Durable Flexible Hose Connectors for Versatile Plumbing Solutions and Applications

The Importance of Flexible Hose Connectors in Modern Applications

Flexible hose connectors play a crucial role in a variety of industries, serving as vital components in fluid and gas transfer systems. These connectors, designed to absorb movement, vibration, and thermal expansion, are instrumental in ensuring the reliability and efficiency of many applications, from automotive systems to industrial machinery and plumbing.

One of the primary functions of flexible hose connectors is to accommodate the movement of connected parts. In many systems, components may shift due to mechanical operations or thermal expansion. The flexibility of these hoses allows for this movement while maintaining a leak-proof seal, thereby preventing potential failures or hazardous spills. For example, in automotive applications, flexible hoses connect different parts of the engine system, ensuring that fuels, oil, and coolant flow smoothly, even as the engine vibrates during operation.

In addition to their mechanical benefits, flexible hose connectors are also essential for safety in fluid transfer systems. Many fluids transported through these hoses can be hazardous, including chemicals, fuels, and pressurized gases. The robust construction and flexible nature of these hoses reduce the likelihood of ruptures or leaks, protecting both the environment and personnel. The use of high-quality materials such as reinforced rubber or stainless steel can further enhance safety and durability, making flexible hose connectors a preferred choice in industries like chemical processing and oil and gas.

flexible hose connector

Moreover, flexible hose connectors are versatile and adaptable, available in a wide range of sizes, lengths, and materials. This versatility enables engineers to design systems that are tailored to specific operational needs. Whether it’s a small plumbing application in a residential setting or a large-scale industrial operation, flexible hoses can be customized to fit unique requirements. Their ability to navigate complex layouts and tight spaces makes them indispensable in modern engineering.

Additionally, the installation and maintenance of flexible hose connectors can be straightforward, contributing to enhanced system efficiency. Many flexible hose systems can be installed without specialized tools, making them user-friendly for technicians and maintenance personnel. Regular inspections and easy replacements further contribute to their appeal, as any wear or damage can be addressed quickly to minimize downtime and maintain operational integrity.

Environmental considerations also play a significant role in the design and selection of flexible hose connectors. Many manufacturers are now focusing on creating eco-friendly options that minimize ecological impact. By employing sustainable practices and materials, companies can meet stringent regulations while still providing high-performance products.

In conclusion, flexible hose connectors are fundamental components in many fluid and gas applications, providing essential functions that enhance safety, efficiency, and adaptability. Their ability to accommodate movement while preventing leaks makes them vital in a wide range of industries, including automotive, plumbing, and chemical processing. As technology continues to evolve, the importance of these versatile connectors will only amplify, driving further innovations in their design and application. For engineers and businesses alike, investing in high-quality flexible hose connectors is paramount to ensure reliability and performance in their operations.

-

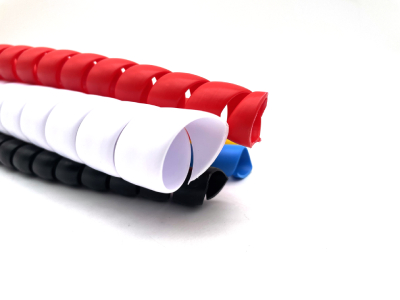

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025