يانۋار . 28, 2025 03:30

Back to list

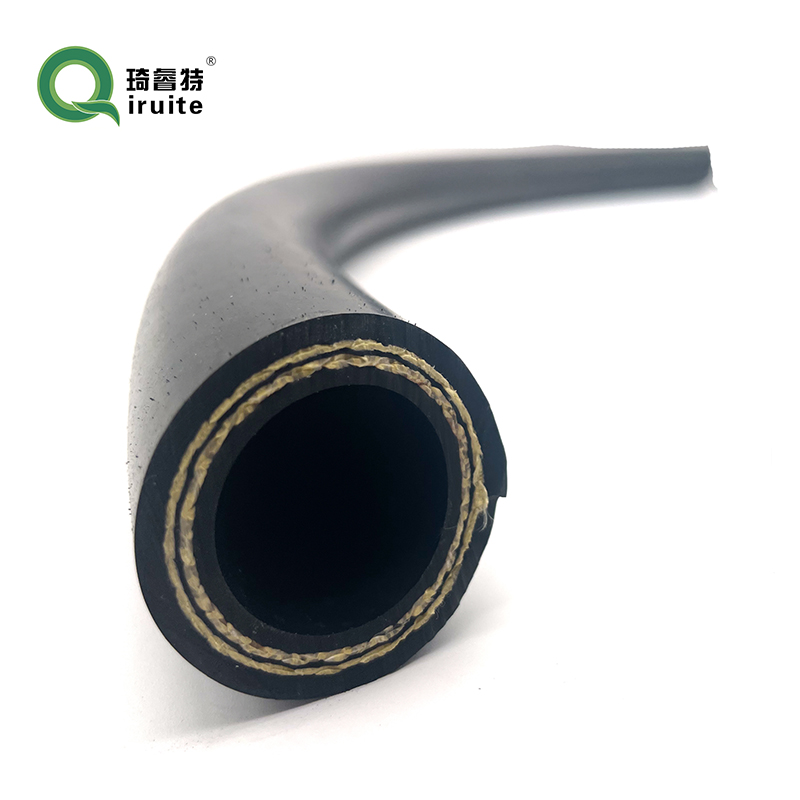

brake hose sae j1401

When it comes to ensuring the safety and effectiveness of a vehicle's braking system, brake hose connectors play a crucial yet often overlooked role. These small but vital components bridge the brake hose and brake caliper or wheel cylinder, allowing the fluid to transmit seamlessly and ensuring the vehicle stops when the brake pedal is pressed. The importance of choosing the right brake hose connector cannot be understated, as it directly impacts the overall functionality and safety of the braking system.

In addition to theoretical expertise, real-world testing is a strength found in trustworthy brands and suppliers. Many leading manufacturers subject their brake hose connectors to rigorous testing protocols before releasing them to the market. This might include simulated stress tests, exposure to high temperatures, and trials under varying pressure conditions to ensure the product can handle extreme scenarios, providing users with peace of mind. Moreover, the importance of trustworthiness in brake hose connectors ties back to consumer reviews and testimonials. Mechanics and automotive experts often share their experiences with different brands and types of connectors, offering valuable insights into their real-world performance. Reviews discussing installation ease, longevity, and performance under different driving conditions provide an authentic glimpse into what potential buyers can expect. Consumers exploring these descriptors can discern which products are reliable and worth investing in, based on feedback from those who have already made the purchase. All these aspects—experience, expertise, authoritativeness, and trustworthiness—converge to guide informed decisions about brake hose connectors. Vehicle owners and automotive professionals should prioritize these elements to select connectors that not only fit but perform optimally. A well-chosen brake hose connector represents a commitment to safety and quality, ensuring that each drive is as secure as it is smooth. Ultimately, investing time in understanding these components leads to enhanced braking performance, contributing to overall vehicle safety.

In addition to theoretical expertise, real-world testing is a strength found in trustworthy brands and suppliers. Many leading manufacturers subject their brake hose connectors to rigorous testing protocols before releasing them to the market. This might include simulated stress tests, exposure to high temperatures, and trials under varying pressure conditions to ensure the product can handle extreme scenarios, providing users with peace of mind. Moreover, the importance of trustworthiness in brake hose connectors ties back to consumer reviews and testimonials. Mechanics and automotive experts often share their experiences with different brands and types of connectors, offering valuable insights into their real-world performance. Reviews discussing installation ease, longevity, and performance under different driving conditions provide an authentic glimpse into what potential buyers can expect. Consumers exploring these descriptors can discern which products are reliable and worth investing in, based on feedback from those who have already made the purchase. All these aspects—experience, expertise, authoritativeness, and trustworthiness—converge to guide informed decisions about brake hose connectors. Vehicle owners and automotive professionals should prioritize these elements to select connectors that not only fit but perform optimally. A well-chosen brake hose connector represents a commitment to safety and quality, ensuring that each drive is as secure as it is smooth. Ultimately, investing time in understanding these components leads to enhanced braking performance, contributing to overall vehicle safety.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025