1 2 threaded pipe coupling

Understanding 1% Threaded Pipe Coupling A Comprehensive Overview

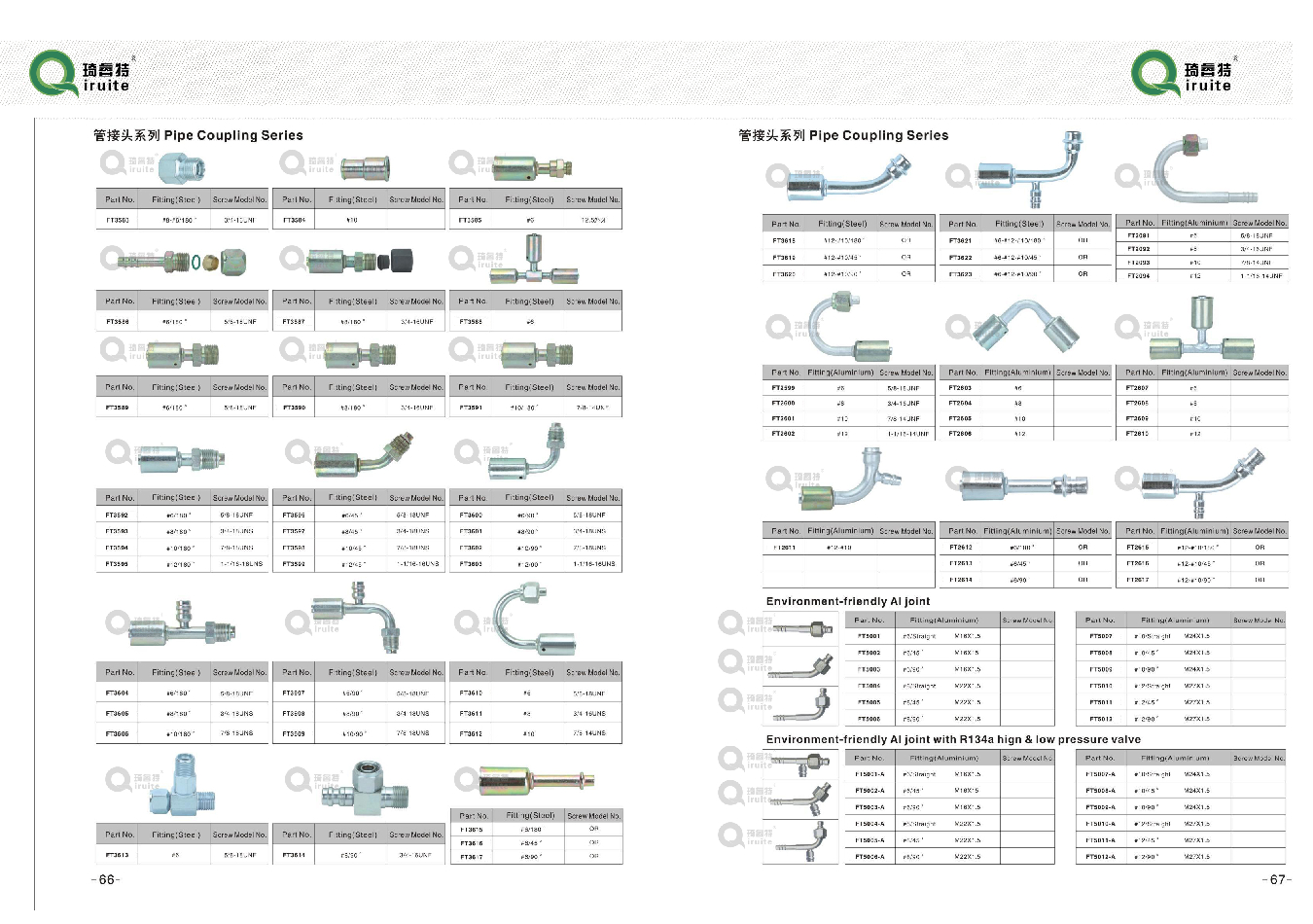

The 1% threaded pipe coupling is a crucial component in various plumbing and piping systems, designed to create secure and leak-proof connections between sections of pipes. In industrial, commercial, and residential settings, maintaining a reliable flow of fluids is essential, and this coupling plays a significant role in achieving that goal.

Typically made from durable materials such as steel, brass, or plastic, the 1% threaded pipe coupling is designed to withstand high pressures and corrosive environments. Its threading allows for easy assembly and disassembly, making it a preferred choice for installations where frequent maintenance might be necessary. The 1% designation often refers to the tolerance or variation in the thread specifications, ensuring a precise fit and reliable performance.

The Importance of Proper Installation

The effectiveness of a 1% threaded pipe coupling relies heavily on proper installation techniques. When installing, it’s crucial to clean the threads of both the coupling and the pipe ends to avoid any debris interference, which could lead to leaks. Additionally, applying thread sealant or tape is recommended to enhance the sealing capabilities and further prevent potential leaks. Tightening should be done carefully, ensuring not to overtighten, which can damage the threads and compromise the integrity of the connection.

Applications of 1% Threaded Pipe Couplings

1 2 threaded pipe coupling

1% threaded pipe couplings are utilized in a variety of applications. In residential plumbing, they are commonly used to connect water supply lines, drainage systems, and heating installations. Their versatility extends to the industrial sector, where they facilitate the transportation of liquids, gases, and chemicals, ensuring that systems operate efficiently and safely.

In HVAC systems, these couplings are instrumental in connecting ductwork or piping, allowing for the effective movement of air or refrigerants. Moreover, in oil and gas industries, where high-pressure systems are integral, the reliability of a 1% threaded pipe coupling is paramount to prevent system failures that can lead to costly downtimes and safety hazards.

Advantages of Using 1% Threaded Pipe Couplings

One of the primary advantages of using 1% threaded pipe couplings is their adaptability. They can accommodate various pipe sizes and types, making them suitable for both new installations and repairs in existing systems. Their ease of installation and maintenance means that downtime can be minimized, enhancing operational efficiency.

In summary, the 1% threaded pipe coupling serves as an indispensable part of modern piping systems. Its ability to provide a secure connection while allowing for ease of maintenance makes it a favorite among plumbers and engineers alike. Whether in residential, industrial, or commercial applications, understanding the significance and proper use of 1% threaded pipe couplings ensures a reliable and efficient plumbing system. As plumbing technology continues to advance, the development of even more durable and user-friendly couplings can be anticipated, further enhancing the safety and efficiency of fluid transportation.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025