Exploring High-Quality Pipe Couplings for Efficient Plumbing Solutions and Improved Water Flow Dynamics

Understanding 6 Pipe Couplings A Comprehensive Overview

Pipe couplings are critical components in various plumbing and industrial applications, designed for connecting and securing sections of pipe. Among the various types of pipe couplings available in the market, the 6 pipe coupling exemplifies a specific design and application that offers a combination of durability, efficiency, and ease of installation.

Definition and Functionality

A 6 pipe coupling is often characterized by its standard diameter and is typically made of materials such as stainless steel, brass, or PVC, depending on the application requirements. The term 6 is often used in industry jargon to denote specific sizing standards or types of couplings, though it might also represent a particular application in plumbing systems.

The primary function of a pipe coupling is to connect two lengths of pipe. This connection can be necessary for extending a pipeline, repairing a damage, or modifying existing plumbing systems. A 6 pipe coupling is designed to ensure a tight and leak-proof fit, which is crucial for maintaining system integrity and safety.

Types of 6 Pipe Couplings

There are several types of pipe couplings available, each suitable for different applications

1. Coupling Fittings These are the most common types, allowing for secure connections between two pipes of similar diameters. They can be either threaded or slip-on, catering to different installation preferences.

2. Reduction Couplings Used when connecting pipes of different diameters, these couplings feature one end that is larger or smaller than the other, making them versatile for various plumbing scenarios.

3. Flexible Couplings These are essential in applications where vibration or movement is expected, providing flexibility while maintaining a strong connection.

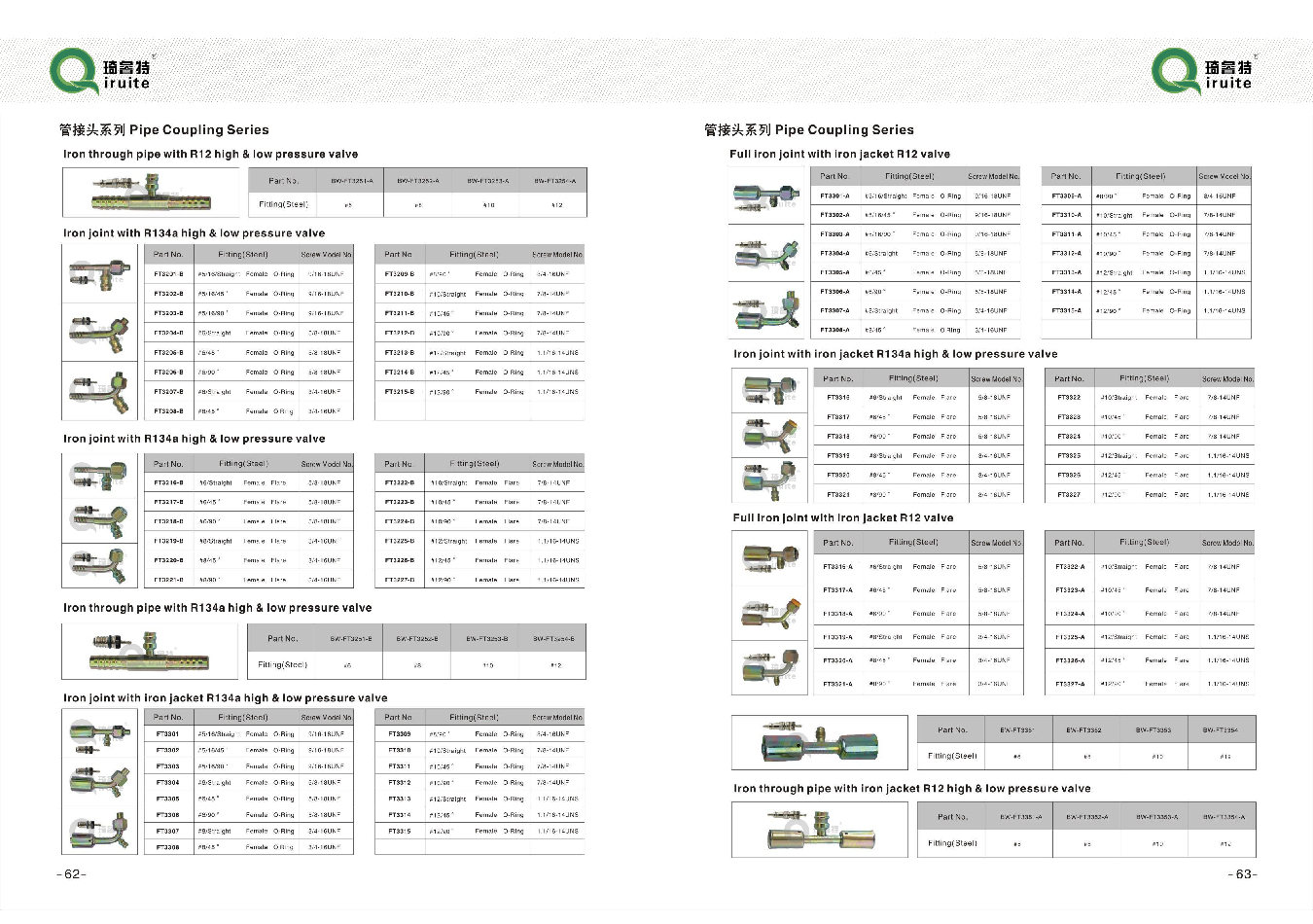

6 pipe coupling

4. PVC Couplings Ideal for residential plumbing, PVC couplings are lightweight yet strong and resistant to corrosion.

Each type comes with its own advantages and is suitable for specific situations, whether for water transportation, drainage systems, or gas lines.

Importance of Choosing the Right Coupling

Selecting the correct 6 pipe coupling is critical for ensuring the functionality and longevity of any piping system. The wrong choice can lead to leaks, pressure loss, and increased maintenance costs. Factors to consider include the type of pipe material, the intended application, temperature and pressure conditions, and local plumbing codes.

Installation Considerations

Installing a 6 pipe coupling requires not only the right tools but also the necessary skills to guarantee a proper fit. Common tools include pipe wrenches, saws, and measuring tapes. It is vital to clean and prepare the pipe ends before fitting to prevent contamination and ensure the coupling seals properly. For threaded couplings, applying thread sealant is crucial to avoid leaks.

Maintenance and Inspection

Regular inspection and maintenance of pipe couplings can significantly extend their lifespan. Look for signs of wear, such as corrosion or leaks, and address them promptly. In commercial and industrial settings, scheduled maintenance routines can help avoid downtime and costly repairs.

Conclusion

In summary, understanding the 6 pipe coupling and its applications within plumbing and industrial systems is essential for anyone involved in installation and maintenance. By selecting the right type of coupling, ensuring proper installation, and conducting regular inspections, users can facilitate efficient fluid transportation while minimizing potential hazards. Whether in residential or commercial environments, the functional integrity of a piping system largely depends on the appropriate use of couplings.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025