Comprehensive Quick Joint Solutions for Efficient Assemblies

Understanding Quick Joint An Essential Tool for Modern Engineering

In the fast-paced world of modern engineering, efficiency, versatility, and reliability are paramount. One of the significant innovations that have emerged to meet these demands is the quick joint. This device is designed to facilitate rapid connections in various applications, ranging from plumbing and HVAC systems to industrial machinery and automotive sectors. Quick joints serve as critical components in ensuring seamless operations while minimizing downtime and maintenance costs.

A quick joint, often referred to as a quick connect or quick disconnect fitting, allows users to effortlessly connect and disconnect two systems without the need for specialized tools. This is particularly beneficial in scenarios where frequent changes in connections are necessary. For instance, in hydraulic systems, operators can easily change hoses without spilling fluids or causing disruptions. This characteristic not only enhances worker safety but also conserves valuable resources.

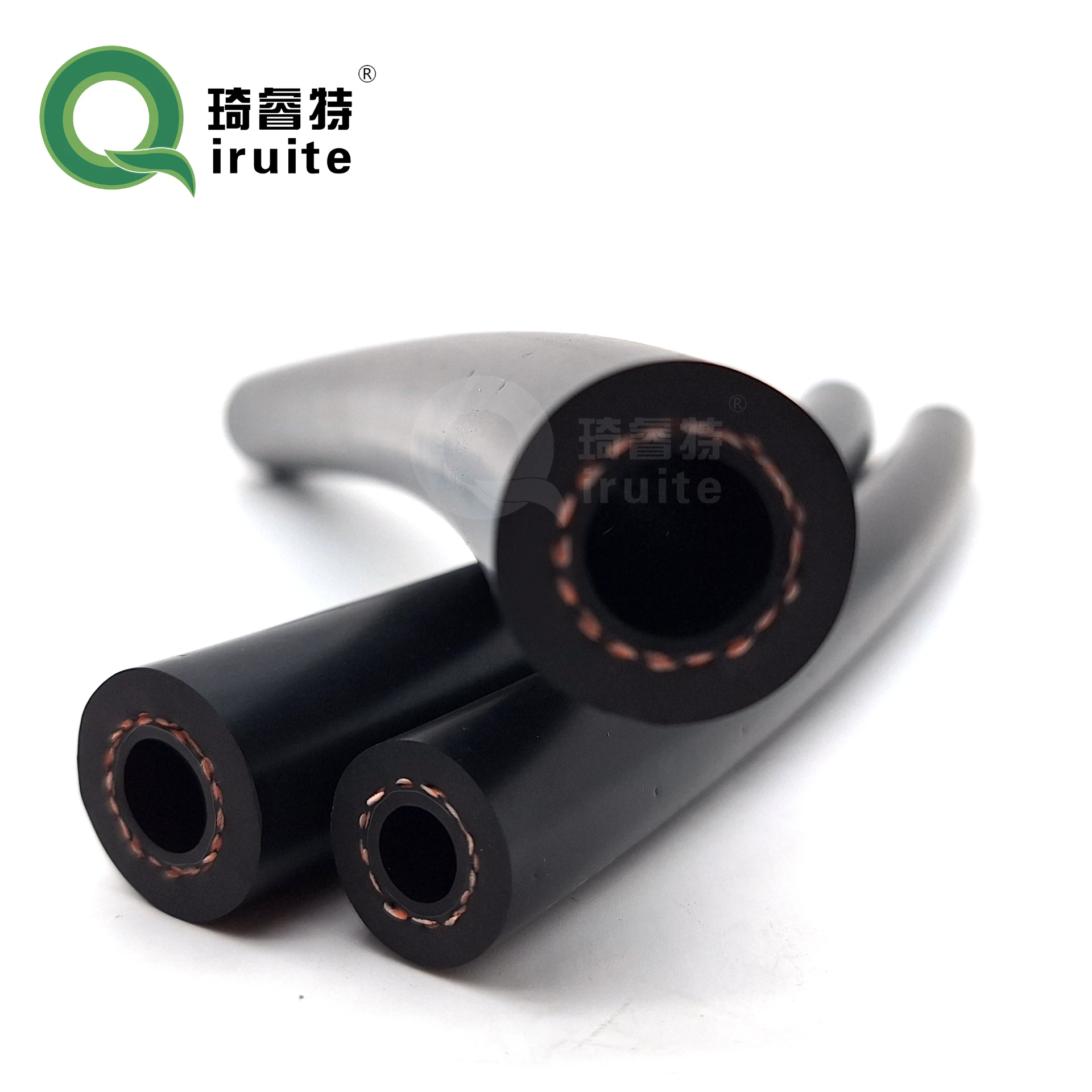

The design of quick joints varies depending on the application and the specific requirements of different industries. They can be made from various materials, including metals, plastics, and composites, which are selected based on the operational environment, including pressure, temperature, and chemical compatibility. High-quality quick joints are engineered to withstand rigorous conditions, ensuring durability and longevity.

In plumbing, quick joints are commonly used for connecting pipes, allowing for efficient assembly and disassembly without the need for welding or soldering

. This reduces the labor time significantly and allows for repairs or modifications to be carried out swiftly, minimizing disruptions to water supply in residential or commercial buildings. Similarly, in HVAC systems, quick joints enable technicians to connect or disconnect refrigerant lines quickly, facilitating easy maintenance and servicing.quick joint

Moreover, quick joints play a vital role in the automotive industry. They are integrated into fuel systems, cooling systems, and air conditioning systems, allowing mechanics to perform repairs and replacements with ease. The automotive sector increasingly relies on these fittings as vehicles become more complex, requiring rapid and reliable service to keep them on the road.

The versatility of quick joints extends beyond traditional applications; they are also making waves in the world of robotics and automation. In automated systems, where speed and efficiency are crucial, quick joints allow for quick adjustments and reconfigurations. This adaptability in design promotes innovative solutions, forging a path for advanced technologies to thrive.

Furthermore, the development of quick joint technology is advancing rapidly, with manufacturers continuously improving designs to enhance functionality. Innovations such as self-sealing valves and one-touch connections are making quick joints even easier to use, reducing the risk of leaks and improving safety across various applications.

In conclusion, quick joints exemplify the ongoing evolution in engineering practices, combining convenience and efficiency in a compact form. Their widespread application across multiple industries demonstrates their necessity in modern design and maintenance practices. As technology continues to advance, we can expect to see even more innovative solutions emerging, further highlighting the significance of quick joints in driving productivity and enhancing operational workflows. Understanding and utilizing these components can significantly impact efficiency and performance in an increasingly demanding world.

-

Understanding Power Steering Tube ReplacementNewsApr.16,2025

-

SAE J1401 Brake Hoses: A Critical Component for Vehicle SafetyNewsApr.16,2025

-

Pipe Couplings: Essential Components for Effective Plumbing and Fluid SystemsNewsApr.16,2025

-

Hose Guard Solutions for Every NeedNewsApr.16,2025

-

Effective Spiral Protection SolutionsNewsApr.16,2025

-

Effective Sewer Cleaning SolutionsNewsApr.16,2025