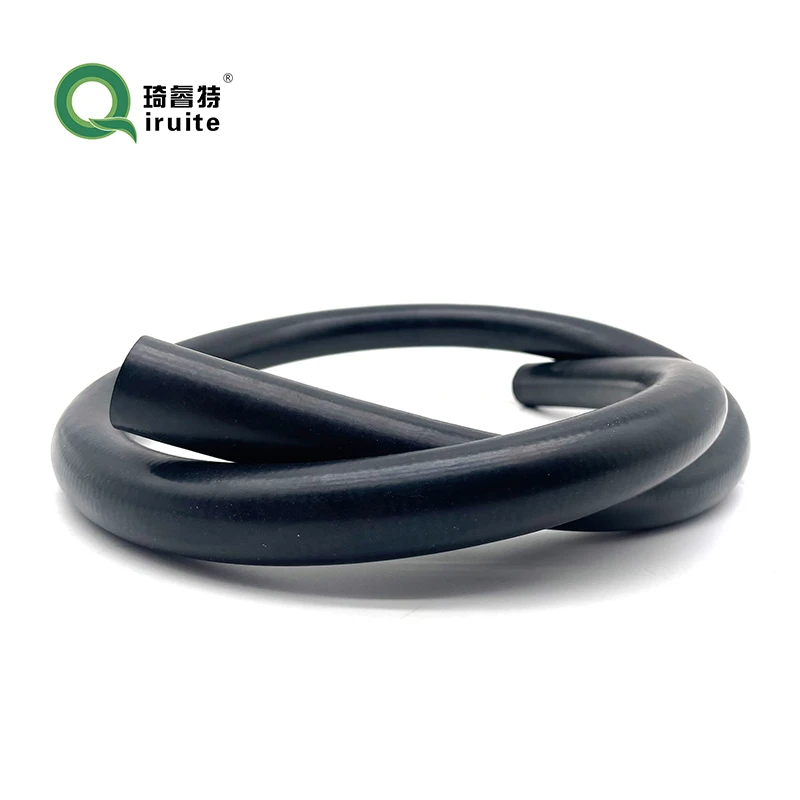

metal hose protector

The Importance of Metal Hose Protectors

In industries ranging from manufacturing to construction, machinery often relies on hoses to transport fluids, gases, or even materials. However, these hoses are susceptible to wear and tear from harsh environments, high temperatures, and physical abrasions. This is where metal hose protectors come into play, providing an essential layer of defense to ensure longevity and efficiency in operations.

Metal hose protectors are designed to shield flexible hoses from various forms of damage, significantly extending their service life and reliability. One of the main materials used in manufacturing these protectors is stainless steel, which offers excellent resistance to corrosion and rust. This characteristic is particularly valuable in environments where humidity or chemical exposure is a concern, such as in oil refineries or chemical processing plants.

One of the key advantages of using metal hose protectors is their ability to withstand extreme temperatures. Many industrial processes involve high heat, which can quickly degrade standard rubber or plastic hoses. Metal protectors not only endure these temperatures but also help to maintain the integrity of the hose beneath, enabling safe and consistent operation. For example, in high-stress applications such as steam or hot water transfer, the right metal hose protector can prevent dangerous ruptures that could lead to workplace accidents.

metal hose protector

Additionally, metal hose protectors can prevent physical damage from external factors

. In environments where hoses are exposed to heavy machinery, foot traffic, or sharp objects, metal protectors act as a buffer, reducing the likelihood of cuts, abrasions, or crushing incidents. This is particularly critical in sectors like construction and mining, where equipment operates in confined spaces with a high risk of accidental damage.Another important aspect of metal hose protectors is their contribution to safety in the workplace. Leaking fluids or gases can pose significant risks, including fire hazards and exposure to harmful substances. By reinforcing hoses with metal protectors, businesses can help ensure that any potential leaks are minimized, protecting both employees and the environment. Regular inspections and maintenance of these protectors also facilitate the early detection of wear, further enhancing operational safety.

Moreover, metal hose protectors are often designed with ease of installation and adaptability in mind. Many come with adjustable clamps or modular components, allowing for quick removal and reattachment as needed. This adaptability makes them suitable for a wide range of applications, from small workshops to large industrial setups.

In conclusion, the value of metal hose protectors cannot be overstated. By providing enhanced durability, temperature resistance, physical protection, and overall safety, they play a vital role in the efficiency and reliability of industrial operations. Investing in high-quality metal hose protectors not only safeguards your equipment but also contributes to a safer, more productive workplace. As industries continue to evolve, prioritizing the protection of critical components like hoses will be essential for maintaining operational excellence.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025