Feb . 05, 2025 05:14

Back to list

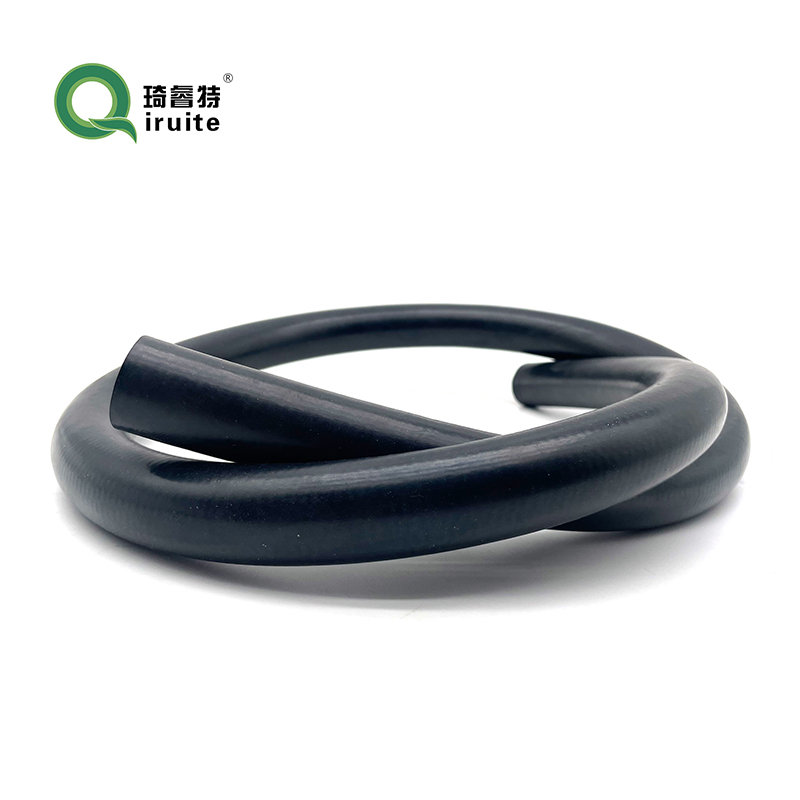

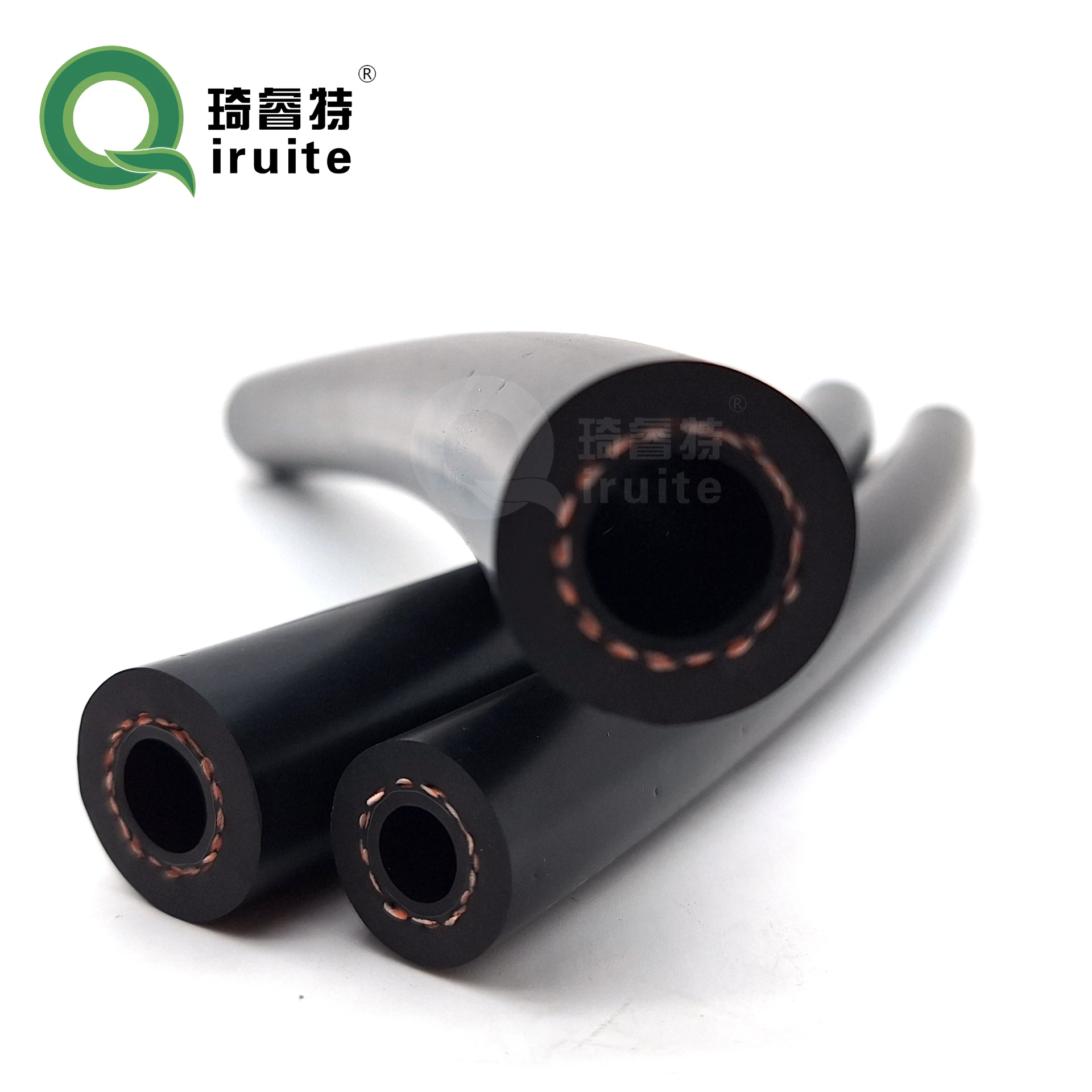

E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE

Air compressor pipe connectors are integral components in pneumatic systems, efficiently ensuring the transfer of compressed air from one point to another. Selecting the right type of connector can vastly impact the performance of an air compressor system, making it important for users to understand their options, relevant connections, and their respective benefits.

The choice of proper pipe connectors also impacts safety. An inappropriate connector can create points of failure within an air compressor system, posing risks of accidents or injuries. Hence, selecting a connector from a reputable manufacturer, with reliable customer reviews and certifications, can offer peace of mind regarding both safety and performance. Expertise in this field involves understanding not just the types and materials of connectors available, but also the specific application needs. For example, in environments with potential chemical exposure, opting for a stainless steel connector would be prudent due to its superior resistant properties. Additionally, the understanding of correct sizing and pressure handling is critical for ensuring optimal performance. While advancements in material science have led to the development of robust, high-performance connectors, staying updated with these innovations is crucial. Subtle improvements can lead to significant benefits in terms of efficiency, longevity, and safety. Establishing trust in this sphere revolves around the consistent performance of either the connectors or the system as a whole. Emphasizing the importance of investing in quality from the onset protects the system against unnecessary downtimes and repairs. When customers experience fewer service disruptions and achieve longer lifespans on their systems, the reliability of pipe connectors is underscored, solidifying the credibility of experts' recommendations. In conclusion, air compressor pipe connectors, though small in size, have a substantial impact on the effectiveness and safety of pneumatic systems. A well-informed decision, supported by an understanding of material benefits, connector types, and proper maintenance practices, ensures operational success. Such decisions can foster a sense of confidence in not just the components used, but also in the system's capacity to deliver optimal results, thereby reinforcing customer trust and satisfaction.

The choice of proper pipe connectors also impacts safety. An inappropriate connector can create points of failure within an air compressor system, posing risks of accidents or injuries. Hence, selecting a connector from a reputable manufacturer, with reliable customer reviews and certifications, can offer peace of mind regarding both safety and performance. Expertise in this field involves understanding not just the types and materials of connectors available, but also the specific application needs. For example, in environments with potential chemical exposure, opting for a stainless steel connector would be prudent due to its superior resistant properties. Additionally, the understanding of correct sizing and pressure handling is critical for ensuring optimal performance. While advancements in material science have led to the development of robust, high-performance connectors, staying updated with these innovations is crucial. Subtle improvements can lead to significant benefits in terms of efficiency, longevity, and safety. Establishing trust in this sphere revolves around the consistent performance of either the connectors or the system as a whole. Emphasizing the importance of investing in quality from the onset protects the system against unnecessary downtimes and repairs. When customers experience fewer service disruptions and achieve longer lifespans on their systems, the reliability of pipe connectors is underscored, solidifying the credibility of experts' recommendations. In conclusion, air compressor pipe connectors, though small in size, have a substantial impact on the effectiveness and safety of pneumatic systems. A well-informed decision, supported by an understanding of material benefits, connector types, and proper maintenance practices, ensures operational success. Such decisions can foster a sense of confidence in not just the components used, but also in the system's capacity to deliver optimal results, thereby reinforcing customer trust and satisfaction.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025