Exploring the Features and Benefits of J2064 Hose in Automotive Applications

Understanding J2064 Hose An Overview of a Critical Component

In the vast world of automotive and mechanical engineering, various components play crucial roles in ensuring performance, safety, and efficiency. One such essential component is the J2064 hose, a significant part of the automotive industry that often goes unnoticed by the average consumer. Understanding its purpose, applications, and the technology behind it can help shed light on its importance in vehicle performance and reliability.

What is J2064 Hose?

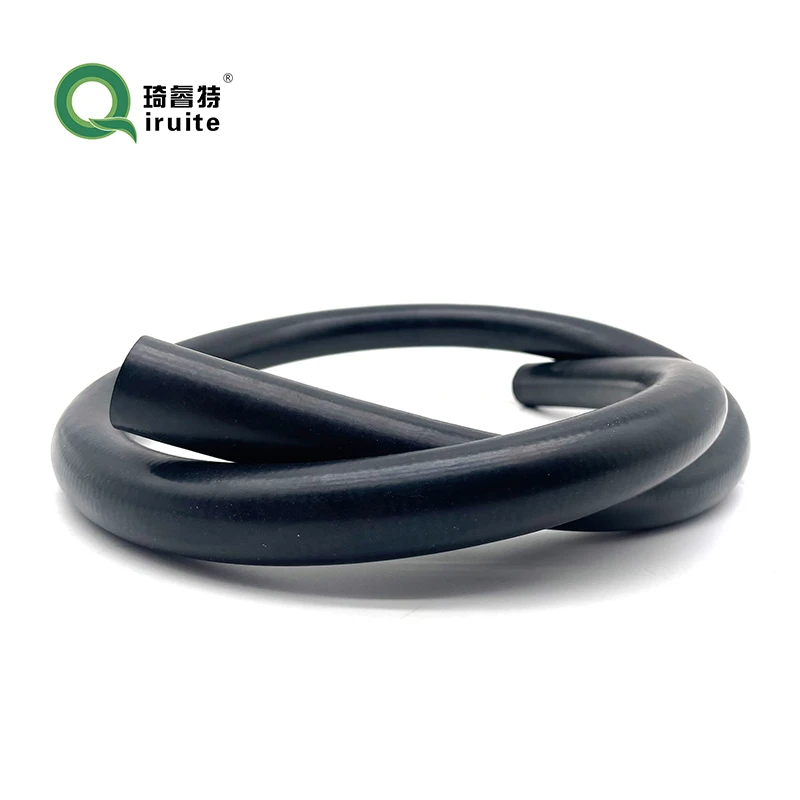

J2064 refers to a specific standard developed by the Society of Automotive Engineers (SAE) for automotive refrigerant hoses. These hoses are primarily designed to handle refrigerants used in air conditioning systems within vehicles. The standard itself is vital as it sets the benchmarks for performance, durability, and safety for the hoses, ensuring that they can withstand the unique conditions present in automotive applications.

Key Features of J2064 Hose

The J2064 hoses come equipped with several noteworthy features that make them ideal for automotive use

1. Temperature and Pressure Resistance J2064 hoses are engineered to perform under high pressures and extreme temperatures, typically ranging from -30°C to 150°C. This resilience allows them to function effectively in various climates and conditions, ensuring the reliability of vehicle air conditioning systems.

2. Compatibility with Refrigerants These hoses are designed to be compatible with the various types of refrigerants utilized in modern vehicles, including R-134a and R-1234yf. This compatibility is crucial as the incorrect material can lead to failures and leaks, which can endanger both the vehicle and its occupants.

3. Durability Constructed using reinforced materials, J2064 hoses resist abrasion, ozone degradation, and chemical exposure, contributing to their longevity. This durability is particularly important in an automotive environment where hoses are subjected to constant movement and varying environmental factors.

4

. Flexibility Despite their rugged construction, these hoses maintain a degree of flexibility that allows for easier installation and routing within tight spaces of engine compartments, enhancing overall vehicle design and efficiency.j2064 hose

Applications of J2064 Hose

The primary application of J2064 hoses is in automotive air conditioning systems, where they act as the conduit for refrigerants, aiding in heat exchange processes essential for cabin cooling. However, their role is not limited to air conditioning; they are also utilized in a range of other applications, including refrigeration and industrial machinery where similar environmental conditions exist.

1. Automobiles The J2064 hoses are extensively used in cars, trucks, and SUVs, ensuring that their air conditioning systems operate efficiently and effectively.

2. Commercial Vehicles In buses, delivery trucks, and large machinery, maintaining a comfortable temperature for passengers and operators is vital. J2064 hoses are pivotal in ensuring these systems function correctly.

3. Refrigeration Systems Beyond the automotive industry, these hoses find applications within commercial and industrial refrigeration systems, supporting smooth operations in various settings.

Importance of Regular Maintenance

While J2064 hoses are designed for durability and resilience, regular maintenance remains crucial. Over time, wear and tear can occur, which may lead to performance issues or failures. Vehicle owners and mechanics must inspect these hoses periodically for signs of cracks, leaks, or other damages to prevent costly repairs or safety hazards.

Conclusion

In conclusion, the J2064 hose is a vital component in the automotive industry that plays a significant role in the efficacy of air conditioning systems. Its designed features ensure that it meets the demanding requirements of modern vehicles, offering durability, flexibility, and compatibility with various refrigerants. Understanding the importance of this component can help vehicle owners appreciate the technology that keeps their rides comfortable and safe. Regular maintenance of these hoses can further enhance their lifespan and performance, ultimately contributing to the overall efficiency of automotive systems.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025