john deere 425 power steering hose

The Importance of Power Steering Hoses A Focus on John Deere 425

When it comes to the maintenance and operation of agricultural equipment, understanding the role of various components is essential for both efficiency and safety. One such component that often goes overlooked is the power steering hose, especially in equipment like the John Deere 425 lawn and garden tractor. This article will delve into the function, construction, maintenance, and replacement of the power steering hose, emphasizing its importance to the overall performance of the machinery.

Understanding Power Steering in the John Deere 425

Power steering is a critical feature in modern tractors, including the John Deere 425. It allows the operator to control the vehicle with minimal effort, ensuring precise maneuverability without straining the operator. This is especially important in agricultural settings where the terrain can be challenging, and time is of the essence. The power steering system relies on hydraulic pressure, which is generated by the power steering pump and transmitted through the power steering hose.

Function of the Power Steering Hose

The power steering hose is a vital conduit that transfers hydraulic fluid from the power steering pump to the steering gear and back. This fluid pressurizes the system, enabling the tractor to turn smoothly and easily. A malfunctioning hose can lead to a range of issues, from difficulties in steering to complete hydraulic failure, rendering the tractor nearly impossible to operate.

Construction and Durability

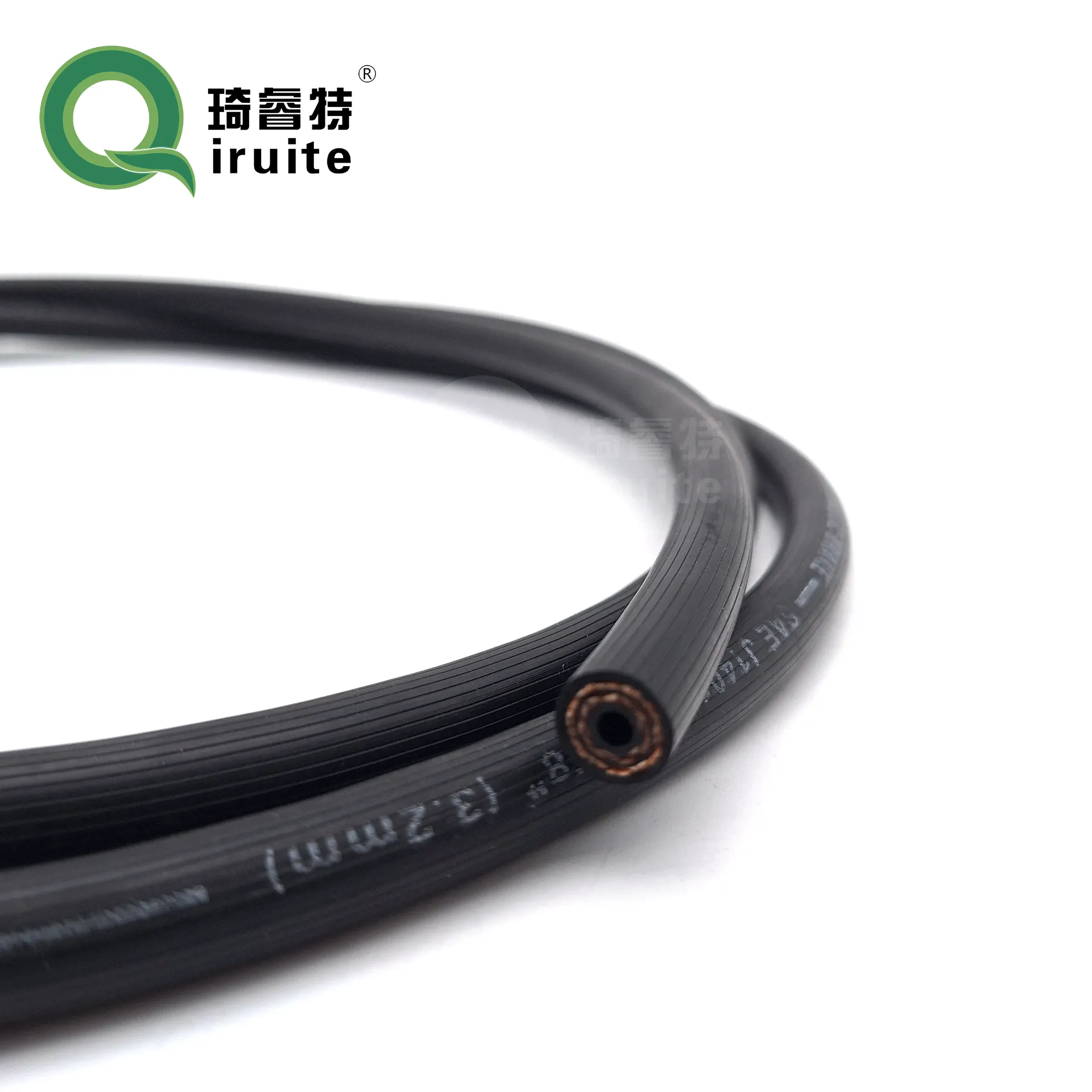

Typically, power steering hoses are made from high-strength rubber or a combination of rubber and synthetic materials designed to withstand the high pressures generated within the hydraulic system. They are also often reinforced with braided wire or other materials to enhance durability and prevent bursting. Despite this, hoses are subject to wear and tear due to factors like temperature fluctuations, exposure to chemicals, and physical damage. Regular inspections are essential to identify any signs of degradation early.

Signs of a Failing Power Steering Hose

Operators of the John Deere 425 should be vigilant for symptoms that may indicate a failing power steering hose. Common signs include

- Fluid Leaks The most obvious sign is the presence of hydraulic fluid pooling under the tractor

. Any leaks should be addressed immediately as they can lead to a significant decrease in steering performance.- Difficult Steering If the tractor becomes increasingly hard to steer, it may be a symptom of low hydraulic fluid levels caused by a compromised hose.

john deere 425 power steering hose

- Unusual Noises Any whining or groaning noises when turning the steering wheel may indicate that the hydraulic fluid is not circulating properly, often due to a malfunctioning hose.

Maintenance and Inspection

To ensure the longevity of the power steering hose, regular maintenance is crucial. Operators should include the following in their maintenance routine

1. Visual Inspections Regularly check the hose for cracks, abrasions, or other signs of wear.

2. Fluid Levels Monitor the hydraulic fluid levels in the reservoir, and top up as necessary with the recommended type of fluid.

3. Testing Steering Performance Periodically assess the steering performance. Any drop in efficiency should warrant further investigation.

4. Professional Servicing Whenever in doubt, seek assistance from a professional mechanic or a John Deere service center. They can perform more in-depth diagnostics and maintenance.

Replacement of the Power Steering Hose

If a power steering hose is found to be damaged or leaking, it is crucial to replace it promptly. For the John Deere 425, replacement hoses are readily available, either through official John Deere retailers or third-party suppliers. When replacing the hose, ensure that the new component meets the specifications required for the John Deere 425 to maintain optimal performance.

Conclusion

In conclusion, while the power steering hose may seem like a small component in the grand scheme of a tractor's operation, its importance cannot be overstated. For John Deere 425 operators, maintaining and replacing this critical part when necessary will ensure smoother operation, greater efficiency, and a safer work environment. By keeping an eye on signs of trouble and adhering to a routine maintenance schedule, operators can prolong the life of their equipment and enhance their overall productivity.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025