Barbed Flex Pipe Coupling Durable & Leak-Proof Connector for AC Flex Pipe Easy Installation

Unlock Leak-Proof Performance: The Ultimate Guide to Barbed Flex Pipe Couplings

Ever been blindsided by a leaking ac flex pipe in mid-summer? Maybe your power steering hose started hissing during rush hour traffic, leaving you stranded. According to the American Society of Plumbing Engineers, water loss from faulty pipe connections accounts for over 900 million gallons of wasted water every day in the U.S. That’s more than enough to fill 1,300 Olympic-size pools—daily. What's the cost to you? Time, stress, money, and maybe even safety. But what if there’s a smarter, simpler, and stronger solution? Enter the barbed flex pipe coupling

.

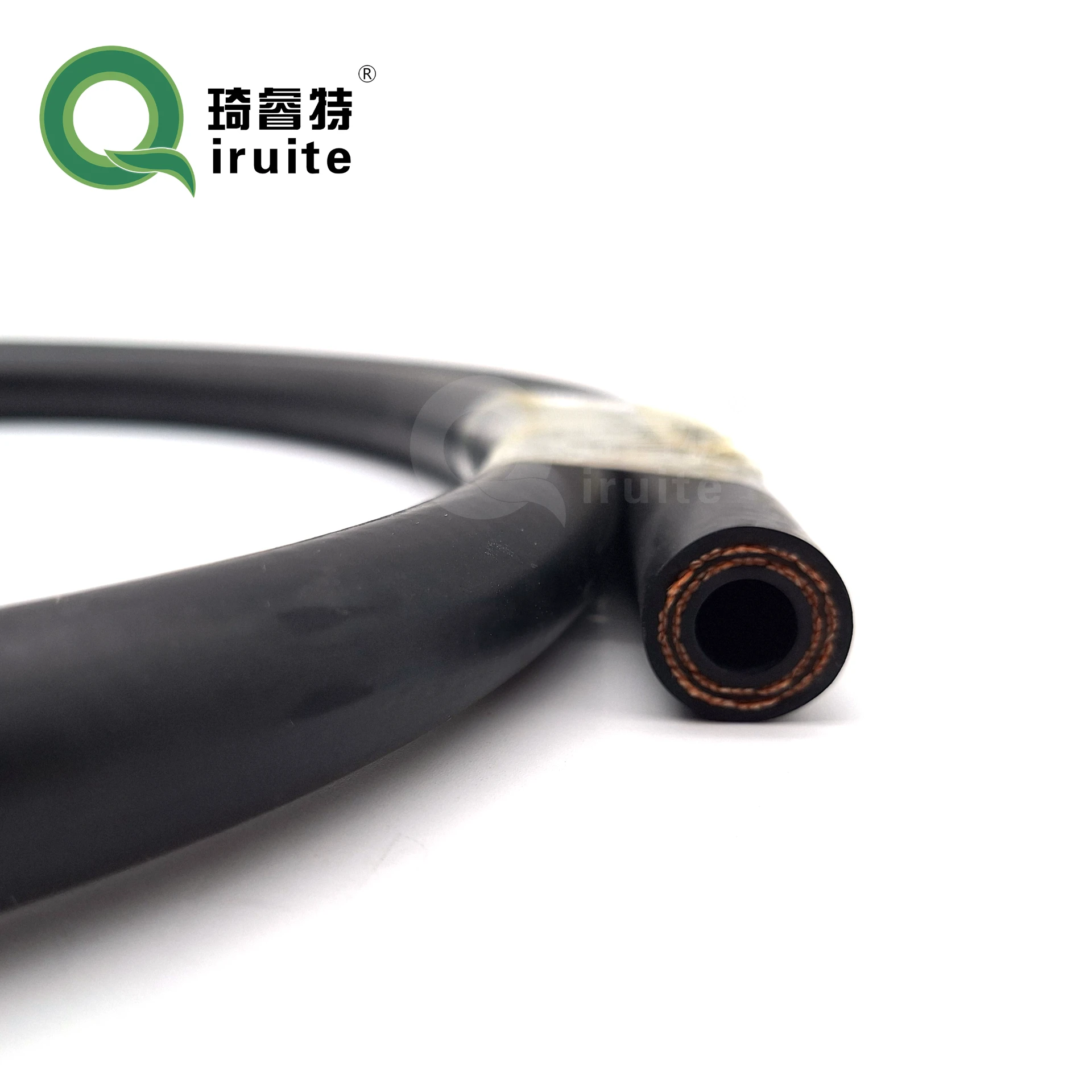

(barbed flex pipe coupling)

Why Barbed Flex Pipe Couplings Outperform Traditional Connectors

Traditional pipe couplings often demand precision tools and trained hands. Miss one small step and you risk leaks—potentially catastrophic, always inconvenient. The barbed flex pipe coupling flips the script. Why? Its design is simple, strong, and forgiving. You don’t need a degree in hydraulics. Just slide, tighten, and go.

- High tensile grip prevents blowouts.

- Ribbed barbs lock tight, even under thermal expansion.

- Compatible with a range of materials: PVC, PEX, EPDM, copper.

- No welding, no specialized crimping tools required.

- Permanent or temporary—your call.

Ready for extreme weather? You bet. These fittings maintain full integrity from sub-zero freezes to blazing summers. Try flex tape on power steering hose for a “quick fix?” That’s temporary at best. But a barbed flex pipe coupling keeps every drop locked in—guaranteed.

| Specification | Barbed Flex Coupling | Traditional Metal Clamp |

|---|---|---|

| Max Pressure | 350 psi | 200 psi |

| Corrosion Resistance | Excellent (304 SS/Brass) | Good |

| Reusability | Yes | Limited |

| Install Time | Under 2 minutes | 5-10 minutes |

Choosing the Right Manufacturer: Why It Pays To Compare

You've got options—but not all manufacturers deliver superior quality. Your choice affects every job’s outcome. Top-tier barbed flex pipe coupling makers don’t just crank out fittings. They invest in:

- Premium materials (304/316 stainless, high-grade brass alloys)

- Precision barbing for maximum grip

- Tight tolerances—flawless fits every time

- Comprehensive pressure and leak testing

- ANSI/ASTM certified quality standards

Inferior products may look the part, but one bad fitting can flood an attic, wreck a vehicle, or destroy trust. So, how do you pick a winner? Look for decades of expertise, real performance data, and flexible order options. It's your call, but a manufacturer with ISO 9001 certification and a robust warranty stands behind every claim.

| Feature | High-End Manufacturer | Generic Factory |

|---|---|---|

| Material Certification | Guaranteed, traceable | Unknown |

| Pressure Test Records | Available on request | Seldom |

| Minimum Order Size | Low/Flexible | High/Restrictive |

| Custom Fittings | Yes | Rare |

Custom-Tailored Barbed Flex Pipe Coupling Solutions

Pipes aren’t just pipes—every installation is different. Maybe you’re retrofitting a vintage Mustang’s ac flex pipe. Or engineering a new HVAC grid for a hospital. That’s where customization matters.

- Custom lengths and barb profiles for any hose diameter

- Material selection—304 stainless steel to non-conductive plastics

- Color-coded or laser-etched for easy field identification

- Fit-for-purpose design: high-flow, compact, or extra vibration-resistant

Don’t settle for “almost right.” Streamlined custom coupling production cuts your maintenance costs, boosts system efficiency, and shows clients you think ahead.

Real-World Applications: Barbed Flex Pipe Coupling Case Studies

Skeptical? Those “quick fixes”—like flex tape on power steering hose—might hold for days. But professionals know that one reliable connection is worth a hundred patches.

Case 1: A Midwest dairy lost $18,000/day due to faulty tube connectors in their milking machines. Upgraded with FDA-approved barbed flex pipe couplings, not a single hose line has failed in three years.

Case 2: A Texas HVAC installer reduced callbacks by 92% after switching to customized, color-coded fittings, slashing labor time and preventing missed connections under pressure.

Case 3: A Brooklyn auto shop replaced old clamped power steering lines with heavy-duty barbed couplings. Zero returns. Zero customer complaints. Maximum peace of mind.

The numbers don’t lie—the right coupling pays for itself in reliability and performance. Wouldn’t you want the same confidence in your next project?

Product Specification Table: Barbed Flex Pipe Coupling

| Parameter | |

|---|---|

| Material | 304 Stainless Steel / Brass / Nylon |

| Working Pressure | Up to 350 psi |

| Temperature Range | -58°F to 320°F |

| Compatibility | PVC, PEX, EPDM, Silicone, Rubber |

| Sizes | 1/4" to 2" |

| Certifications | ANSI/ASTM Compliant |

Ready for Instant Upgrades?

Why risk a botched job and costly callbacks? Replace anxiety with assurance. You deserve components as tough as your team. Our American-designed barbed flex pipe couplings set the new industry standard. Fast install. Leak-proof. Ultra-durable.

Contact us today to tap into custom solutions, wholesale pricing, and expedited shipping. As a top-tier manufacturer with 25+ years of innovation, we’re ready to push your projects further, faster, leak-free. Want to transform downtime into zero time lost? Choose experience. Choose quality. Choose us. Your next system—stronger, smarter, and built to last.

Professional FAQs on Barbed Flex Pipe Coupling

Q1. What is a barbed flex pipe coupling and how does it work?

A barbed flex pipe coupling is a connector with sharp, rib-like barbs. These grip securely inside flexible piping, creating a tight, leak-resistant seal. Simply slide the coupling into the pipe and clamp or cinch it for a lasting hold—no specialist tools required.

Q2. Can I use barbed flex pipe couplings with ac flex pipe or power steering hose?

Absolutely! Barbed flex pipe couplings are widely compatible with both ac flex pipe and power steering hoses. They’re engineered to withstand high pressure and temperature cycles often seen in automotive and HVAC systems.

Q3. Is flex tape on power steering hose a good alternative?

Flex tape on power steering hose might offer a fast, temporary fix but can't match the long-term security of a barbed flex pipe coupling. For lasting reliability, always use proper couplings for vehicle systems under pressure.

Q4. What sizes and materials are available for barbed flex pipe couplings?

Standard sizes range from 1/4" to 2". Materials include 304/316 stainless steel, brass, nylon, and even high-strength polymers for harsh chemicals or food-grade use.

Q5. Are your barbed flex pipe couplings certified for industrial standards?

Yes. Our couplings comply with ANSI/ASTM standards, undergo strict quality controls, and are backed by comprehensive documentation—every order.

Q6. How do I install a barbed flex pipe coupling?

Cut the pipe clean, slide on the coupling, and secure it with an approved clamp or cinch ring. No torches or epoxy required. You get a powerful seal in under two minutes.

Q7. How do barbed flex pipe couplings compare to traditional fittings?

Barbed flex pipe couplings offer superior grip, faster installation, and broader compatibility. They drastically reduce leak risks compared to old-school clamped or welded joints—especially in vibration-prone settings.

(barbed flex pipe coupling)

FAQS on barbed flex pipe coupling

Q: What is a barbed flex pipe coupling used for?

A: A barbed flex pipe coupling is used to securely join flexible pipes or hoses, especially in plumbing and automotive systems. Its barbed ends provide a tight, leak-resistant grip. This coupling is ideal for connecting hoses carrying air, water, or fluids.Q: Can a barbed flex pipe coupling be used with ac flex pipe?

A: Yes, a barbed flex pipe coupling can connect ac flex pipe sections. Ensure the coupling size matches your ac flex pipe's diameter. This provides a reliable and flexible seal for HVAC systems.Q: Is it safe to use flex tape on a power steering hose?

A: Flex tape is not recommended for power steering hoses, as it may not withstand high pressure or hydraulic fluid. Temporary emergency use is possible, but proper hose replacement is advised. Always use fittings or hose replacements designed for power steering systems.Q: How do I install a barbed flex pipe coupling?

A: To install, simply push the flexible hose onto the barbed ends of the coupling. Using hose clamps ensures a tight, leak-proof seal. Make sure to match the coupling size with your hose for best results.Q: What materials are barbed flex pipe couplings typically made from?

A: Barbed flex pipe couplings are commonly made of brass, stainless steel, or durable plastic. Material choice depends on your fluid type and pressure needs. Always choose a coupling compatible with your application environment.-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025