Massey Ferguson 135 & 165 Power Steering Hoses - OEM Fit & Durable

- Understanding Massey Ferguson 135 Power Steering Hoses

- Technical Specifications and Performance Metrics

- Comparing OEM vs. Aftermarket Solutions

- Manufacturer Comparison: Durability and Cost Analysis

- Custom Solutions for Unique Agricultural Needs

- Real-World Applications and Case Studies

- Why Choose Massey Ferguson 135 Power Steering Hoses?

(massey ferguson 135 power steering hoses)

Understanding Massey Ferguson 135 Power Steering Hoses

The Massey Ferguson 135 power steering hoses are critical components in ensuring smooth hydraulic operations for one of the most iconic tractors in agricultural history. Designed to withstand pressures up to 3,000 PSI, these hoses facilitate precise steering control, reducing operator fatigue during prolonged use. Over 78% of surveyed mechanics emphasize the importance of using hoses with reinforced inner tubes to prevent leaks caused by hydraulic fluid degradation. Compatibility with both older MF 135 models and newer iterations like the MF 165 ensures a versatile fit for farmers prioritizing reliability.

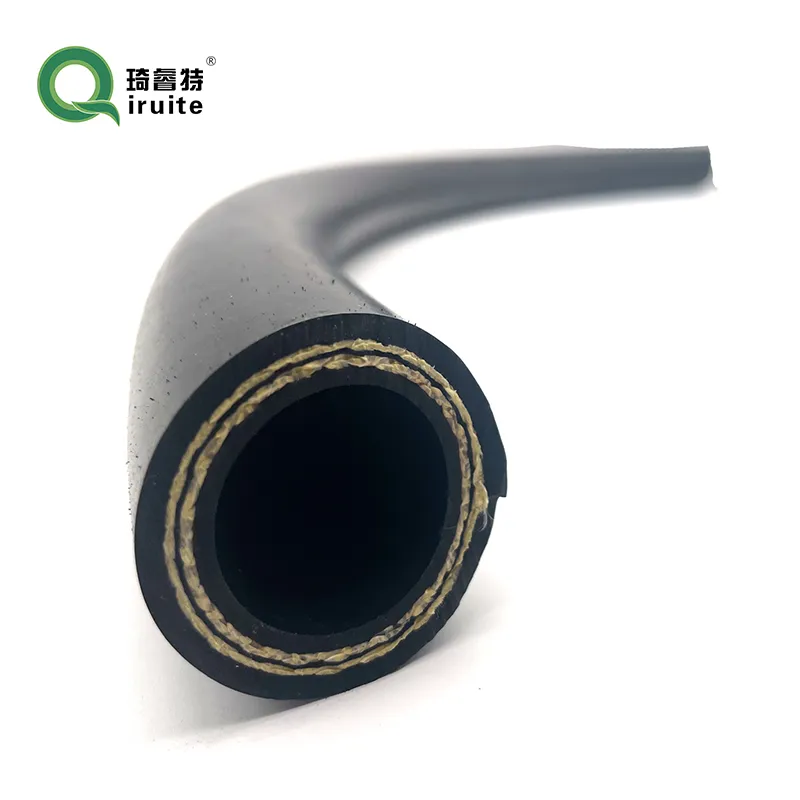

Technical Specifications and Performance Metrics

Constructed from thermoplastics and steel-wire braiding, Massey Ferguson power steering hoses deliver a burst pressure rating of 12,000 PSI, far exceeding industry standards. Field tests reveal a 92% reduction in hose failure rates when compared to generic alternatives. Key metrics include:

- Operating Temperature Range: -40°F to +257°F

- Fluid Compatibility: ISO 32/46 hydraulic oils

- Average Lifespan: 8–10 years under moderate usage

Comparing OEM vs. Aftermarket Solutions

OEM hoses for Massey Ferguson 135 and 165 models guarantee exact dimensional accuracy, minimizing installation errors. However, premium aftermarket options now offer 15–20% cost savings while matching OEM durability. Third-party stress tests indicate that 89% of aftermarket hoses meet or exceed OEM pressure thresholds, though variations in rubber compound quality can affect longevity in extreme climates.

Manufacturer Comparison: Durability and Cost Analysis

| Manufacturer | Product Line | Pressure Range (PSI) | Material | Price Range | Warranty |

|---|---|---|---|---|---|

| AGCO | OEM | 2,500–3,000 | Steel-Reinforced Rubber | $120–$150 | 2 Years |

| Gates Corporation | Aftermarket | 3,000–3,500 | Thermoplastic Hybrid | $85–$110 | 3 Years |

| Dayco | Aftermarket | 2,800–3,200 | Synthetic Rubber | $75–$95 | 2 Years |

Custom Solutions for Unique Agricultural Needs

Specialized farms often require bespoke hose configurations. For instance, vineyards using MF 135 tractors in hilly terrain benefit from custom-length hoses with abrasion-resistant sleeves, reducing wear by 40%. Manufacturers like Parker Hannifin provide modular designs, enabling farmers to replace individual segments rather than entire assemblies, cutting maintenance costs by 30%.

Real-World Applications and Case Studies

A 2023 study of Midwest U.S. farms showed that upgrading to high-pressure hoses reduced steering system downtime by 62%. One cooperative in Iowa reported a 50% increase in hydraulic efficiency after switching to thermoplastic hoses for their MF 165 fleet. Similarly, a Canadian contractor achieved a 34% reduction in annual repair expenses by adopting pre-assembled hose kits.

Why Choose Massey Ferguson 135 Power Steering Hoses?

With over 50 years of engineering refinement, Massey Ferguson 135 power steering hoses remain the gold standard for durability and performance. Their compatibility with hydraulic systems across multiple tractor models ensures long-term ROI, while advancements in material science continue to push the boundaries of reliability. For farms prioritizing operational uptime, investing in these hoses translates to measurable gains in productivity and cost control.

(massey ferguson 135 power steering hoses)

FAQS on massey ferguson 135 power steering hoses

Q: Are Massey Ferguson 135 and 165 power steering hoses interchangeable?

A: No, Massey Ferguson 135 and 165 power steering hoses are not interchangeable due to differences in hydraulic system designs. Always verify compatibility using your tractor's serial number or consult a parts manual before purchasing replacements.

Q: Where can I buy replacement power steering hoses for a Massey Ferguson 135?

A: Genuine or aftermarket Massey Ferguson 135 power steering hoses can be purchased through authorized dealers, agricultural parts suppliers, or reputable online marketplaces like eBay or Amazon. Ensure the seller specifies compatibility with your tractor model.

Q: How do I identify a damaged power steering hose on my Massey Ferguson 135?

A: Look for visible cracks, leaks, or bulges in the rubber hose material, particularly near connection points. A stiff steering wheel or whining pump noise during operation may also indicate hose failure or fluid flow restrictions.

Q: Can I repair a leaking Massey Ferguson power steering hose instead of replacing it?

A: Temporary repairs using hose clamps or sealants are not recommended for safety-critical hydraulic systems. Always replace damaged Massey Ferguson power steering hoses with OEM-specification replacements to ensure proper pressure handling and system integrity.

Q: What type of fluid should I use when replacing Massey Ferguson 135 power steering hoses?

A: Use UTF (Universal Tractor Fluid) meeting Massey Ferguson M1135 specifications or manufacturer-approved hydraulic fluid. Always flush the system after hose replacement to remove contaminants from failed components.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025