R134a Refrigerant Charging Hose | Easy AC Recharge & Gauge

Navigating the Landscape of R134a Refrigerant Charging Hoses

In the intricate world of thermal management and refrigeration, the integrity and performance of every component are paramount. Among these, the r134a refrigerant charging hose stands as a critical conduit, directly impacting system efficiency, safety, and environmental compliance. Designed for precise and secure transfer of R134a refrigerant, these hoses are indispensable in automotive air conditioning, HVAC systems, and various industrial refrigeration applications.

The global market for automotive and industrial refrigerants, while evolving towards new, lower Global Warming Potential (GWP) alternatives like HFO-1234yf, continues to see substantial demand for R134a. This sustained usage necessitates high-quality, reliable R134a refrigerant hose solutions that minimize leakage, ensure operational safety, and extend system service life. Industry trends indicate a growing emphasis on enhanced material science, advanced manufacturing processes, and stringent testing protocols to meet escalating performance expectations and environmental regulations.

The market for r134a refrigerant charging hose is driven by the vast installed base of R134a-dependent systems, particularly in the automotive sector. As vehicles age, maintenance and recharging become more frequent, creating consistent demand for robust and accurate R134a hose products. This section will delve into the technical intricacies, application diversity, and the rigorous standards defining the next generation of these essential components.

The Precision Engineering Behind Every R134a Refrigerant Charging Hose

Manufacturing Process: A Symphony of Materials and Methodology

The production of a high-performance r134a refrigerant charging hose is a sophisticated multi-stage process, meticulously designed to achieve superior chemical resistance, low permeation, and exceptional mechanical durability. This process flow ensures that each R134a hose meets or exceeds demanding industry standards such as SAE J2064 and ISO 9001:2015.

- Material Selection: The foundation of quality begins with carefully chosen materials. The inner tube, critical for chemical resistance, is typically made from highly specialized synthetic rubbers like Hydrogenated Nitrile Butadiene Rubber (HNBR) or Ethylene Propylene Diene Monomer (EPDM), often incorporating a Polyamide (PA) or Nylon barrier layer to significantly reduce refrigerant permeation. The reinforcement layer usually consists of a high-tensile synthetic fiber braid (e.g., polyester or aramid) for pressure resistance, while the outer cover is crafted from weather-resistant EPDM or Chloroprene Rubber (CR) to protect against abrasion, ozone, and UV radiation.

- Inner Tube Extrusion: The innermost layer is precisely extruded to ensure uniform wall thickness and a smooth inner surface, crucial for laminar flow and minimizing pressure drop.

- Barrier Layer Application: For ultra-low permeation, a thin, robust barrier layer (e.g., Nylon 6 or Nylon 11) is applied over the inner tube, often through a co-extrusion process, forming a virtually impermeable shield against refrigerant escape.

- Reinforcement Winding: High-strength textile fibers are spirally wound or braided around the barrier layer. This step, akin to forging in metalworking, provides the hose with its burst and working pressure capabilities, determining its ability to withstand system pressures without deformation or failure.

- Outer Cover Extrusion: The protective outer layer is then extruded over the reinforced core, providing environmental protection and mechanical durability.

- Vulcanization/Curing: The entire hose assembly undergoes a controlled curing process at specific temperatures and pressures. This "baking" process cross-links the rubber compounds, imparting the final physical properties, elasticity, and chemical resistance to the hose.

- Cutting and Assembly: Hoses are cut to specified lengths, and specialized fittings (e.g., 90-degree service couplers, ball valve fittings) are crimped onto the ends using precision CNC machining. The crimping process is critical to ensure a leak-proof connection that can withstand high pressures and vibrations.

- Rigorous Testing Standards: Every batch undergoes extensive testing, including burst pressure tests (typically exceeding 5 times the working pressure), vacuum tests, leak detection (helium leak test), impulse tests (simulating pressure cycles), and permeation tests (to ensure refrigerant retention). These adhere to international standards like ISO 14001, ANSI/ASHRAE, and specific automotive OEM requirements.

This meticulous manufacturing process ensures a service life often exceeding 10 years in typical applications, making these hoses ideal for target industries such as automotive manufacturing, industrial HVAC, petrochemical processing, and specialized vehicle AC systems where energy saving (through minimal leakage) and corrosion resistance are critical performance advantages.

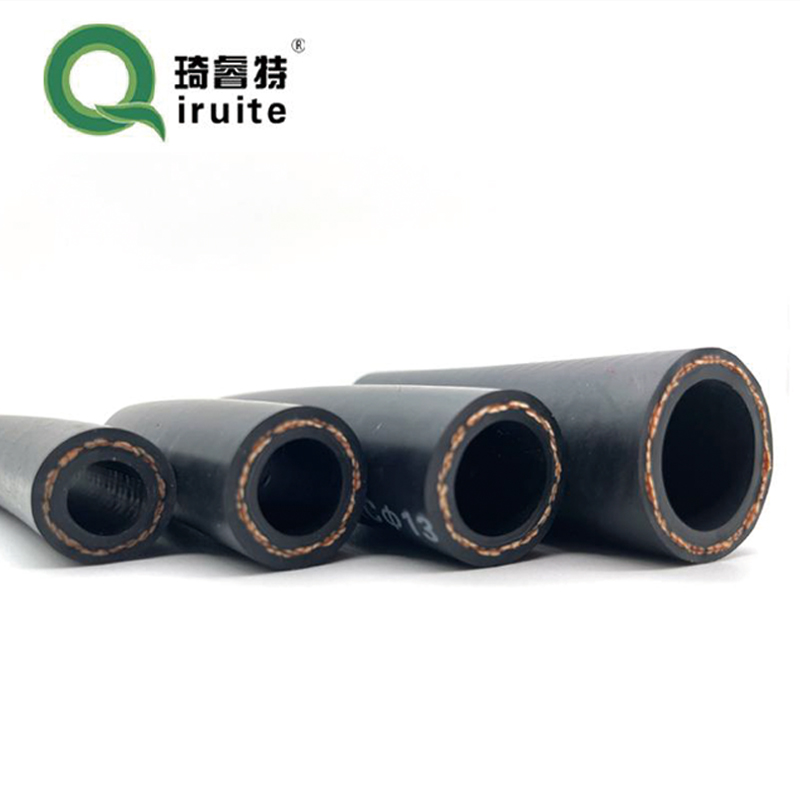

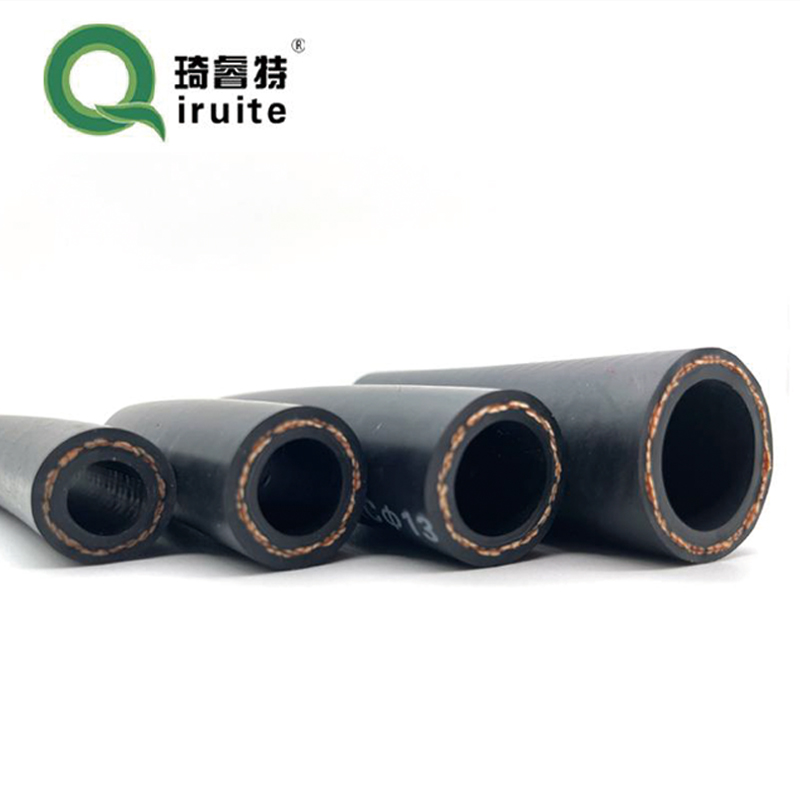

Figure 1: Cross-section detail of an advanced R134a refrigerant hose showcasing multi-layer construction.

Technical Specifications and Performance Excellence

The performance of an r134a refrigerant charging hose is defined by a comprehensive set of technical parameters, each optimized to ensure reliability and efficiency under diverse operating conditions. Understanding these specifications is crucial for engineers and procurement specialists.

Key Specifications for R134a Refrigerant Hoses

These parameters underscore the engineering sophistication involved. For instance, the low permeation rate is a direct result of the advanced barrier layer technology, minimizing refrigerant loss and contributing to both environmental protection and system operational efficiency. The robust burst pressure rating provides a critical safety margin, preventing catastrophic failures even under transient pressure spikes.

Technical Advantages: The Edge in Performance and Reliability

Choosing the right r134a refrigerant charging hose is not merely about functional compatibility; it's about leveraging technical advantages that translate into long-term cost savings, enhanced system performance, and superior operational safety. Our advanced hoses embody several key benefits:

- Ultra-Low Refrigerant Permeation: Utilizing multi-layer barrier technology (e.g., Nylon 11), our hoses significantly reduce refrigerant leakage, leading to fewer recharges, lower environmental impact, and consistent system cooling performance. This directly contributes to energy saving by maintaining optimal charge levels.

- Exceptional Durability and Longevity: Constructed with high-tensile strength reinforcement layers and weather-resistant outer covers, these hoses offer superior resistance to abrasion, ozone, UV, and harsh automotive/industrial chemicals. This robust design extends the service life dramatically, reducing replacement frequency.

- High Pressure and Temperature Tolerance: Engineered to withstand the demanding pressures and temperature fluctuations inherent in R134a systems, ensuring reliable operation even in extreme climatic conditions.

- Optimized Flexibility: Despite their robust construction, the hoses maintain excellent flexibility, facilitating easier installation and routing in confined spaces without compromising integrity or creating kinks.

- Corrosion Resistance: Material choices for fittings (e.g., brass, stainless steel) and the hose's outer cover are selected for superior corrosion resistance, ensuring long-term aesthetic and functional integrity in various environments, including exposure to road salts and industrial chemicals.

- Compliance with Global Standards: Adherence to international standards like SAE J2064 guarantees that our products meet the highest benchmarks for safety, performance, and environmental responsibility, essential for global market penetration.

These advantages make our r134a refrigerant charging hose a preferred choice for applications demanding peak performance and unwavering reliability, where failure is not an option.

Diverse Application Scenarios: Where Performance Matters

The versatility and robust design of the r134a refrigerant charging hose allow it to be deployed across a wide spectrum of industries and applications. Its reliability is critical in ensuring the efficient and safe operation of R134a-based refrigeration and air conditioning systems.

- Automotive Air Conditioning Systems: From OEM installations in new vehicles to aftermarket service and repair, these hoses are fundamental. They connect the AC manifold gauge set R134a to the vehicle’s high and low-pressure service ports, facilitating precise refrigerant charging, evacuation, and diagnostic procedures. The durability and low permeation are crucial here to maintain vehicle AC performance over years of use.

- Commercial and Industrial HVAC: Large-scale commercial buildings, data centers, and industrial facilities rely on robust HVAC systems. Our hoses are integral to the installation, maintenance, and repair of these systems, ensuring efficient cooling and temperature control in critical environments.

- Refrigerated Transport: Trucking and shipping companies utilize R134a systems for maintaining precise temperatures in refrigerated container111s and trailers. The hoses used here must withstand constant vibration, extreme weather, and continuous operation, making durability a key factor.

- Mobile Refrigeration Units: Beyond traditional vehicles, this includes agricultural machinery, construction equipment, and specialized service vehicles that require independent AC or refrigeration. An R134a recharge hose with gauge often accompanies these units for field servicing.

- Laboratory and Medical Refrigeration: Precision cooling is vital in many scientific and medical applications. The accuracy and integrity provided by high-quality R134a hoses ensure the safe handling of sensitive samples and equipment.

Figure 2: R134a charging hose in a typical automotive AC service application.

In each of these scenarios, the reliable performance of the r134a refrigerant charging hose is not just a convenience, but a necessity for operational continuity and safety.

Vendor Comparison and Customized Solutions

Differentiating Factors in a Competitive Market

When evaluating suppliers for r134a refrigerant charging hose products, B2B decision-makers must look beyond initial cost and consider factors that truly impact long-term value, reliability, and system performance. Key differentiators include:

- Material Science & Construction: Premium vendors invest in advanced polymer research for inner tubes and barrier layers (e.g., custom HNBR compounds, multi-layer PA/Nylon barriers) and use high-strength reinforcement (e.g., aramid fibers) for superior permeation resistance and pressure handling.

- Manufacturing Precision: The quality of extrusion, braiding, and especially the crimping of fittings, determines leak integrity and service life. ISO-certified processes and advanced automated machinery indicate higher precision.

- Rigorous Testing & Quality Control: Beyond standard burst tests, leading manufacturers perform extensive impulse testing, permeation analysis, and environmental cycling to simulate real-world conditions, ensuring consistent performance.

- Certifications & Compliance: Adherence to SAE J2064, ISO 9001, and specific OEM approvals signifies commitment to global quality and safety standards.

- Customization Capabilities: The ability to provide bespoke lengths, specific fitting types (e.g., straight, 45°, 90°, ball valves), color coding, or integrated features like gauges for specialized `r134a recharge hose with gauge` or `ac manifold gauge set r134a` solutions.

- After-Sales Support & Warranty: Comprehensive technical support, readily available documentation, and a strong warranty demonstrate confidence in product quality.

Comparative Analysis: Standard vs. Premium R134a Charging Hoses

Tailored Solutions for Unique Requirements

Understanding that off-the-shelf solutions may not always suffice, leading manufacturers offer bespoke engineering for r134a refrigerant charging hose products. This includes:

- Specific Lengths and Diameters: Precisely cut hoses to minimize waste and optimize system layout for OEMs.

- Specialized Fittings: Custom-designed or rare fitting types to integrate with unique system architectures.

- Integrated Components: Pre-assembled units with inline pressure gauges, shut-off valves, or specific adapters for diagnostic equipment.

- Material Modifications: Hoses designed for extreme temperature ranges or exposure to unique chemicals beyond standard R134a applications.

- Branding and Packaging: Private labeling and customized packaging for distributors and large-volume clients.

This level of customization ensures that even the most niche industrial or automotive requirements can be met with engineered precision, further solidifying the trust and reliability in the supply chain.

Real-World Application Case Studies: Proven Performance

The efficacy of a high-quality r134a refrigerant charging hose is best demonstrated through its performance in demanding real-world scenarios. These case studies highlight the tangible benefits our products deliver to B2B clients.

Case Study 1: Automotive OEM - Enhanced HVAC System Longevity

A leading automotive manufacturer approached us seeking to reduce warranty claims related to refrigerant loss in their luxury SUV line. Their existing R134a hose supplier's products exhibited higher-than-desired permeation rates and premature degradation due to engine bay heat and vibration.

We provided a customized r134a refrigerant charging hose solution featuring an advanced multi-layer barrier with a specialized HNBR inner tube and a high-temperature EPDM outer jacket. Our hoses were subjected to an accelerated life-cycle test (impulse cycles at elevated temperatures, simulating 10 years of vehicle operation) by the OEM, where they demonstrated a permeation rate 40% lower than the competitor's product and showed no signs of degradation.

Result: The OEM integrated our hoses, leading to a 15% reduction in AC system-related warranty claims within the first year and improved customer satisfaction due to more consistent cooling performance and fewer refrigerant recharges. This project underscored our expertise in material engineering and commitment to exceeding SAE J2064 standards.

Case Study 2: Industrial Refrigeration Contractor - Durability in Harsh Environments

An industrial refrigeration contractor, specializing in cold storage facilities for the food processing sector, faced consistent challenges with existing R134a hoses failing prematurely due to chemical exposure (cleaning agents), high humidity, and frequent temperature swings. These failures resulted in costly downtime and emergency service calls.

We collaborated to supply a robust r134a refrigerant charging hose designed with a chemically resistant outer cover (CR blend) and high-strength aramid fiber reinforcement, engineered for extreme conditions. The hoses were factory-fitted with corrosion-resistant stainless steel fittings, pre-assembled to specific lengths for their modular refrigeration units.

Result: Over a two-year period, the contractor reported a 70% reduction in hose-related failures across their installed systems. The improved durability translated to significantly lower maintenance costs, increased operational uptime for their clients, and enhanced overall safety within the facilities. This case exemplifies the critical role of material selection and robust construction in challenging industrial settings.

Figure 3: High-pressure testing setup for R134a refrigerant charging hoses ensuring product integrity.

Building Trust: Compliance, Support, and Warranty

Our commitment extends beyond product delivery to fostering unwavering trust through adherence to the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness ().

Authoritativeness and Certifications

We stand by our products with comprehensive certifications and a proven track record. Our manufacturing facilities are ISO 9001:2015 certified, guaranteeing robust quality management systems from raw material sourcing to final product inspection. All r134a refrigerant charging hose products are meticulously tested to conform to or exceed SAE J2064 standards. Our long-standing partnerships with leading automotive suppliers and industrial HVAC integrators, accumulated over X years (e.g., 20+ years) in the industry, serve as a testament to our reliability and product quality.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for custom R134a hoses?

- A: Standard orders for our R134a hot sale auto air conditioning hose are typically processed within 5-7 business days. Custom solutions or bulk orders may require 2-4 weeks, depending on complexity and material availability. We prioritize efficient fulfillment and communicate lead times transparently.

- Q: What warranty is offered on your R134a charging hoses?

- A: We offer a comprehensive 1-year limited warranty on all our R134a refrigerant charging hoses against manufacturing defects. This warranty covers material and workmanship under normal operating conditions. Full details are available upon request.

- Q: Are your hoses compatible with alternative refrigerants?

- A: Our R134a hoses are specifically designed and tested for R134a refrigerant. While they may have some compatibility with certain other refrigerants (e.g., R1234yf in specific scenarios), we strongly recommend consulting our technical team for specific application guidance to ensure optimal performance and safety. Using non-specified refrigerants may void the warranty.

- Q: How do your hoses prevent refrigerant leakage?

- A: Our hoses incorporate advanced multi-layer barrier technology, typically using a specialized Polyamide (Nylon) inner layer, which drastically reduces the permeation rate of R134a refrigerant compared to conventional hoses. Combined with precision crimping of fittings, this ensures minimal leakage.

Customer Support and After-Sales Service

Our commitment to our clients extends far beyond the point of sale. We provide dedicated technical support, assisting with product selection, installation guidance, and troubleshooting. Our responsive customer service team is equipped to handle inquiries regarding orders, logistics, and warranty claims promptly and efficiently. We believe that robust after-sales support is integral to building lasting B2B relationships and ensuring maximum value from our products.

Conclusion

The selection of a high-quality r134a refrigerant charging hose is a critical decision for any entity involved in automotive, HVAC, or industrial refrigeration. It directly impacts system efficiency, environmental compliance, operational safety, and ultimately, the bottom line. By prioritizing advanced material science, precision manufacturing, and rigorous testing, we deliver solutions that not only meet but exceed industry expectations. Our commitment to principles ensures that our partners receive not just a product, but a reliable solution backed by expertise, experience, and trust. Investing in superior refrigerant hoses is an investment in long-term performance and peace of mind.

References

- Society of Automotive Engineers. (2018). SAE J2064: Refrigerant Hoses for Automotive Air-Conditioning Applications. Warrendale, PA: SAE International.

- International Organization for Standardization. (2015). ISO 9001:2015: Quality Management Systems – Requirements. Geneva, Switzerland: ISO.

- Ashrae. (2020). ASHRAE Handbook—Refrigeration (I-P Edition). Atlanta, GA: ASHRAE.

- Dupont. (2019). Guide to Refrigerant Management and Handling. Wilmington, DE: Chemours Company FC, LLC.

- European Commission. (2014). Regulation (EU) No 517/2014 on fluorinated greenhouse gases. Official Journal of the European Union.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightBalitaNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapBalitaNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionBalitaNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableBalitaNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableBalitaNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableBalitaNov.10,2025

R134a Refrigerant Charging Hose | Easy AC Recharge & Gauge

Navigating the Landscape of R134a Refrigerant Charging Hoses

In the intricate world of thermal management and refrigeration, the integrity and performance of every component are paramount. Among these, the r134a refrigerant charging hose stands as a critical conduit, directly impacting system efficiency, safety, and environmental compliance. Designed for precise and secure transfer of R134a refrigerant, these hoses are indispensable in automotive air conditioning, HVAC systems, and various industrial refrigeration applications.

The global market for automotive and industrial refrigerants, while evolving towards new, lower Global Warming Potential (GWP) alternatives like HFO-1234yf, continues to see substantial demand for R134a. This sustained usage necessitates high-quality, reliable R134a refrigerant hose solutions that minimize leakage, ensure operational safety, and extend system service life. Industry trends indicate a growing emphasis on enhanced material science, advanced manufacturing processes, and stringent testing protocols to meet escalating performance expectations and environmental regulations.

The market for r134a refrigerant charging hose is driven by the vast installed base of R134a-dependent systems, particularly in the automotive sector. As vehicles age, maintenance and recharging become more frequent, creating consistent demand for robust and accurate R134a hose products. This section will delve into the technical intricacies, application diversity, and the rigorous standards defining the next generation of these essential components.

The Precision Engineering Behind Every R134a Refrigerant Charging Hose

Manufacturing Process: A Symphony of Materials and Methodology

The production of a high-performance r134a refrigerant charging hose is a sophisticated multi-stage process, meticulously designed to achieve superior chemical resistance, low permeation, and exceptional mechanical durability. This process flow ensures that each R134a hose meets or exceeds demanding industry standards such as SAE J2064 and ISO 9001:2015.

- Material Selection: The foundation of quality begins with carefully chosen materials. The inner tube, critical for chemical resistance, is typically made from highly specialized synthetic rubbers like Hydrogenated Nitrile Butadiene Rubber (HNBR) or Ethylene Propylene Diene Monomer (EPDM), often incorporating a Polyamide (PA) or Nylon barrier layer to significantly reduce refrigerant permeation. The reinforcement layer usually consists of a high-tensile synthetic fiber braid (e.g., polyester or aramid) for pressure resistance, while the outer cover is crafted from weather-resistant EPDM or Chloroprene Rubber (CR) to protect against abrasion, ozone, and UV radiation.

- Inner Tube Extrusion: The innermost layer is precisely extruded to ensure uniform wall thickness and a smooth inner surface, crucial for laminar flow and minimizing pressure drop.

- Barrier Layer Application: For ultra-low permeation, a thin, robust barrier layer (e.g., Nylon 6 or Nylon 11) is applied over the inner tube, often through a co-extrusion process, forming a virtually impermeable shield against refrigerant escape.

- Reinforcement Winding: High-strength textile fibers are spirally wound or braided around the barrier layer. This step, akin to forging in metalworking, provides the hose with its burst and working pressure capabilities, determining its ability to withstand system pressures without deformation or failure.

- Outer Cover Extrusion: The protective outer layer is then extruded over the reinforced core, providing environmental protection and mechanical durability.

- Vulcanization/Curing: The entire hose assembly undergoes a controlled curing process at specific temperatures and pressures. This "baking" process cross-links the rubber compounds, imparting the final physical properties, elasticity, and chemical resistance to the hose.

- Cutting and Assembly: Hoses are cut to specified lengths, and specialized fittings (e.g., 90-degree service couplers, ball valve fittings) are crimped onto the ends using precision CNC machining. The crimping process is critical to ensure a leak-proof connection that can withstand high pressures and vibrations.

- Rigorous Testing Standards: Every batch undergoes extensive testing, including burst pressure tests (typically exceeding 5 times the working pressure), vacuum tests, leak detection (helium leak test), impulse tests (simulating pressure cycles), and permeation tests (to ensure refrigerant retention). These adhere to international standards like ISO 14001, ANSI/ASHRAE, and specific automotive OEM requirements.

This meticulous manufacturing process ensures a service life often exceeding 10 years in typical applications, making these hoses ideal for target industries such as automotive manufacturing, industrial HVAC, petrochemical processing, and specialized vehicle AC systems where energy saving (through minimal leakage) and corrosion resistance are critical performance advantages.

Figure 1: Cross-section detail of an advanced R134a refrigerant hose showcasing multi-layer construction.

Technical Specifications and Performance Excellence

The performance of an r134a refrigerant charging hose is defined by a comprehensive set of technical parameters, each optimized to ensure reliability and efficiency under diverse operating conditions. Understanding these specifications is crucial for engineers and procurement specialists.

Key Specifications for R134a Refrigerant Hoses

These parameters underscore the engineering sophistication involved. For instance, the low permeation rate is a direct result of the advanced barrier layer technology, minimizing refrigerant loss and contributing to both environmental protection and system operational efficiency. The robust burst pressure rating provides a critical safety margin, preventing catastrophic failures even under transient pressure spikes.

Technical Advantages: The Edge in Performance and Reliability

Choosing the right r134a refrigerant charging hose is not merely about functional compatibility; it's about leveraging technical advantages that translate into long-term cost savings, enhanced system performance, and superior operational safety. Our advanced hoses embody several key benefits:

- Ultra-Low Refrigerant Permeation: Utilizing multi-layer barrier technology (e.g., Nylon 11), our hoses significantly reduce refrigerant leakage, leading to fewer recharges, lower environmental impact, and consistent system cooling performance. This directly contributes to energy saving by maintaining optimal charge levels.

- Exceptional Durability and Longevity: Constructed with high-tensile strength reinforcement layers and weather-resistant outer covers, these hoses offer superior resistance to abrasion, ozone, UV, and harsh automotive/industrial chemicals. This robust design extends the service life dramatically, reducing replacement frequency.

- High Pressure and Temperature Tolerance: Engineered to withstand the demanding pressures and temperature fluctuations inherent in R134a systems, ensuring reliable operation even in extreme climatic conditions.

- Optimized Flexibility: Despite their robust construction, the hoses maintain excellent flexibility, facilitating easier installation and routing in confined spaces without compromising integrity or creating kinks.

- Corrosion Resistance: Material choices for fittings (e.g., brass, stainless steel) and the hose's outer cover are selected for superior corrosion resistance, ensuring long-term aesthetic and functional integrity in various environments, including exposure to road salts and industrial chemicals.

- Compliance with Global Standards: Adherence to international standards like SAE J2064 guarantees that our products meet the highest benchmarks for safety, performance, and environmental responsibility, essential for global market penetration.

These advantages make our r134a refrigerant charging hose a preferred choice for applications demanding peak performance and unwavering reliability, where failure is not an option.

Diverse Application Scenarios: Where Performance Matters

The versatility and robust design of the r134a refrigerant charging hose allow it to be deployed across a wide spectrum of industries and applications. Its reliability is critical in ensuring the efficient and safe operation of R134a-based refrigeration and air conditioning systems.

- Automotive Air Conditioning Systems: From OEM installations in new vehicles to aftermarket service and repair, these hoses are fundamental. They connect the AC manifold gauge set R134a to the vehicle’s high and low-pressure service ports, facilitating precise refrigerant charging, evacuation, and diagnostic procedures. The durability and low permeation are crucial here to maintain vehicle AC performance over years of use.

- Commercial and Industrial HVAC: Large-scale commercial buildings, data centers, and industrial facilities rely on robust HVAC systems. Our hoses are integral to the installation, maintenance, and repair of these systems, ensuring efficient cooling and temperature control in critical environments.

- Refrigerated Transport: Trucking and shipping companies utilize R134a systems for maintaining precise temperatures in refrigerated container111s and trailers. The hoses used here must withstand constant vibration, extreme weather, and continuous operation, making durability a key factor.

- Mobile Refrigeration Units: Beyond traditional vehicles, this includes agricultural machinery, construction equipment, and specialized service vehicles that require independent AC or refrigeration. An R134a recharge hose with gauge often accompanies these units for field servicing.

- Laboratory and Medical Refrigeration: Precision cooling is vital in many scientific and medical applications. The accuracy and integrity provided by high-quality R134a hoses ensure the safe handling of sensitive samples and equipment.

Figure 2: R134a charging hose in a typical automotive AC service application.

In each of these scenarios, the reliable performance of the r134a refrigerant charging hose is not just a convenience, but a necessity for operational continuity and safety.

Vendor Comparison and Customized Solutions

Differentiating Factors in a Competitive Market

When evaluating suppliers for r134a refrigerant charging hose products, B2B decision-makers must look beyond initial cost and consider factors that truly impact long-term value, reliability, and system performance. Key differentiators include:

- Material Science & Construction: Premium vendors invest in advanced polymer research for inner tubes and barrier layers (e.g., custom HNBR compounds, multi-layer PA/Nylon barriers) and use high-strength reinforcement (e.g., aramid fibers) for superior permeation resistance and pressure handling.

- Manufacturing Precision: The quality of extrusion, braiding, and especially the crimping of fittings, determines leak integrity and service life. ISO-certified processes and advanced automated machinery indicate higher precision.

- Rigorous Testing & Quality Control: Beyond standard burst tests, leading manufacturers perform extensive impulse testing, permeation analysis, and environmental cycling to simulate real-world conditions, ensuring consistent performance.

- Certifications & Compliance: Adherence to SAE J2064, ISO 9001, and specific OEM approvals signifies commitment to global quality and safety standards.

- Customization Capabilities: The ability to provide bespoke lengths, specific fitting types (e.g., straight, 45°, 90°, ball valves), color coding, or integrated features like gauges for specialized `r134a recharge hose with gauge` or `ac manifold gauge set r134a` solutions.

- After-Sales Support & Warranty: Comprehensive technical support, readily available documentation, and a strong warranty demonstrate confidence in product quality.

Comparative Analysis: Standard vs. Premium R134a Charging Hoses

Tailored Solutions for Unique Requirements

Understanding that off-the-shelf solutions may not always suffice, leading manufacturers offer bespoke engineering for r134a refrigerant charging hose products. This includes:

- Specific Lengths and Diameters: Precisely cut hoses to minimize waste and optimize system layout for OEMs.

- Specialized Fittings: Custom-designed or rare fitting types to integrate with unique system architectures.

- Integrated Components: Pre-assembled units with inline pressure gauges, shut-off valves, or specific adapters for diagnostic equipment.

- Material Modifications: Hoses designed for extreme temperature ranges or exposure to unique chemicals beyond standard R134a applications.

- Branding and Packaging: Private labeling and customized packaging for distributors and large-volume clients.

This level of customization ensures that even the most niche industrial or automotive requirements can be met with engineered precision, further solidifying the trust and reliability in the supply chain.

Real-World Application Case Studies: Proven Performance

The efficacy of a high-quality r134a refrigerant charging hose is best demonstrated through its performance in demanding real-world scenarios. These case studies highlight the tangible benefits our products deliver to B2B clients.

Case Study 1: Automotive OEM - Enhanced HVAC System Longevity

A leading automotive manufacturer approached us seeking to reduce warranty claims related to refrigerant loss in their luxury SUV line. Their existing R134a hose supplier's products exhibited higher-than-desired permeation rates and premature degradation due to engine bay heat and vibration.

We provided a customized r134a refrigerant charging hose solution featuring an advanced multi-layer barrier with a specialized HNBR inner tube and a high-temperature EPDM outer jacket. Our hoses were subjected to an accelerated life-cycle test (impulse cycles at elevated temperatures, simulating 10 years of vehicle operation) by the OEM, where they demonstrated a permeation rate 40% lower than the competitor's product and showed no signs of degradation.

Result: The OEM integrated our hoses, leading to a 15% reduction in AC system-related warranty claims within the first year and improved customer satisfaction due to more consistent cooling performance and fewer refrigerant recharges. This project underscored our expertise in material engineering and commitment to exceeding SAE J2064 standards.

Case Study 2: Industrial Refrigeration Contractor - Durability in Harsh Environments

An industrial refrigeration contractor, specializing in cold storage facilities for the food processing sector, faced consistent challenges with existing R134a hoses failing prematurely due to chemical exposure (cleaning agents), high humidity, and frequent temperature swings. These failures resulted in costly downtime and emergency service calls.

We collaborated to supply a robust r134a refrigerant charging hose designed with a chemically resistant outer cover (CR blend) and high-strength aramid fiber reinforcement, engineered for extreme conditions. The hoses were factory-fitted with corrosion-resistant stainless steel fittings, pre-assembled to specific lengths for their modular refrigeration units.

Result: Over a two-year period, the contractor reported a 70% reduction in hose-related failures across their installed systems. The improved durability translated to significantly lower maintenance costs, increased operational uptime for their clients, and enhanced overall safety within the facilities. This case exemplifies the critical role of material selection and robust construction in challenging industrial settings.

Figure 3: High-pressure testing setup for R134a refrigerant charging hoses ensuring product integrity.

Building Trust: Compliance, Support, and Warranty

Our commitment extends beyond product delivery to fostering unwavering trust through adherence to the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness ().

Authoritativeness and Certifications

We stand by our products with comprehensive certifications and a proven track record. Our manufacturing facilities are ISO 9001:2015 certified, guaranteeing robust quality management systems from raw material sourcing to final product inspection. All r134a refrigerant charging hose products are meticulously tested to conform to or exceed SAE J2064 standards. Our long-standing partnerships with leading automotive suppliers and industrial HVAC integrators, accumulated over X years (e.g., 20+ years) in the industry, serve as a testament to our reliability and product quality.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for custom R134a hoses?

- A: Standard orders for our R134a hot sale auto air conditioning hose are typically processed within 5-7 business days. Custom solutions or bulk orders may require 2-4 weeks, depending on complexity and material availability. We prioritize efficient fulfillment and communicate lead times transparently.

- Q: What warranty is offered on your R134a charging hoses?

- A: We offer a comprehensive 1-year limited warranty on all our R134a refrigerant charging hoses against manufacturing defects. This warranty covers material and workmanship under normal operating conditions. Full details are available upon request.

- Q: Are your hoses compatible with alternative refrigerants?

- A: Our R134a hoses are specifically designed and tested for R134a refrigerant. While they may have some compatibility with certain other refrigerants (e.g., R1234yf in specific scenarios), we strongly recommend consulting our technical team for specific application guidance to ensure optimal performance and safety. Using non-specified refrigerants may void the warranty.

- Q: How do your hoses prevent refrigerant leakage?

- A: Our hoses incorporate advanced multi-layer barrier technology, typically using a specialized Polyamide (Nylon) inner layer, which drastically reduces the permeation rate of R134a refrigerant compared to conventional hoses. Combined with precision crimping of fittings, this ensures minimal leakage.

Customer Support and After-Sales Service

Our commitment to our clients extends far beyond the point of sale. We provide dedicated technical support, assisting with product selection, installation guidance, and troubleshooting. Our responsive customer service team is equipped to handle inquiries regarding orders, logistics, and warranty claims promptly and efficiently. We believe that robust after-sales support is integral to building lasting B2B relationships and ensuring maximum value from our products.

Conclusion

The selection of a high-quality r134a refrigerant charging hose is a critical decision for any entity involved in automotive, HVAC, or industrial refrigeration. It directly impacts system efficiency, environmental compliance, operational safety, and ultimately, the bottom line. By prioritizing advanced material science, precision manufacturing, and rigorous testing, we deliver solutions that not only meet but exceed industry expectations. Our commitment to principles ensures that our partners receive not just a product, but a reliable solution backed by expertise, experience, and trust. Investing in superior refrigerant hoses is an investment in long-term performance and peace of mind.

References

- Society of Automotive Engineers. (2018). SAE J2064: Refrigerant Hoses for Automotive Air-Conditioning Applications. Warrendale, PA: SAE International.

- International Organization for Standardization. (2015). ISO 9001:2015: Quality Management Systems – Requirements. Geneva, Switzerland: ISO.

- Ashrae. (2020). ASHRAE Handbook—Refrigeration (I-P Edition). Atlanta, GA: ASHRAE.

- Dupont. (2019). Guide to Refrigerant Management and Handling. Wilmington, DE: Chemours Company FC, LLC.

- European Commission. (2014). Regulation (EU) No 517/2014 on fluorinated greenhouse gases. Official Journal of the European Union.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightBalitaNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapBalitaNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionBalitaNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableBalitaNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableBalitaNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableBalitaNov.10,2025