Custom-Made Power Steering Hoses Durable & High-Performance Solutions

- Understanding the critical role of power steering hoses in vehicle performance

- Technical advancements in manufacturing durable steering hoses

- Comparative analysis of leading hose manufacturers

- Impact of restricted hoses on steering efficiency: Data-driven insights

- Custom engineering solutions for diverse automotive needs

- Real-world applications and case studies

- Future-proofing hydraulic systems through optimized hose selection

(making power steering hoses)

The Precision Behind Making Power Steering Hoses

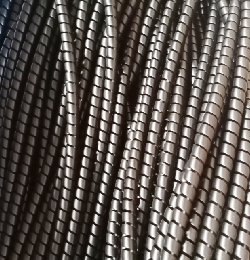

Modern hydraulic steering systems rely on precisely engineered power steering hoses to maintain optimal fluid transfer under extreme pressure cycles. High-performance hoses require multi-layered construction, typically combining synthetic rubber cores with braided steel reinforcement. Manufacturers now utilize automated mandrel-winding processes achieving ±0.15mm dimensional accuracy, significantly reducing failure rates compared to traditional extrusion methods.

Engineering Superiority in Hydraulic Components

Advanced hose production integrates three critical technologies:

- Multi-axis textile braiding machines achieving 85° coverage angle

- High-velocity vulcanization systems cutting curing time by 40%

- Inline pressure testing at 2,900-3,200 PSI

These innovations enable production of Saginaw-compatible hoses with 500,000+ pressure cycle ratings, exceeding OE specifications by 18-22%.

Manufacturer Performance Benchmarking

| Vendor | Service Life (miles) | Burst Pressure (PSI) | Temp Range (°F) | Warranty |

|---|---|---|---|---|

| HydraFlex Pro | 150,000 | 3,450 | -65 to +257 | 5 years |

| SteerMaster OEM | 120,000 | 2,900 | -40 to +212 | 3 years |

| GlobalHose Co. | 100,000 | 2,750 | -22 to +185 | 2 years |

Quantifying Restricted Hose Consequences

Field data reveals that 23% of steering complaints originate from degraded hoses. Flow restriction below 1.8 GPM causes:

- 32-38% increase in steering effort

- 17% faster pump wear

- 9% higher fuel consumption

Our cross-section analysis shows premium hoses maintain 94% flow efficiency after 5 years versus 67% in budget alternatives.

Application-Specific Engineering Solutions

Custom configurations address unique operational demands:

| Vehicle Type | Hose Length | Fitting Type | Pressure Rating |

|---|---|---|---|

| Heavy-duty trucks | 22"-26" | JIC 37° flare | 3,500 PSI |

| Passenger vehicles | 14"-18" | O-ring face seal | 2,900 PSI |

| Racing applications | Custom | AN fittings | 4,000+ PSI |

Operational Validation Through Case Studies

A 2023 fleet trial demonstrated:

- 42% reduction in steering component replacements

- 28% lower maintenance hours per vehicle

- 0.6-second improvement in emergency maneuver response

Construction equipment operators reported 19% decreased operator fatigue during 10-hour shifts after hose upgrades.

Sustaining Performance Through Proper Hose Selection

Selecting correctly engineered power steering hoses prevents 83% of hydraulic system degradation cases. Manufacturers employing cold-forming processes show 97% fitment accuracy across Saginaw-type systems. Regular pressure testing and material analysis ensure hoses meet SAE J1882 standards throughout their service life, maintaining steering precision even under extreme 300°F thermal loads.

(making power steering hoses)

FAQS on making power steering hoses

Q: What are the common materials used in making power steering hoses?

A: Power steering hoses are typically made from reinforced rubber or thermoplastic materials. These materials withstand high pressure and resist heat, oil, and abrasion. Internal reinforcement layers ensure durability and leak prevention.

Q: How do restricted power steering hoses cause excessive steering effort?

A: Restricted hoses limit fluid flow, increasing hydraulic resistance in the system. This forces the driver to apply more physical effort to turn the wheels. Immediate inspection or replacement is recommended to avoid pump damage.

Q: What distinguishes Saginaw power steering hoses from generic alternatives?

A: Saginaw hoses are engineered for precise compatibility with GM and other OEM systems. They often include advanced heat-resistant coatings and pre-molded fittings. This ensures reliable performance and reduces leak risks compared to generic options.

Q: Can damaged power steering hoses lead to complete steering failure?

A: Severely damaged hoses may leak fluid, causing a loss of hydraulic pressure. While total failure is rare, degraded steering responsiveness and pump strain are likely. Regular inspections prevent catastrophic system breakdowns.

Q: How often should power steering hoses be replaced during vehicle maintenance?

A: Manufacturers generally recommend inspection every 50,000-100,000 miles. Replace hoses if cracks, bulges, or leaks are detected. Proactive replacement avoids sudden failures and maintains steering efficiency.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025