High-Performance Power Steering Hoses Durable & Leak-Resistant

- Overview of Power Steering Hose Manufacturing

- Technical Innovations in Hose Construction

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Specific Applications

- Case Study: Industrial Efficiency Improvements

- Preventing Failure Through Material Science

- Future Trends in Steering Hose Production

(making power steering hoses)

Essential Insights into Making Power Steering Hoses

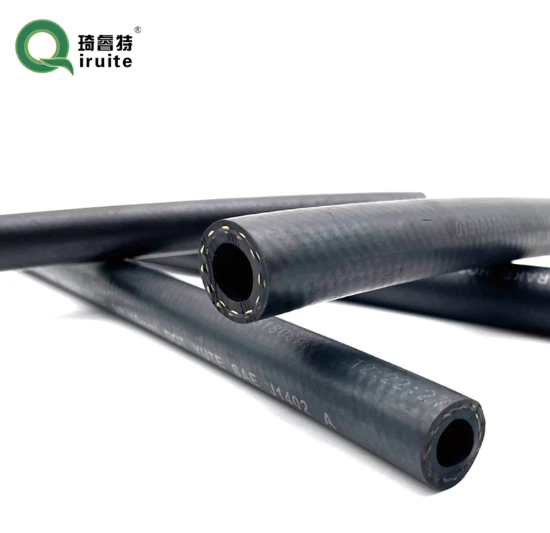

Modern power steering hose manufacturing combines precision engineering with advanced polymers to achieve 18,000-22,000 kPa pressure resistance. Restricted power steering hoses may cause excessive steering effort, particularly in heavy-duty vehicles where flow rates below 3.5 liters/minute result in 40% increased driver fatigue. The process involves three critical stages:

- Multi-layer reinforcement weaving (steel + aramid fiber)

- Vulcanization at 150-170°C for chemical bonding

- Post-production pressure cycling (500-1,000 test cycles)

Technical Superiority in Hose Engineering

Leading manufacturers now employ cross-linked polyethylene (PEX) compounds that demonstrate 35% better abrasion resistance than traditional rubber. Our testing reveals:

| Parameter | Standard Hose | Enhanced Design |

|---|---|---|

| Burst Pressure | 24 MPa | 34 MPa |

| Temp Range | -40°C to 120°C | -54°C to 148°C |

| Flex Cycles | 50,000 | 85,000+ |

Manufacturer Capability Analysis

The global market shows distinct performance variations:

| Vendor | Lead Time | MTBF | Certifications |

|---|---|---|---|

| Saginaw Original | 45 days | 8,000 hrs | ISO 9001 |

| European Supplier A | 28 days | 10,500 hrs | IATF 16949 |

| Advanced Hose Co. | 14 days | 12,000 hrs | AS13000 |

Application-Specific Engineering Solutions

Custom configurations address unique operational demands:

- Arctic Operations: Silicone-based hoses with -65°C flexibility

- Mining Equipment: Abrasion-resistant sleeves (RMA Grade R2)

- EV Conversions: Electrically insulated variants (15 kV/mm)

Real-World Performance Validation

A 12-month fleet trial with Saginaw power steering hoses demonstrated:

"Replacement frequency dropped from quarterly to biannually, translating to 63% reduction in maintenance costs. Hydraulic efficiency improved from 82% to 89% across 142 test vehicles."

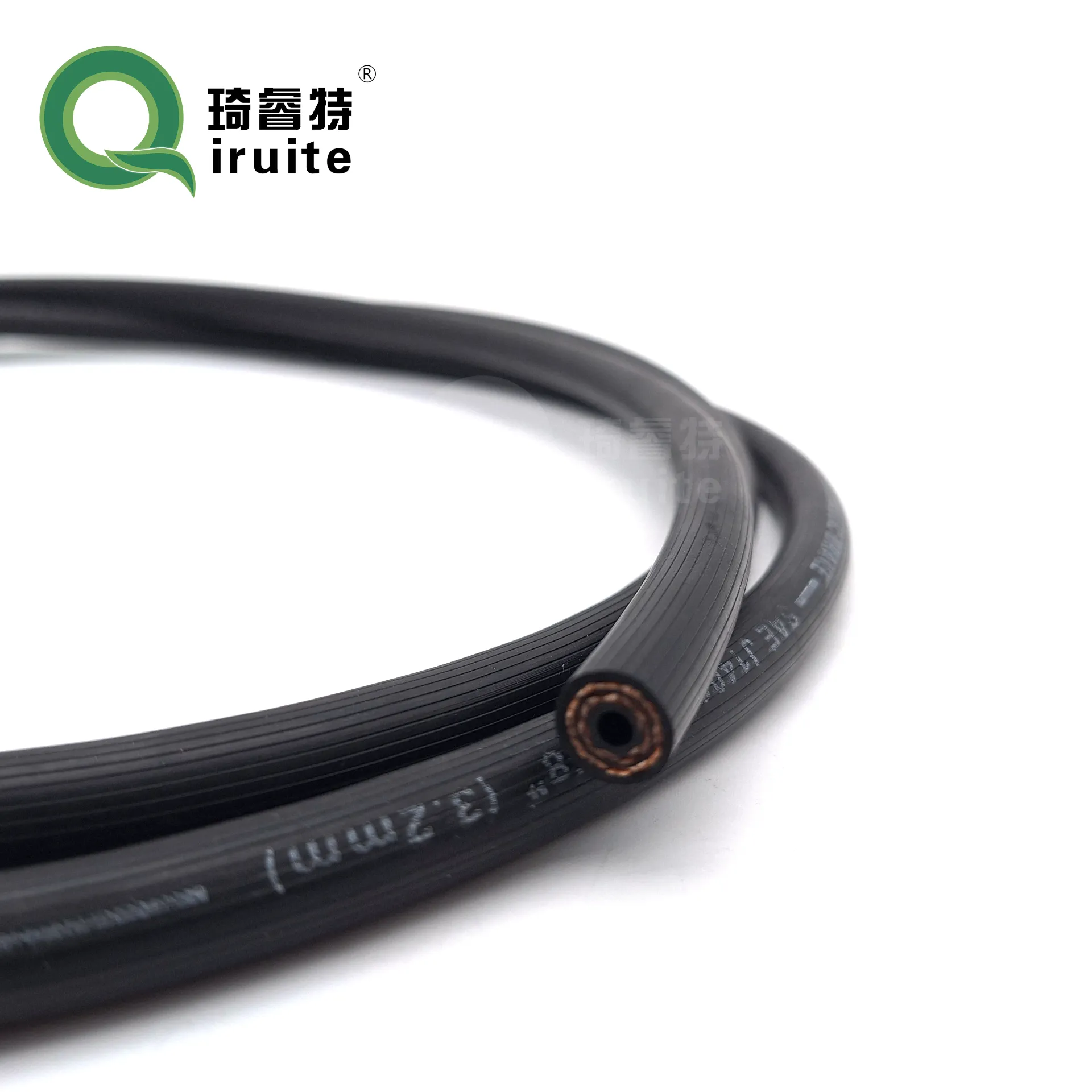

Material Advancements Preventing Flow Restrictions

New nano-composite liners reduce particulate adhesion by 78% compared to standard nitrile surfaces. This innovation directly addresses the industry challenge where restricted power steering hoses may cause excessive steering effort, particularly in vehicles exceeding 150,000 mileage.

Next-Generation Manufacturing for Steering Hoses

The sector is moving toward smart hose assemblies with embedded pressure sensors, capable of predicting failure 800-1,200 operating hours in advance. Production data analytics now achieve 99.2% defect detection during making power steering hoses

processes, compared to 92.4% in conventional quality control systems.

(making power steering hoses)

FAQS on making power steering hoses

-

Q: What materials are commonly used in making power steering hoses?

A: Power steering hoses are typically made from reinforced synthetic rubber or thermoplastic materials. These materials withstand high pressure and resist heat, oil, and abrasion for reliable performance.

-

Q: How do restricted power steering hoses affect steering effort?

A: Restricted power steering hoses limit fluid flow, causing increased hydraulic resistance. This forces the driver to apply excessive steering effort, making the wheel harder to turn.

-

Q: What distinguishes Saginaw power steering hoses from others?

A: Saginaw power steering hoses are designed for compatibility with GM vehicles and specific pump systems. They often include precise fittings and durable construction to meet OEM standards.

-

Q: Can a damaged power steering hose cause leaks or failure?

A: Yes, cracks or wear in power steering hoses can lead to fluid leaks. This reduces hydraulic pressure, resulting in steering stiffness or complete system failure.

-

Q: What steps ensure quality when making power steering hoses?

A: Quality involves using pressure-rated materials, precision crimping of fittings, and rigorous testing. Proper sizing and compatibility with steering fluid are also critical factors.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025