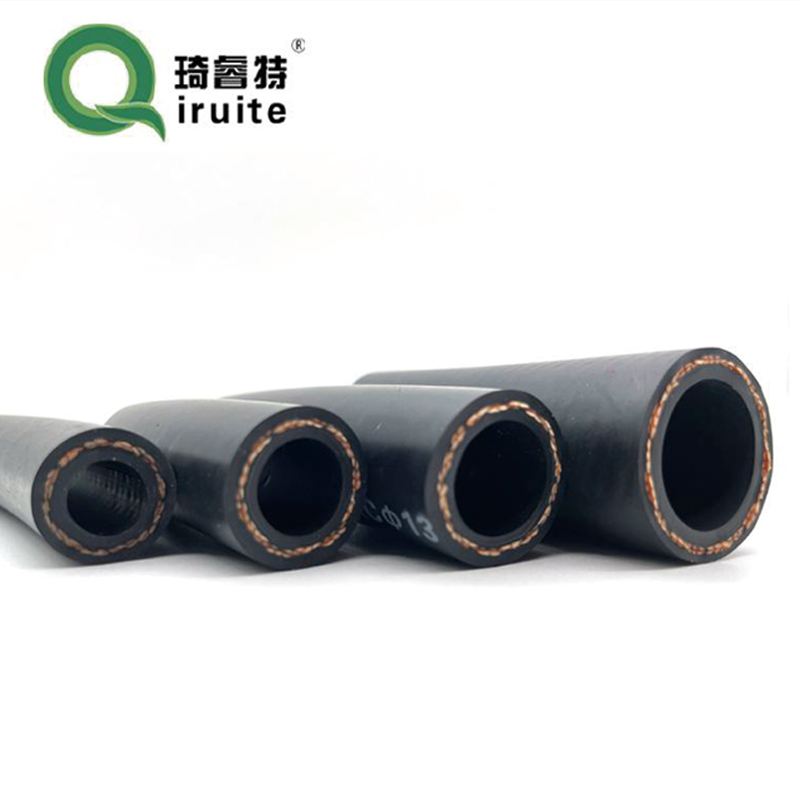

1 1 2 hose coupling

Understanding 1% 201% 202% Hose Coupling Applications and Importance

Hose couplings play a vital role in numerous industries, serving as the connecting devices between hoses and other equipment. Among the various types of hose couplings, the 1% 201% 202% hose coupling stands out due to its unique properties and specifications. Understanding this type of coupling is essential for anyone working with fluid transfer systems, as the right coupling can impact efficiency, safety, and durability.

What is Hose Coupling?

A hose coupling is a device that joins hoses to pipes, pumps, or nozzles. These couplings can be permanent or removable, depending on the application. They are used in various industries, including agriculture, construction, firefighting, and manufacturing. A reliable hose coupling ensures secure connections, preventing leaks, spills, and hazards associated with high-pressure systems.

The Significance of 1% 201% 202% Hose Coupling

The specific designation of 1% 201% 202% refers to the material composition and performance characteristics of the coupling, suggesting qualities important for specific applications. The 1% indicates a feature that might involve a 1% tolerance on part dimensions, offering precision during manufacturing. In contrast, 201% and 202% could denote different parameters related to pressure ratings, corrosion resistance, and temperature tolerances.

These couplings are manufactured to withstand challenging conditions, including high-pressure environments, extreme temperatures, and exposure to various chemicals. Such attributes make the 1% 201% 202% hose coupling particularly suitable for industries that deal with hazardous fluids or require robust systems.

Applications in Various Industries

1 1 2 hose coupling

1. Agriculture Farmers frequently use hose couplings to connect irrigation systems. Given the varying pressures and types of water being transported, the reliable sealing and durability of the 1% 201% 202% hoses ensure efficient and safe water delivery to crops.

2. Firefighting In firefighting, the reliability of hose couplings is paramount. The 1% 201% 202% hose coupling is designed to handle high-pressure water demands and can withstand the rigors of emergency situations.

3. Manufacturing In manufacturing, where machinery often operates under high pressure, these couplings are utilized to connect different lengths of hose and facilitate fluid transfer. Their durability reduces maintenance costs and downtime.

4. Chemical Processing The resistance to corrosive substances makes the 1% 201% 202% hose coupling an excellent choice for chemical processing industries. These couplings keep hazardous fluids contained and ensure the safety of workers.

Choosing the Right Hose Coupling

When selecting a hose coupling, consider the specific requirements of your application. Factors such as fluid type, temperature ranges, pressure levels, and potential environmental exposures all influence the choice of coupling. The 1% 201% 202% hose coupling offers a reliable solution for intricate systems, providing peace of mind to operators who depend on fluid transfer.

Conclusion

In conclusion, the 1% 201% 202% hose coupling is more than just a component; it is a critical element that supports various industrial processes. By ensuring secure and reliable connections, it prevents leaks and breakdowns, contributing to overall efficiency and safety. As industries evolve and demands grow, the importance of selecting the right hose coupling will continue to rise, making knowledge of options like the 1% 201% 202% crucial for professionals in the field.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025