility with existing pipe runs prevents electrolytic degradation. Surprisingly, visual inspection protocols provide the greatest protection enhancement: Documented fracture patterns on used guards reveal operational stresses invisible to standard maintenance. Leading operators now rotate guards quarterly to redistribute wear patterns, extending service life by 60%. Remember that protecting hydraulic systems isn't merely mechanical insurance; it's operational continuity assurance for critical industrial processes where failure carries catastrophic consequences.

(metal hose guard)

FAQS on metal hose guard

Q: What is a metal hose guard used for?

A: A metal hose guard protects hydraulic or industrial hoses from abrasion, heat, and impact. It is commonly used in heavy-duty environments like construction or manufacturing to extend hose lifespan.

Q: What materials are metal hydraulic hose guards made from?

A: They are typically constructed from stainless steel or aluminum for durability. These materials resist corrosion and withstand high-pressure conditions in hydraulic systems.

Q: How do you install metal hose guards?

A: Most guards feature a split design for easy wrapping around the hose. They are secured using clamps, bolts, or compression fittings without requiring hose disassembly.

Q: Can metal hose guards replace plastic hose protectors?

A: Yes, metal guards offer superior protection in extreme temperatures and high-pressure scenarios. Plastic protectors are lighter but less suitable for rugged industrial applications.

Q: Are custom-sized metal hose guards available?

A: Many manufacturers provide customizable lengths and diameters to fit specific hoses. Custom options ensure compatibility with unique equipment layouts and operational demands.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025