Explore Various Types of Pneumatic Air Hose Connectors for Efficient Fluid Transfer Solutions

Understanding Pneumatic Air Hose Connectors A Comprehensive Guide

Pneumatic air hose connectors are essential components in the realm of compressed air systems, serving as the junction points where hoses connect to tools, machines, and other hoses. These connectors play a pivotal role in ensuring efficient air transfer, making them crucial for various industries, including manufacturing, construction, automotive, and even home workshops. In this article, we will delve into the types, functions, and considerations involved in selecting the right pneumatic air hose connectors.

Types of Pneumatic Air Hose Connectors

Pneumatic air hose connectors come in several types, each designed for specific applications and requirements

1. Quick-Connect Couplings These connectors allow for quick and easy connection and disconnection of hoses without the need for tools. They are ideal for applications requiring frequent changes of tools or equipment, promoting efficiency and reducing downtime.

2. Barbed Fittings Commonly used in low-pressure applications, barbed fittings have ridges that grip the hose, providing a secure connection. They are often made from durable materials such as brass or plastic and are suitable for various air and fluid transfer tasks.

3. Compression Fittings These connectors use a compression mechanism to create a tight seal between the hose and the fitting. They are commonly utilized in high-pressure applications due to their strong, reliable connections.

4. Threaded Fittings With male and female threads, these connectors are screw-fitted to provide a robust bond. They are ideal for permanent installations where the hose is not frequently disconnected.

5. Swivel Fittings These connectors allow for rotation to prevent hose kinking and improve maneuverability. They are especially useful in applications where hoses are frequently moved or adjusted.

Functions of Pneumatic Air Hose Connectors

The primary function of pneumatic air hose connectors is to facilitate the seamless transfer of compressed air. However, they also serve several other critical roles

- Pressure Maintenance A good connector ensures that the air pressure remains consistent throughout the system, which is vital for the optimal performance of pneumatic tools.

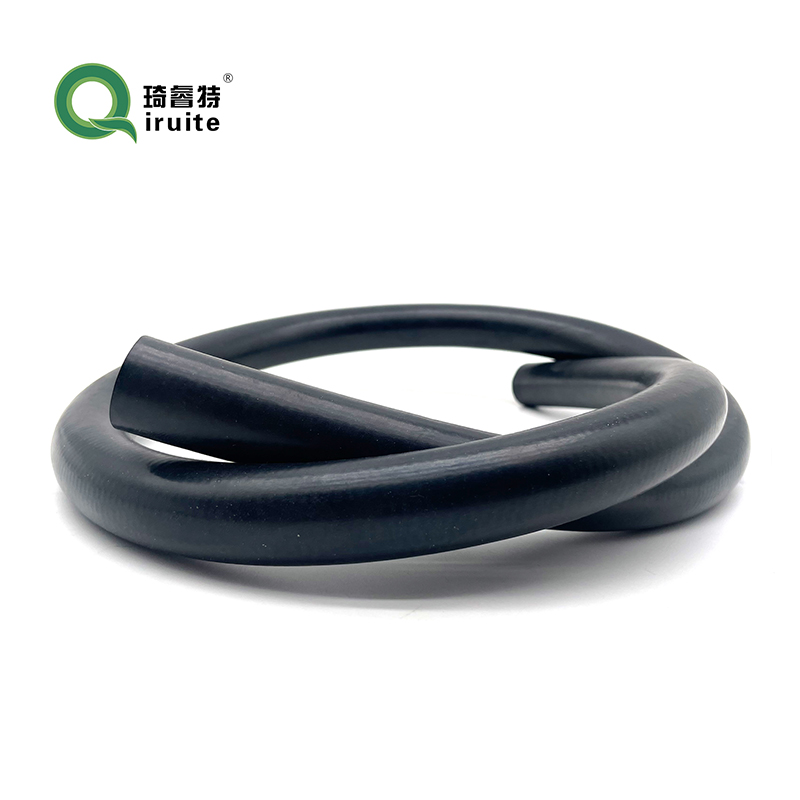

pneumatic air hose connector

- Leak Prevention Quality connectors are designed to minimize leaks, which not only enhances efficiency but also reduces safety hazards associated with compressed air systems

.- Versatility With various types of connectors available, users can customize their setups according to specific needs, whether it’s for high-pressure applications or more flexible arrangements.

Selecting the Right Connector

When choosing pneumatic air hose connectors, several factors should be considered

1. Pressure Rating Always select connectors that match or exceed the pressure ratings required for your application to ensure safety and performance.

2. Temperature Resistance Different materials have varying temperature tolerances. Consider the operating temperature of your compressed air system when selecting connectors.

3. Material Compatibility Ensure that the material of the connector is compatible with the hoses and fluids it will be used with. Common materials include brass, stainless steel, and various plastics.

4. Ease of Use Depending on your application, you may need connectors that allow for quick disconnects without the use of tools. This can save time and improve productivity.

5. Size and Threading Ensure that the diameter and threading of the connector fit the hoses and tools you plan to use. Mismatched sizes can lead to inefficiencies and potential leaks.

Conclusion

Pneumatic air hose connectors are more than just accessories; they are integral components that enhance the efficiency and safety of compressed air systems. By understanding the different types of connectors, their functions, and how to select the right one for your application, you can ensure a reliable and seamless operation in your pneumatic systems. Whether for industrial use or casual DIY projects, investing in the right air hose connectors is a step towards achieving optimal performance and efficiency in any compressed air setup.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025