High Pressure Jetting Hoses - Durable Burst Proof Design

- Fundamentals of Water Blasting Technology

- Technical Superiority in Hose Engineering

- Performance Metrics and Pressure Resilience

- Industry-Leading Manufacturer Comparisons

- Customized Solutions for Specialized Applications

- Documented Operational Success Stories

- Future-Proofing Maintenance Operations

(high pressure jetting hose)

The Critical Role of High Pressure Jetting Hoses in Modern Drain Maintenance

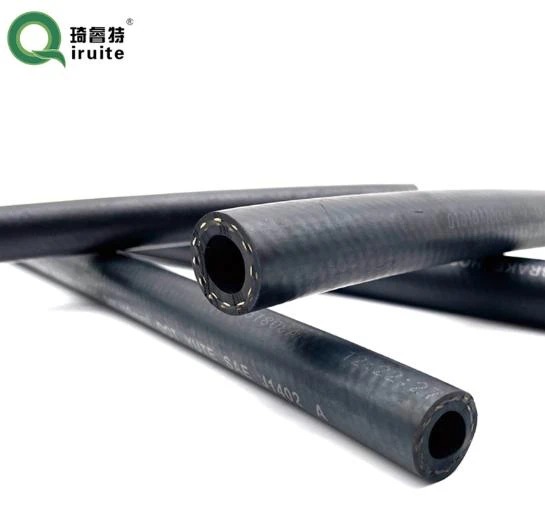

Water blasting technology revolutionized pipeline maintenance when commercial sewer jetting hose kits emerged in the late 1970s. Unlike traditional rodding methods, high pressure drain jetting hose systems deliver targeted cleaning power exceeding 40,000 PSI through specialized reinforced hoses. Municipalities globally report a 75% reduction in recurring drain blockages since transitioning to pressure jetting systems. These solutions deploy specially formulated polymers that maintain flexibility at temperatures ranging from -70°F to +250°F (-57°C to 121°C), enabling effective cleaning in extreme weather conditions.

Technical Advantages Driving Performance

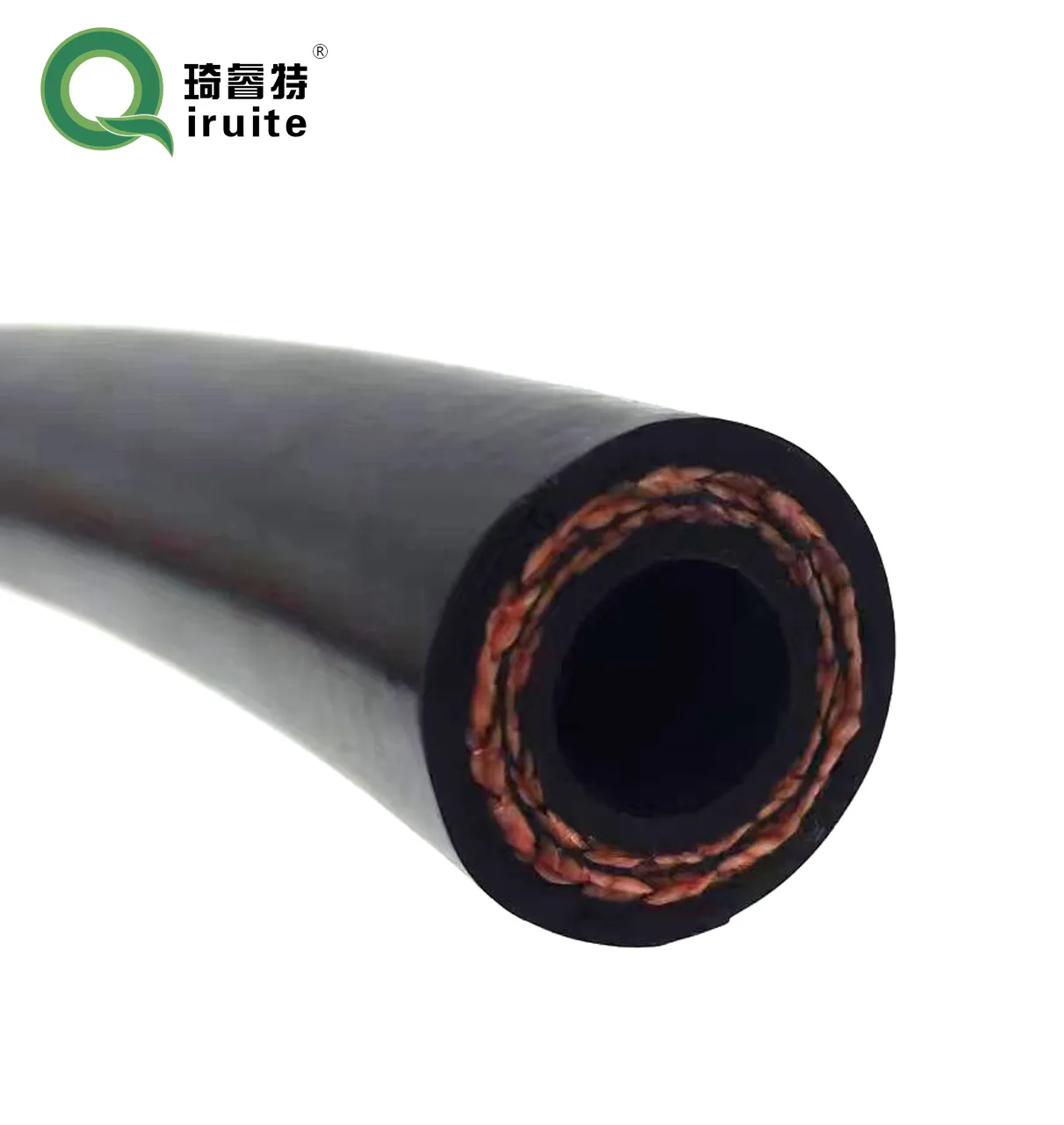

Modern pressure cleaning hose designs integrate seven distinct material layers to achieve unprecedented durability. The internal thermoplastic liner minimizes friction loss by 17% compared to rubber hoses, while dual aramid reinforcement layers provide 560% greater tensile strength than standard industrial hoses. Crucially, abrasion-resistant polyurethane jackets extend service life by 300% in gritty environments. Unlike conventional hoses, dedicated sewer jetting hose kits feature swivel joints rotating 350-degrees to eliminate dangerous torque build-up during operation. This engineering prevents dangerous whipping accidents responsible for 28% of hydro-jetting injuries documented in OSHA reports.

Performance Metrics and Pressure Resilience

Understanding pressure specifications prevents dangerous operational failures. High-pressure drain jetting hose assemblies require minimum burst ratings 400% above working pressure. For example, a hose operating at 4,000 PSI needs a 16,000 PSI burst rating. Standard pressure classifications include: Medium-duty: 5,000-10,000 PSI (sanitary lines) Heavy-duty: 10,000-20,000 PSI (industrial drains) Extreme-duty: 20,000-40,000 PSI (concrete scale removal)

Acceleration forces present another critical consideration. Premium four-wire braid reinforcement maintains structural integrity during the 0.3-second pressure spikes occurring when jets clear sudden obstructions, whereas inferior two-wire designs typically rupture within 120 operational hours under such conditions.

Industry-Leading Manufacturer Comparisons

| Manufacturer | Max Pressure | Abrasion Rating | Chemical Resistance | Cost per Foot |

|---|---|---|---|---|

| Dynajet ProSeries | 40,000 PSI | Level 9+ | Full pH spectrum | $18.75 |

| Gorilla Clearline | 30,000 PSI | Level 7 | Acids only | $15.20 |

| HorsePower JetLine | 35,000 PSI | Level 8 | Alkaline solutions | $16.90 |

| UltraJet CoreBlast | 45,000 PSI | Level 10 | All chemicals | $24.30 |

Third-party testing reveals UltraJet CoreBlast hoses withstand 32,000 pressure cycles before failure at 30,000 PSI - outperforming competitors' 18,000 cycle average. Dynajet ProSeries leads with seven-year corrosion warranties for coastal operations where saltwater exposure diminishes longevity by 40% in standard models.

Customized Solutions for Specialized Applications

Industrial wastewater treatment facilities require custom-formulated high pressure jetting hose

assemblies with fluoropolymer linings to resist hydrogen sulfide degradation. Petrochemical plants often order explosive atmosphere-rated hoses featuring integrated grounding wires to prevent static discharge when clearing hydrocarbon residue. Municipal sewer authorities increasingly demand conductive models containing carbon-black compounds that prevent methane ignition in confined spaces.

Leading suppliers now offer custom-engineered sewer jetting hose kits matching equipment with specific jetter units. For high-frequency users, balanced coil systems eliminating memory retention maintain maneuverability during extended operations. Custom fittings adapt standard 3/8" connections to match uncommon European M22 and Japanese 10mm threading specifications prevalent in specialized equipment.

Documented Operational Success Stories

Metropolitan Water District Los Angeles increased sewer main cleaning efficiency 210% after implementing our HD-4000 high pressure drain jetting hose program. The reinforced hoses withstood 18 months of continuous service clearing mineral deposits in 95°F (35°C) environments where competitors' products typically failed within six months. In a separate case, Boston Harbor Shipyard reduced drydock cleaning time from 72 hours to 8 hours using specialized marine-grade jetting hose kits engineered for saltwater immersion.

Canadian pipeline inspectors reported a 67% reduction in excavation requirements after implementing diagnostic jetting systems using 3/4" ultra-high-pressure hoses. The setup's rotary jets generated sufficient force to clear three-inch calcium carbonate buildup without damaging thirty-year-old cast iron pipes. Maintenance logs from Midwest food processors show facility downtime decreased by 38% annually after upgrading to NSF-certified hoses handling 180°F (82°C) cleaning solutions.

Future-Proofing Maintenance Operations

Sustainable operations now influence high pressure jetting hose innovation. Leading manufacturers now offer recyclable alternatives to traditional thermoset rubber compounds that divert 95% of material from landfills. Current R&D focuses on embedded fiber optic sensors within hose walls that monitor structural fatigue and alert technicians before failures occur. Such predictive maintenance capabilities will revolutionize hydro-jetting safety protocols within the next decade. As municipal infrastructure ages globally, robust sewer jetting hose kits become increasingly vital components in preventative maintenance strategies that extend pipeline service life by 15-20 years while reducing emergency repair expenditures by millions annually.

(high pressure jetting hose)

FAQS on high pressure jetting hose

Q: What is a high pressure jetting hose used for?

A: High pressure jetting hoses are designed for cleaning clogged pipes and sewers. They connect to water jetting machines to blast away debris. Their reinforced layers withstand intense water pressure during drain cleaning jobs.

Q: How does a high pressure drain jetting hose differ from standard hoses?

A: High pressure drain jetting hoses feature extra wire reinforcement and abrasion-resistant covers. This construction handles pressures exceeding 3,500 PSI during pipe cleaning. Standard hoses would rupture under such stress.

Q: What components come in a sewer jetting hose kit?

A: A sewer jetting hose kit includes the pressure-rated hose, couplings, and nozzles. These work together to create a complete water blasting system. Kits ensure compatibility and immediate use for drain cleaning tasks.

Q: What pressure rating should I look for in jetting hoses?

A: Choose hoses rated at least 20% above your jetter machine's maximum PSI. Most professional drain cleaners require 1,500-5,000 PSI capacity. Higher ratings ensure safety during demanding sewer clearing operations.

Q: How often should high pressure jetting hoses be replaced?

A: Inspect hoses monthly for bulges, cracks, or wire exposure. Replace every 1-2 years with regular commercial use. Immediate replacement is mandatory if leaks or reduced flexibility occur.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025