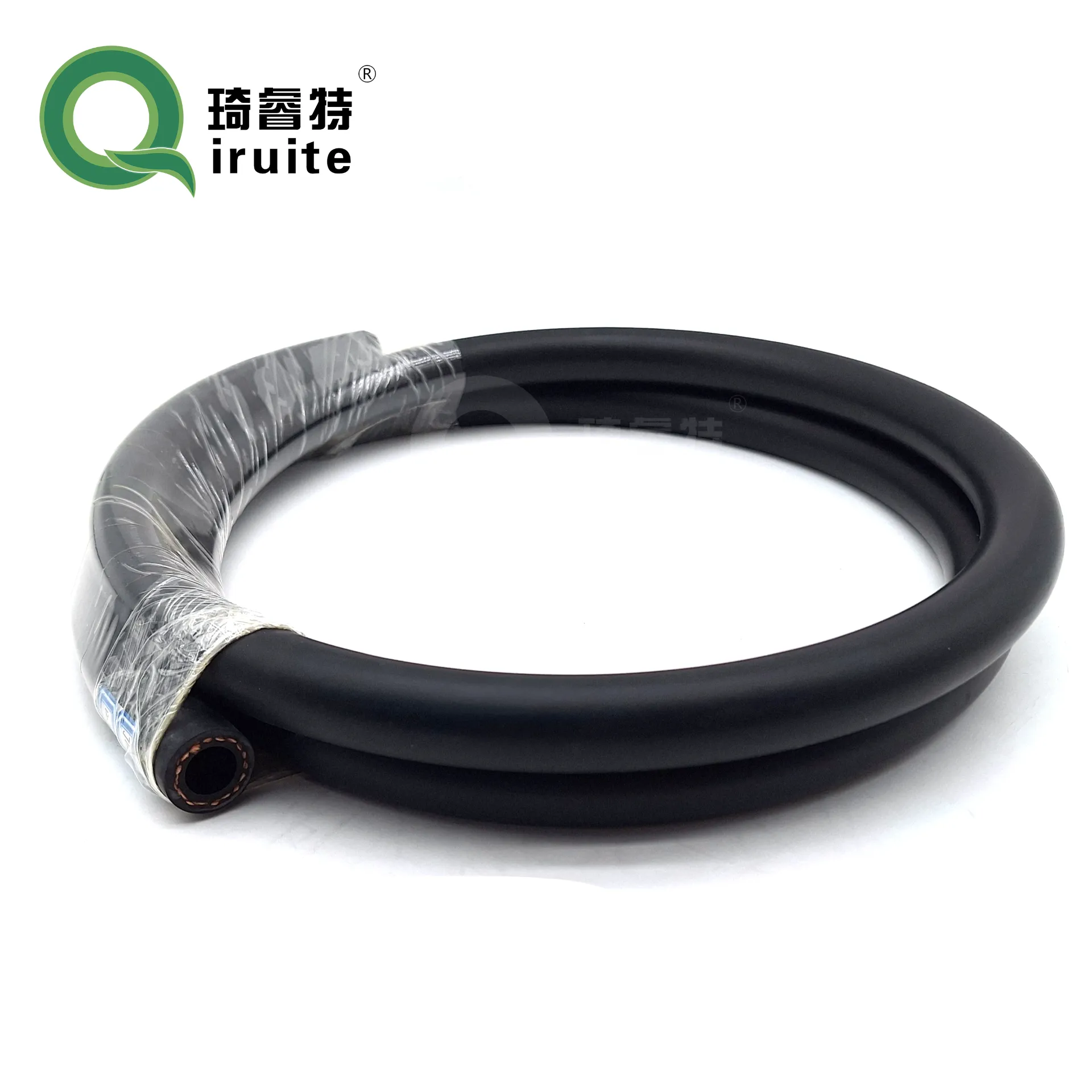

pipe coupling

Understanding Pipe Couplings Essential Components for Fluid Management

Pipe couplings are vital components in various industries, playing a crucial role in the management and transportation of fluids and gases. These fittings are essential for connecting two pipes in a piping system, allowing for expansion, contraction, and maintenance of the pipeline. With the increasing demand for efficient fluid transport solutions across sectors such as plumbing, construction, oil and gas, and chemical processing, understanding the types and applications of pipe couplings has never been more critical.

Types of Pipe Couplings

Pipe couplings come in a wide variety of types, each designed to serve specific functions and meet particular requirements. The most common types include

1. Rigid Couplings These couplings are designed to permanently connect two pipe ends, ensuring there is no movement between the pipes. They are often used in systems where the pipes are not subject to thermal expansion or contraction.

2. Flexible Couplings Unlike rigid couplings, flexible couplings allow for some degree of movement between pipes. This flexibility is crucial in scenarios involving vibration, misalignment, or thermal expansion. Flexible couplings typically feature rubber or similar materials that absorb shock and provide a seal.

3. Slip Couplings These couplings are used to repair damaged pipes without needing to remove them entirely. Slip couplings can slide over the ends of the pipes, allowing for quick repairs and reducing downtime.

4. Reduction Couplings When connecting pipes of different diameters, reduction couplings come into play. They facilitate a seamless transition from a larger pipe to a smaller one, maintaining flow efficiency.

5. Union Couplings These couplings are designed for easy disassembly, allowing for quick maintenance or replacement of pipe sections. Unions are particularly useful in applications where frequent adjustments or repairs are expected.

Applications of Pipe Couplings

pipe coupling

The versatility of pipe couplings allows them to be used across multiple industries

- Plumbing Pipe couplings are extensively used in residential and commercial plumbing systems to connect various sections of piping, ensuring the efficient transport of water and waste.

- Oil and Gas In the oil and gas industry, couplings are critical for connecting pipes transporting oil, natural gas, and other fluids under high pressure.

- Chemical Processing The chemical industry requires robust and reliable piping systems to handle various chemicals. Couplings in these systems must be resistant to corrosion and capable of withstanding extreme temperatures.

- Construction Pipe couplings play a significant role in construction projects, particularly for draining and irrigation systems, ensuring that the infrastructure is adequately connected and functions seamlessly.

Choosing the Right Pipe Coupling

When selecting a pipe coupling, several factors should be considered, including the type of material being transported, the pressure and temperature conditions, and the specific application. Common materials for pipe couplings include PVC, stainless steel, brass, and cast iron, each offering distinct advantages depending on the environment.

Furthermore, it is essential to ensure that the coupling is compatible with the pipe it will connect. Mismatched couplings can lead to leaks, joint failures, and potentially hazardous situations.

Conclusion

In summary, pipe couplings are indispensable elements in fluid management systems across various industries. Understanding their types, applications, and selection criteria is essential for ensuring the efficiency and safety of piping systems. With technological advancements and a growing emphasis on sustainability, the design and materials used for pipe couplings are continually evolving, paving the way for more efficient fluid transport solutions. Whether in a residential plumbing project or a large-scale industrial operation, the significance of choosing the right pipe coupling cannot be overstated. By investing in quality couplings and understanding their function and application, industries can enhance their operational efficiency and minimize the risks associated with fluid transport.

-

Understanding Power Steering Tube ReplacementNewsApr.16,2025

-

SAE J1401 Brake Hoses: A Critical Component for Vehicle SafetyNewsApr.16,2025

-

Pipe Couplings: Essential Components for Effective Plumbing and Fluid SystemsNewsApr.16,2025

-

Hose Guard Solutions for Every NeedNewsApr.16,2025

-

Effective Spiral Protection SolutionsNewsApr.16,2025

-

Effective Sewer Cleaning SolutionsNewsApr.16,2025