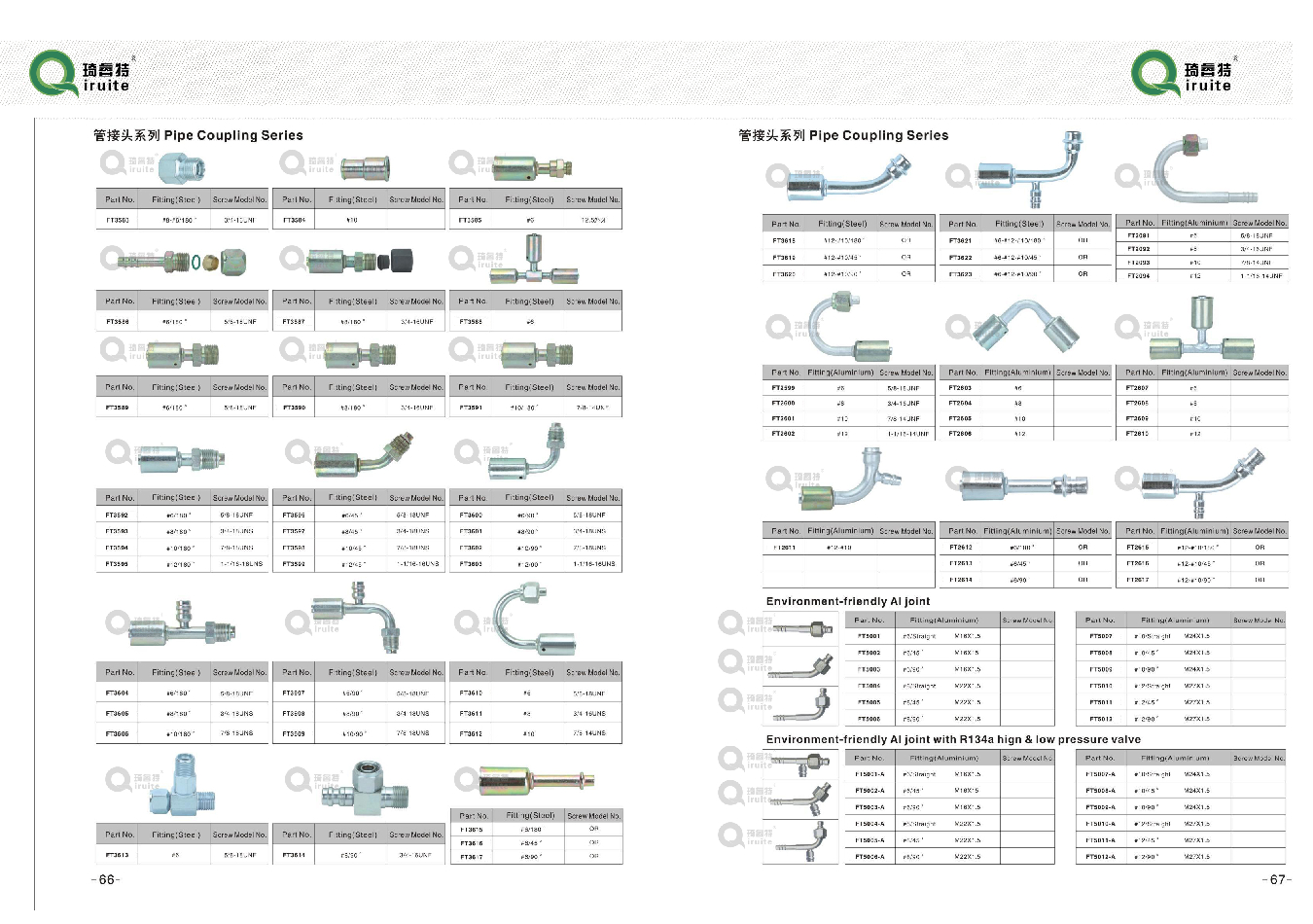

different types of pipe couplings

Different Types of Pipe Couplings A Comprehensive Overview

Pipe couplings are essential components used in the piping industry to connect two or more pipes together. They ensure a tight and reliable connection that can handle various pressures and environmental conditions. Understanding the different types of pipe couplings can aid in selecting the right one for a specific application, ranging from plumbing to industrial and infrastructure projects. Here, we explore several types of pipe couplings, their characteristics, and their typical uses.

1. Socket Weld Couplings

Socket weld couplings are primarily used for piping systems involving high pressures and temperatures. They consist of a pipe section with a female end that can fit over a pipe's male end. The fitting is usually welded in place, creating a strong and permanent connection that is highly resistant to leakage. Socket weld couplings are commonly utilized in chemical processing and power generation applications due to their durability.

2. Threaded Couplings

Threaded couplings are designed for quick and easy pipe connections. These couplings feature male and female threads that can be easily screwed together. They are ideal for situations where pipes may need to be taken apart for maintenance or repairs, making them a popular choice in residential plumbing as well as in various industrial applications. However, it is crucial to ensure proper sealing, typically using Teflon tape or pipe dope, to prevent leaks.

Flanged couplings provide a robust solution for joining large diameter pipes, especially in water supply and piping systems where high flow rates are necessary. These couplings consist of a flat piece of metal (the flange) that is bolted to another flange on a different pipe section. Flanged connections allow for easy disassembly and are ideal for systems that require regular maintenance or inspection.

different types of pipe couplings

4. Compression Couplings

Compression couplings are often used in systems that require flexibility to accommodate pipe movement due to thermal expansion or contraction. These couplings work by compressing a rubber or elastomeric gasket that creates a seal between the pipes. They are easy to install and do not require welding or soldering, making them popular in residential plumbing applications and gas lines.

5. Flexible Couplings

Flexible couplings are designed to accommodate pipe misalignment and movement, making them suitable for applications where pipes may vibrate or shift. These couplings usually include a rubber element that allows for flexibility while maintaining a secure connection. Commonly seen in plumbing and HVAC systems, flexible couplings help to prevent stress on the pipes and reduce the risk of damage.

6. Expansion Couplings

Expansion couplings are specifically engineered to absorb changes in temperature and length caused by thermal expansion. These couplings can accommodate movement in the piping system, reducing stress at joints and extending the life of the pipelines. Expansion couplings are often utilized in long runs of piping, such as steam or hot water systems.

Conclusion

The choice of pipe coupling significantly impacts the efficiency and reliability of piping systems. Each type of coupling serves a unique purpose, and understanding their characteristics is crucial for successful installation and operation. By selecting the appropriate coupling for your specific application, you can ensure a durable, leak-free connection that meets the demands of your piping project. Whether it’s for residential plumbing, industrial applications, or infrastructure development, knowing the different types of pipe couplings will ultimately enhance the integrity of your piping systems.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025