Understanding Power Steering Hose Routing for Optimal Performance and Safety in Automotive Systems

Power Steering Hose Routing A Comprehensive Guide

Power steering systems are fundamental components in modern vehicles, providing drivers with the ease of maneuverability by amplifying the steering effort. One of the critical aspects of a power steering system is the routing of the hoses that carry hydraulic fluid from the pump to the steering gearbox or rack. Proper hose routing is essential not just for the functionality of the steering system but also for the safety and longevity of the vehicle.

Importance of Proper Hose Routing

The routing of power steering hoses affects several factors, including pressure regulation, fluid flow efficiency, and component wear. Incorrect routing can lead to numerous issues. For instance, if the hoses are too close to hot engine components, the heat can degrade the rubber material of the hoses, potentially leading to leaks. On the other hand, if the hoses are not secured properly, they may rub against sharp edges or moving parts, resulting in wear that can cause catastrophic failures.

Key Considerations for Hose Routing

1. Clearance

When routing power steering hoses, maintaining adequate clearance from other components is crucial. Hoses should be positioned away from exhaust systems, engine blocks, and other heat-generating parts. Additionally, it's important to ensure there is enough space to prevent the hoses from being pinched during vehicle operation or while the engine is running.

2. Bends and Turns

Maintaining smooth bends in the hoses is vital. Sharp turns can create stress points, leading to premature wear or kinks that hinder fluid flow. The preferred radius for bends should be as gentle as possible, allowing for fluid to flow smoothly through the system. When routing the hoses, aim for a path that minimizes sharp angles and maximizes fluid efficiency.

power steering hose routing

Using appropriate clamps and brackets to secure the hoses is essential. Loose hoses can chafe against other components, leading to wear and potential leakage. Clamps should be positioned at regular intervals to ensure consistent support and to prevent the hoses from moving around during operation.

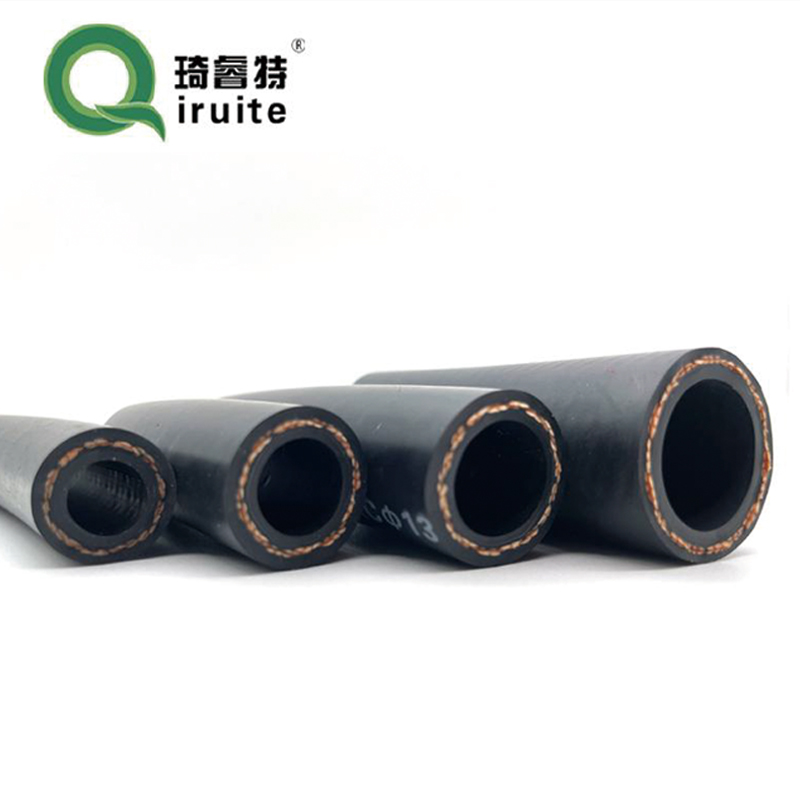

4. Material Selection

Choosing the right hose material also plays a critical role in the longevity of the power steering system. Hoses should be manufactured from high-quality materials that can withstand the pressures of the hydraulic system and resist deterioration from heat and oil exposure.

5. Regular Inspections

Routine inspections of the power steering system, particularly the hoses, are necessary to identify any signs of wear, cracking, or bulging. Addressing any issues promptly can prevent more significant problems down the line, ensuring the system operates effectively.

Conclusion

The routing of power steering hoses may seem like a minor detail in the overall function of a vehicle, but it is far from trivial. Proper hose routing can significantly impact vehicle safety, performance, and maintenance costs. By following best practices—ensuring proper clearance, avoiding sharp bends, securing hoses adequately, selecting appropriate materials, and performing regular inspections—drivers can enjoy a reliable and efficient power steering system. Understanding the importance of correct hose routing is essential not only for mechanics and automotive engineers but also for vehicle owners who wish to maintain their cars in optimal condition. Remember, in automotive engineering, attention to detail can make all the difference, and that definitely applies to power steering hose routing.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025