barbed flex pipe coupling

Understanding Barbed Flex Pipe Couplings An Essential Component in Fluid Systems

Barbed flex pipe couplings are crucial components in fluid delivery systems, especially in water, air, and various liquid applications. These couplings are designed to connect flexible hoses or pipes securely, ensuring a leak-proof seal while allowing for flexibility and movement in the piping system. Their unique design offers several advantages that make them popular in various industries, including irrigation, aquaculture, and general plumbing.

The barbed design of these couplings is essential for preventing disconnection and leaks. The barbs create a friction fit that holds the pipe in place when pushed onto the coupling. As the hose slides over the barbs, it creates a tight seal, which helps to maintain the pressure within the system. This is particularly important in applications where fluid loss can lead to significant problems, such as in irrigation systems where water conservation is vital.

One of the primary benefits of barbed flex pipe couplings is their versatility. They can accommodate a range of hose sizes and types, making them suitable for various applications. Whether dealing with PVC, rubber, or silicone hoses, barbed couplings can ensure a secure connection. This flexibility is a significant advantage for contractors and engineers who need to use different materials and sizes in their systems.

barbed flex pipe coupling

Installation of barbed flex pipe couplings is relatively straightforward, which is another reason for their popularity. Users typically only require a hose clamp to secure the connection further. After sliding the hose onto the coupling, a hose clamp can be tightened around the hose to prevent any movement or slippage, ensuring a long-lasting connection. This ease of installation minimizes labor costs and time, making them an efficient choice for contractors.

Durability is another hallmark of barbed flex pipe couplings. They are commonly made from materials like polypropylene, PVC, and stainless steel, ensuring they can withstand various environmental conditions. This robustness is vital in outdoor applications, where exposure to ultraviolet (UV) rays, temperature fluctuations, and moisture can degrade inferior materials.

Moreover, barbed flex pipe couplings are designed to handle various pressures, making them suitable for both low and high-pressure applications. This adaptability further extends their use across multiple industries, from agricultural irrigation systems to industrial fluid transport.

In conclusion, barbed flex pipe couplings are indispensable components in fluid systems, offering reliability, durability, and versatility. Their ability to create secure connections without the need for complex tools or fittings makes them a favorite among professionals in multiple fields. As industries continue to seek efficient and effective solutions for fluid transport, the demand for reliable components like barbed flex pipe couplings will undoubtedly remain strong. Emphasizing quality and appropriate application when selecting these couplings will ensure optimal performance and longevity in any piping system.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

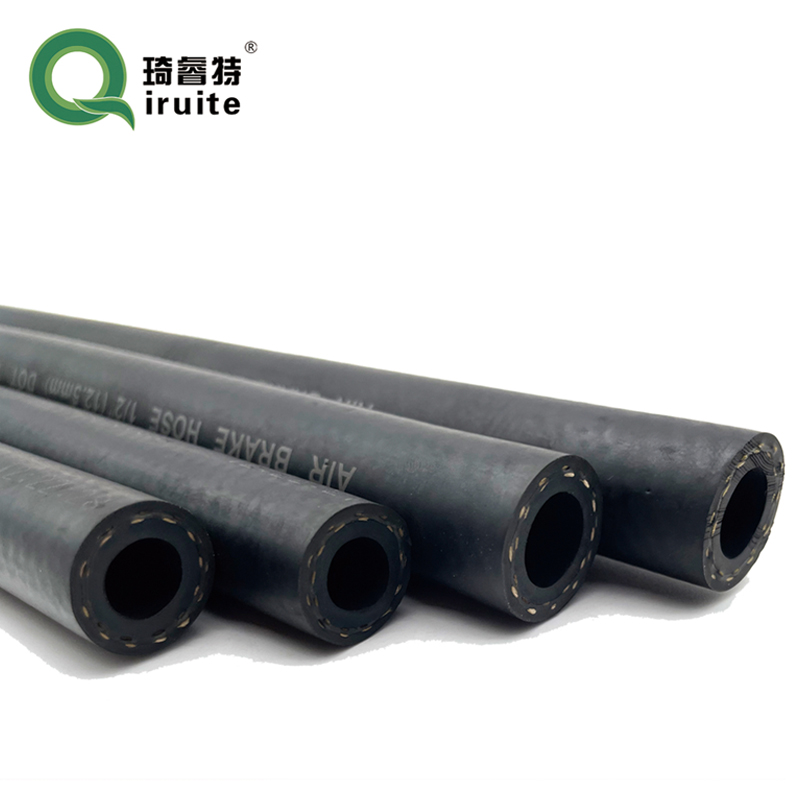

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025