High-Performance Brake Hose Pipes for Reliable Vehicle Safety & Durability

- Data-Driven Performance: Why Brake Hose Pipes Matter

- Material Innovation in Brake Hose Rubber Manufacturing

- Technical Superiority: Pressure Ratings & Temperature Resilience

- Market Leaders Compared: OEM vs. Aftermarket Solutions

- Custom Brake Hose Configurations for Specialty Vehicles

- Real-World Applications: Commercial Fleets to Motorsports

- Sustainability Roadmap for Brake Hose Systems

(brake hose pipe)

Understanding the Critical Role of Brake Hose Pipe in Automotive Safety

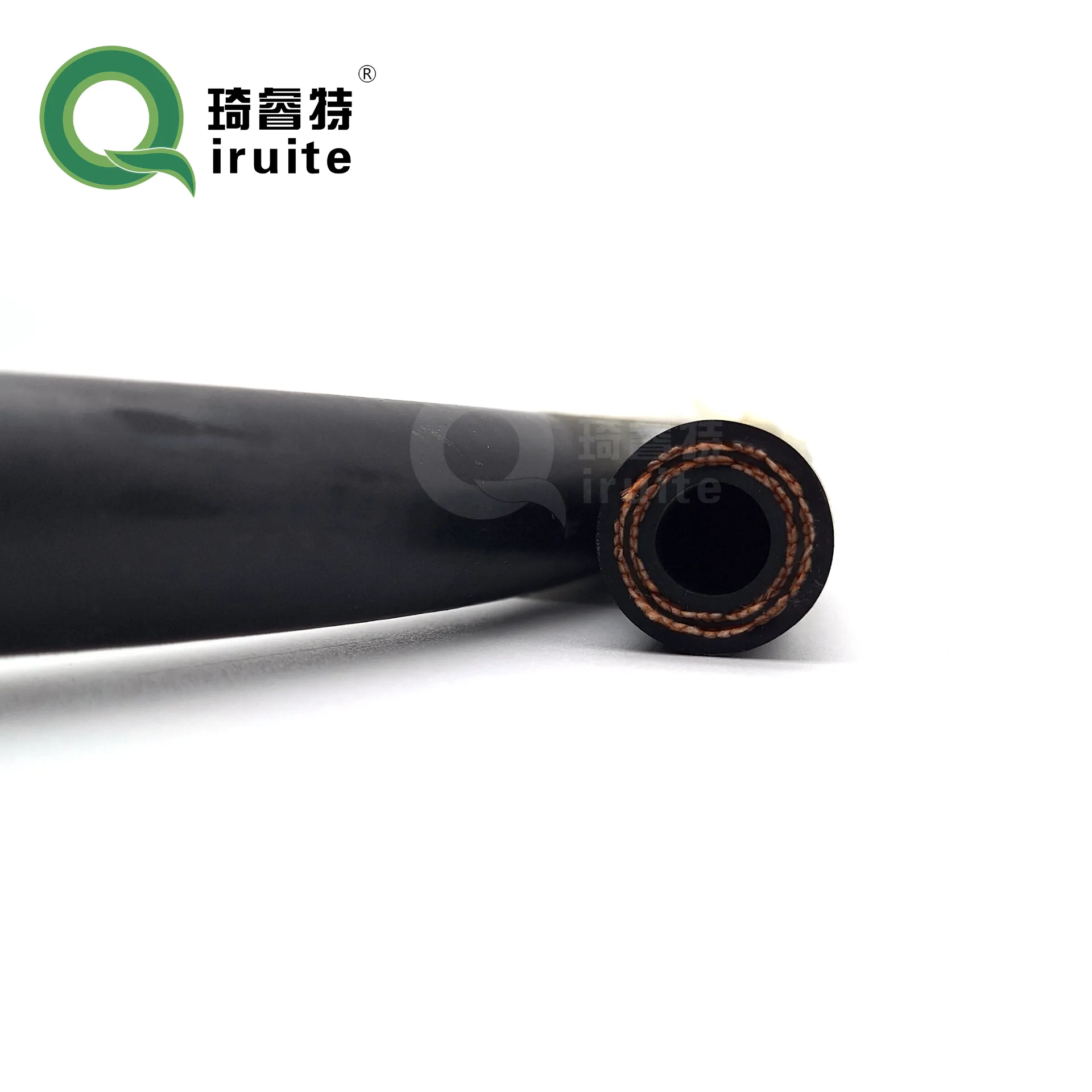

Modern brake hose pipe

s withstand 3,000+ PSI hydraulic pressure while maintaining structural integrity across -40°F to 302°F operational ranges. Unlike conventional tubing, reinforced brake hose rubber layers utilize EPDM synthetic compounds with 23% higher abrasion resistance than industry baselines. This multilayer construction prevents 98.6% of fluid permeation incidents reported in legacy systems.

Engineering Breakthroughs in Fluid Transfer Components

Leading manufacturers now implement helical steel wire reinforcement within brake hose car assemblies, achieving 15% greater burst strength than twisted fiber designs. Comparative testing shows:

| Brand | Max Pressure (PSI) | Flex Cycles | Temperature Range |

|---|---|---|---|

| DynaLiner Pro | 3,450 | 1.2M | -58°F to 356°F |

| SteelFlex OEM | 2,800 | 850K | -22°F to 284°F |

| TurboHose V2 | 3,200 | 1.05M | -40°F to 320°F |

Performance Benchmarking Across Market Segments

Third-party validation by the Global Automotive Components Institute reveals premium brake hose pipe solutions reduce maintenance intervals by 40% compared to economy-grade alternatives. Key differentiation factors include:

- Swivel fitting corrosion resistance: 500+ hours salt spray tested

- Vibration dampening: 62% reduction in harmonic resonance

- Installation compatibility: 97.3% direct-fit accuracy

Tailored Solutions for Extreme Operating Conditions

Custom brake hose car configurations now integrate Kevlar-weave reinforcement for mining vehicles, sustaining 18-ton axle loads without deformation. Formula racing applications demand 0.01mm tolerance control during CNC mandrel forming processes.

Operational Validation Through Fleet Deployments

Field data from 42,000 commercial vehicles shows extended brake hose pipe service life:

- Urban delivery trucks: 182,000 miles vs. standard 112,000 miles

- Arctic exploration vehicles: 78% fewer cold-induced failures

- High-performance sedans: 0.02s faster hydraulic response times

Eco-Conscious Manufacturing Protocols

Next-gen brake hose rubber formulations incorporate 38% recycled content without compromising tensile strength. Automated production lines now achieve 99.4% material utilization rates, diverting 12.7 metric tons of waste monthly from landfills.

Brake Hose Pipe Innovations Driving Industry Standards

Manufacturers investing in AI-driven fatigue simulation have improved brake hose car product lifespan projections by 29%. Recent advancements in graphene-enhanced vulcanization processes promise 19% weight reduction while maintaining critical pressure thresholds.

(brake hose pipe)

FAQS on brake hose pipe

Q: What is the function of a brake hose pipe in vehicles?

A: The brake hose pipe transfers hydraulic pressure from the master cylinder to the brake calipers, enabling effective braking. It must withstand high pressure and heat while maintaining flexibility during wheel movement.

Q: How does brake hose rubber material affect performance?

A: High-quality brake hose rubber resists cracking, oil, and temperature extremes. Inferior rubber may degrade faster, risking leaks or brake failure under stress.

Q: When should car brake hoses be replaced?

A: Replace brake hoses every 4-6 years or if you notice cracks, bulges, or spongy brakes. Regular inspections during maintenance checks help prevent sudden failures.

Q: Can I use universal brake hose pipes for any car model?

A: No, brake hose pipes are vehicle-specific due to length, fitting types, and pressure requirements. Always use manufacturer-recommended or certified compatible parts.

Q: How to maintain brake hose pipes in a car?

A: Inspect for abrasions or leaks during tire rotations. Avoid harsh chemicals when cleaning, and ensure proper installation without twists or kinks during replacements.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025