Februari . 10, 2025 10:33

Back to list

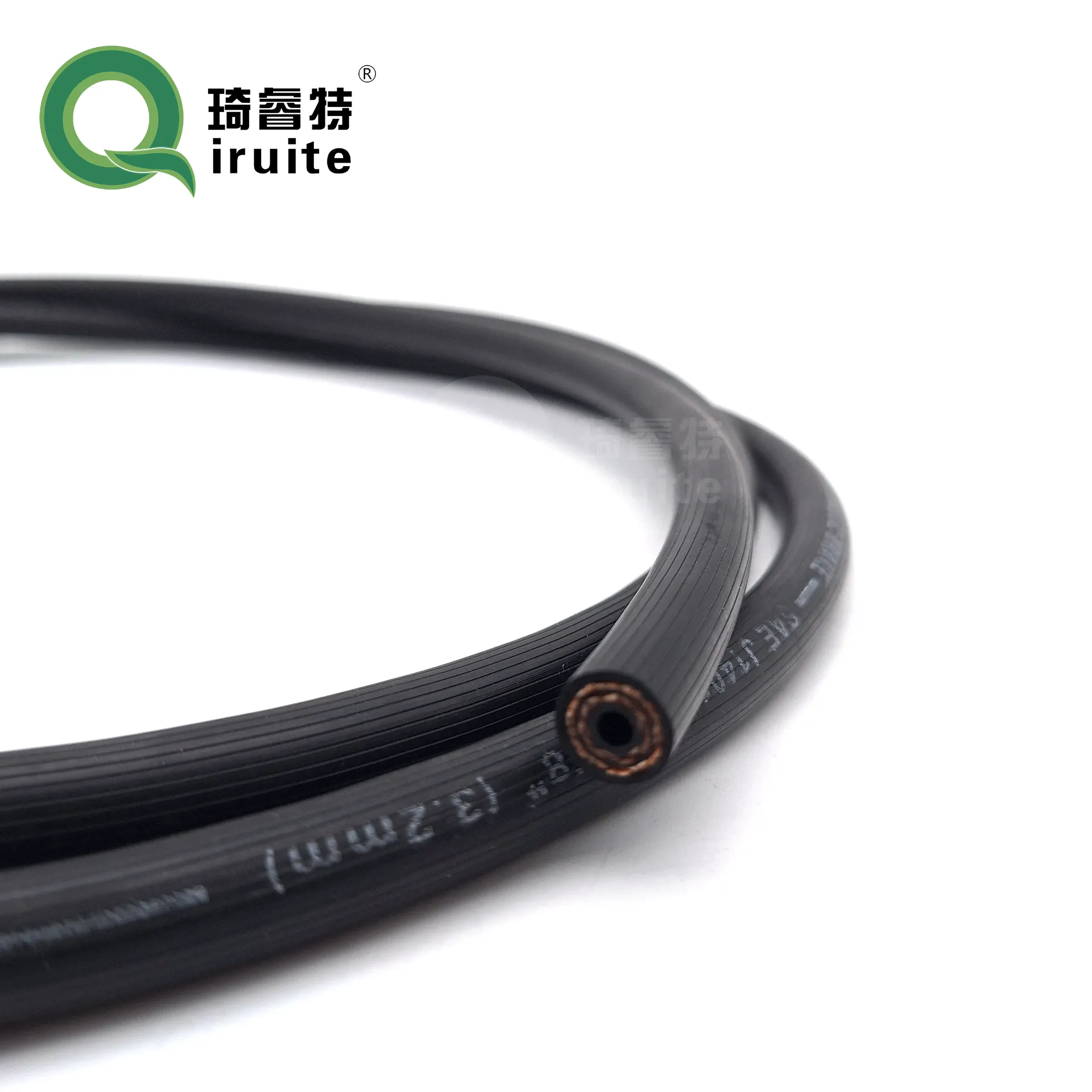

SAE J1401 Brake Hose

Navigating the intricacies of plumbing components often involves understanding specific features such as left hand thread pipe couplings. These unique pipe fittings, vital in various industries, offer functionality that stands distinct from regular threads, presenting a mix of safety, precision, and reliability. Understanding these aspects not only boosts expertise but also enhances application in real-world scenarios, ensuring that your projects are built on a foundation of solid knowledge and practical insights.

The application scope of left hand thread pipe couplings extends beyond conventional plumbing into aerospace, automotive, and even high-precision industrial sectors. Industries that involve high vibrational forces or rotation benefit profoundly from these specialized components, underscoring their necessity in specialized engineering solutions. Thus, continuous learning and staying updated with the latest technological advancements in couplings can significantly impact effectiveness and project success rates. In terms of safety, left hand thread couplings play an integral role. Systems utilizing fluids, gases, or hazardous materials can pose higher risks if not secured adequately. Here, the wrong-thread scenario can lead to catastrophic failures. Therefore, understanding the dynamics of left threading—how force distribution and thread direction affect joint integrity—gives professionals an edge, embedding safety deeply into practice. From a trustworthiness perspective, employing left hand thread pipe couplings requires adherence to industry standards and regulations, often dictated by bodies like the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO). Trust is built on the ability to consistently align with these standards, guaranteeing system integrity and safety. In conclusion, left hand thread pipe couplings are more than just an industry-specific product—they are a testament to engineering foresight and the nuanced understanding of mechanical systems. Whether it's enhancing safety in high-risk environments or ensuring precise alignment in complex installations, these couplings offer unique solutions. Mastery in utilizing these components showcases a sharpened expertise that embraces experience, authority, and trust, crucial elements for success in any technical domain. For professionals and businesses alike, leveraging this knowledge not only mitigates risks but also positions projects for long-term efficacy and innovation.

The application scope of left hand thread pipe couplings extends beyond conventional plumbing into aerospace, automotive, and even high-precision industrial sectors. Industries that involve high vibrational forces or rotation benefit profoundly from these specialized components, underscoring their necessity in specialized engineering solutions. Thus, continuous learning and staying updated with the latest technological advancements in couplings can significantly impact effectiveness and project success rates. In terms of safety, left hand thread couplings play an integral role. Systems utilizing fluids, gases, or hazardous materials can pose higher risks if not secured adequately. Here, the wrong-thread scenario can lead to catastrophic failures. Therefore, understanding the dynamics of left threading—how force distribution and thread direction affect joint integrity—gives professionals an edge, embedding safety deeply into practice. From a trustworthiness perspective, employing left hand thread pipe couplings requires adherence to industry standards and regulations, often dictated by bodies like the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO). Trust is built on the ability to consistently align with these standards, guaranteeing system integrity and safety. In conclusion, left hand thread pipe couplings are more than just an industry-specific product—they are a testament to engineering foresight and the nuanced understanding of mechanical systems. Whether it's enhancing safety in high-risk environments or ensuring precise alignment in complex installations, these couplings offer unique solutions. Mastery in utilizing these components showcases a sharpened expertise that embraces experience, authority, and trust, crucial elements for success in any technical domain. For professionals and businesses alike, leveraging this knowledge not only mitigates risks but also positions projects for long-term efficacy and innovation.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025